Harley Davidson radio repair

It just so happened that in my free time from work and leisure time I am engaged in the repair of various equipment. And it’s not about the money. Looking at boards and finding faults gives me aesthetic pleasure. Most often, devices are brought to me with the repair of which there were problems in the services and they could not be repaired. I decided to make a post with one of the interesting repairs.

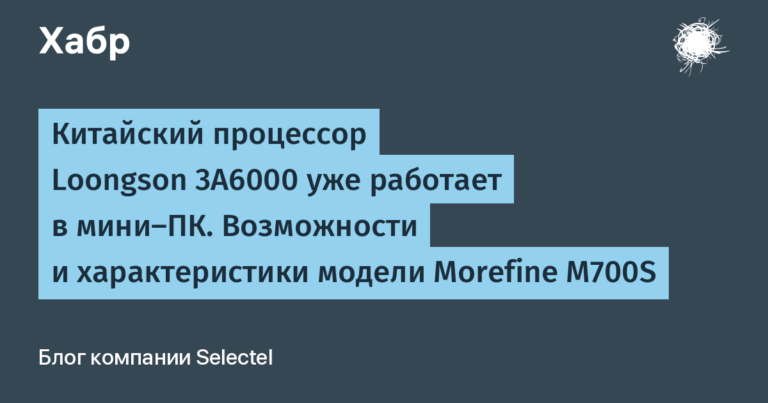

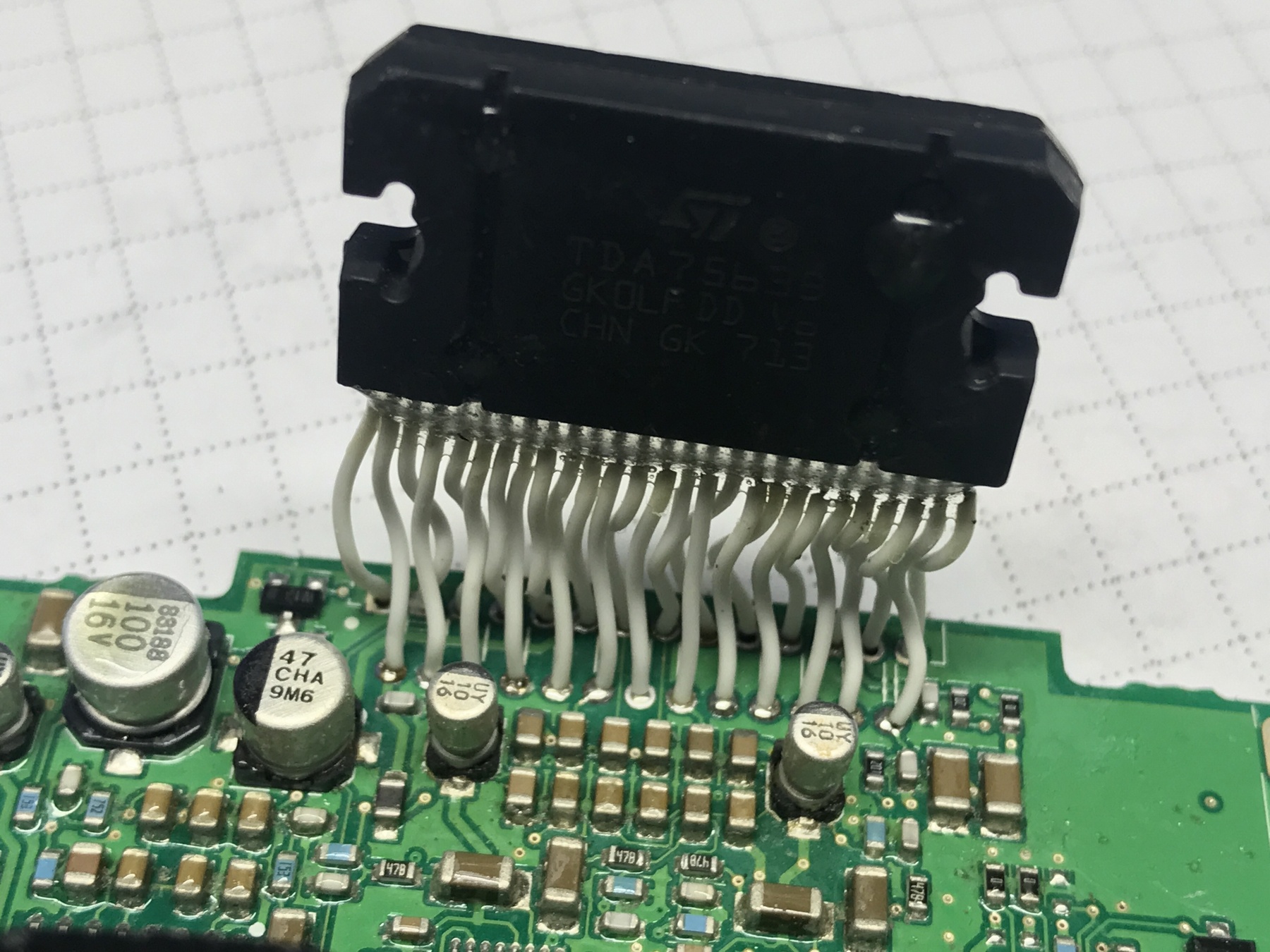

They brought me a radio tape recorder from Harley Davidson with a diagnosis – the sound does not work. I turn it on, yes – there is no sound. Having disassembled it and freed the board, I found the TDA7653B amplifier. Visually everything is great. These devices have a common problem. The amplifier chip is rigidly soldered to the board and attached to the case for heat dissipation. As a result of vibrations, the legs of the microcircuit begin to gradually break, which is visually clearly visible.

Walked with tweezers – not one staggers. Soldered just in case – does not work. The first thing that came to mind was the microcircuit burned out. I started to look with an oscilloscope what is on the legs. The power is all right, there is a signal at the input, the output is empty. Strange. Chip heating is not observed.

