Why experts complain about the low reliability of cheap USB flash drives

Cheap USB flash driveswhich were never considered standard storage devices, have recently become even worse, researchers are convinced CBL Datenrettung. According to experts, drives of this type quickly lose quality, stability and durability, which makes it impossible to rely on them as reliable means of recording and storing data. Thanks to dishonest manufacturers who save on everything they can.

To maintain low flash drive prices, many manufacturers are forced to make various tricks that allow them to save money. But some allow themselves to use not just low-grade, but literally rejected components.

How do cheap flash drives differ from expensive ones?

NAND chips, marked as defective, do not necessarily have to be completely inoperable. They, just like serviceable components, allow you to record, store and read information, but, for example, they have a large percentage of non-working cells that exceed acceptable standards. Such chips are typically recycled and do not end up in a commercial product intended for sale to the end consumer.

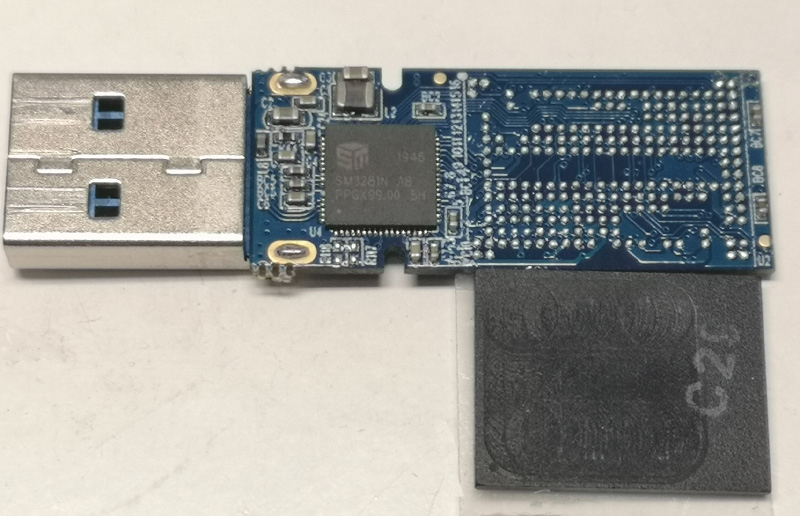

However, CBL Datenrettung found that in some cheap flash drives These are the NAND chips that are used. They clearly have not passed quality control, and in order to hide their origin, the manufacturer's name is erased from them. Therefore, it is most often not possible to track the path of defective components and, accordingly, understand how they get to the market.

Clarification: manufacturers of NAND chips and flash drives are not the same person. The memory modules themselves are produced by eminent corporations like Samsung, SanDisk or Micron, and USB drives from them can be assembled by completely different companies.

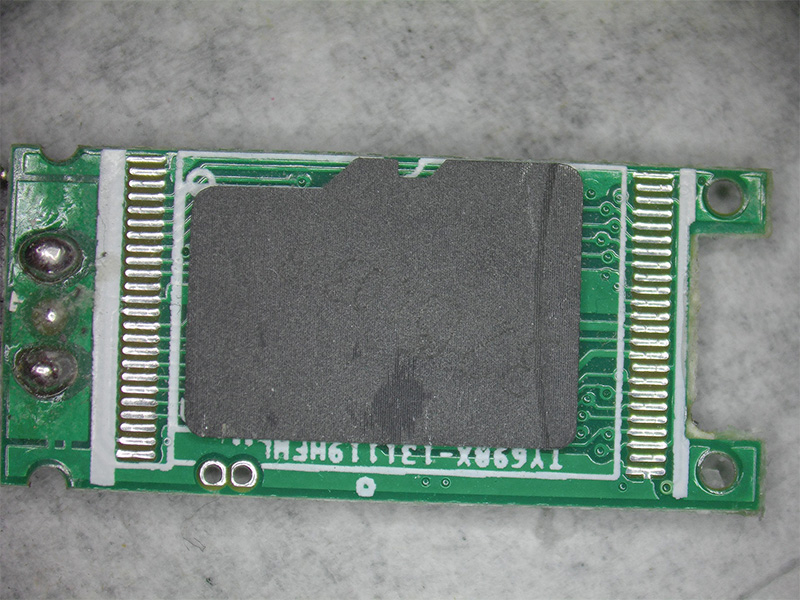

Some manufacturers go even further and use not just decommissioned traditional NAND chips intended for flash drives, but microSD cards. They are soldered to textolite boards with a USB connector, put in a classic case and sold as regular flash drives.

Such memory expansion cards are most often not of high quality. They are also selected from rejected batches with non-working controllers, which replace controllers on the board itself, or are taken from failed samples, restored and reused.

“When we opened defective USB drives Last year, we discovered an alarming number of low-quality memory chips with missing capacity and erased manufacturer's logos. Defective microSD cards without identification marks indicating their origin also serve the same purpose. They are soldered to external controllers on the board, which significantly reduces production costs,” explained Konrad Heinicke, Managing Partner of CBL Datenrettung GmbH.

The defective contents of such drives can manifest themselves in different ways, but among the main problems faced by their owners are the following:

Discrepancy between the actual volume and the declared volume

Limited number of rewrite cycles and rapid wear that is difficult to control

The simplest controller without basic resource-saving functions (block alignment, management of damaged blocks, etc.)

Low data transfer speed (due to the use of the oldest generation of USB and low-quality soldering)

Flash drive manufacturersassembled from defective components, they try to sell them bypassing traditional retail. They are often purchased for sale as fan merchandise or gift samples. This reduces the likelihood that the end user, even if the drive fails, will contact the seller – and he, in turn, the supplier – with a claim.

Flash drives with QLC memory: real reliability and service life

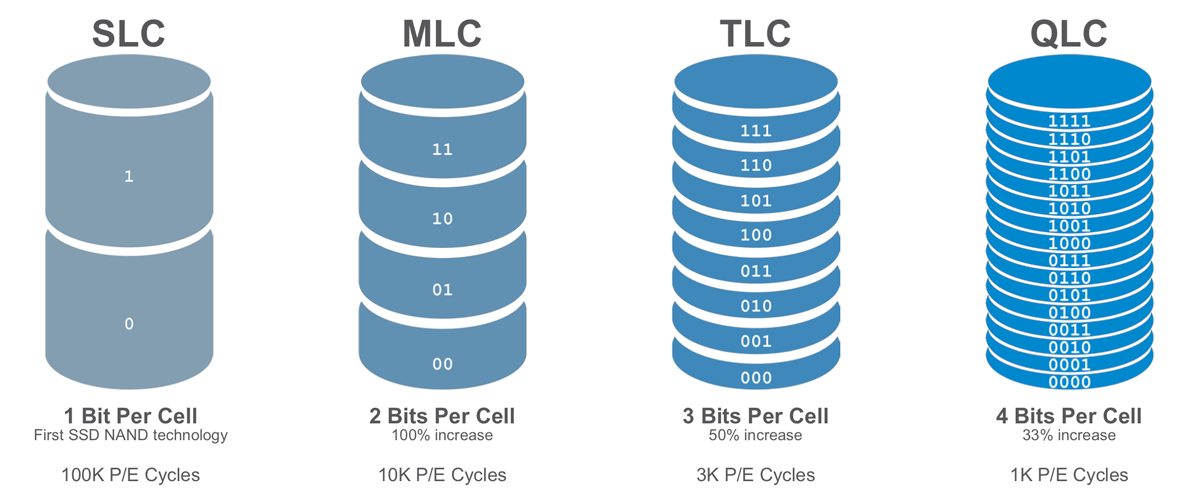

Decline reliability of USB flash drives It is also found among branded solutions from seemingly well-known manufacturers. Fortunately, it is not associated with the use of defective components, but with the transition to QLC NANDwhich are gradually replacing TLC chips.

Behind this name lies memory with four-bit cells. They are distinguished by a more affordable price, low write speed, and a resource not exceeding 1000 cycles. But QLC technology allows us to produce drives with higher capacity than before, which in the current environment is a more important aspect than reliability.

Increase data recording density on USB flash drives does not mean at all that they cannot be used for their intended purpose. Their resource is really less than that of SLC, MLC and TLC modules. But manufacturers are trying in every possible way to extend the service life of drives.

To do this, they use various mechanisms such as error tracking and correction, backup cache, and the natural decrease in write speed is leveled out using SLC buffer and other tools. For example, by allocating a small number of QLC cells, which are forced to work like SLC, which in turn reduces data processing time.

That same thousand cycles does not mean at all that if you overwrite 1000 photos on a flash drive over 1000 connections, it will fail. You need to calculate the potential service life of a drive based on two indicators: TBW (terabytes written – maximum recording capacity) and DWD (drive writes per day – permissible load per day).

They usually directly correlate with the warranty period. If it is 1 year, and per day you can write, say, 1 TB to the drive, then the TBW value (if it is not specified) is calculated by the formula: 365 * 1 = 365 TB. Not so little.

If the flash drive has an increased warranty and a higher DWD value, the performance will be even higher, regardless of what NAND chip is used in it. So put your worries aside! Just buy reliable ones USB drives from reliable suppliers and you will be happy.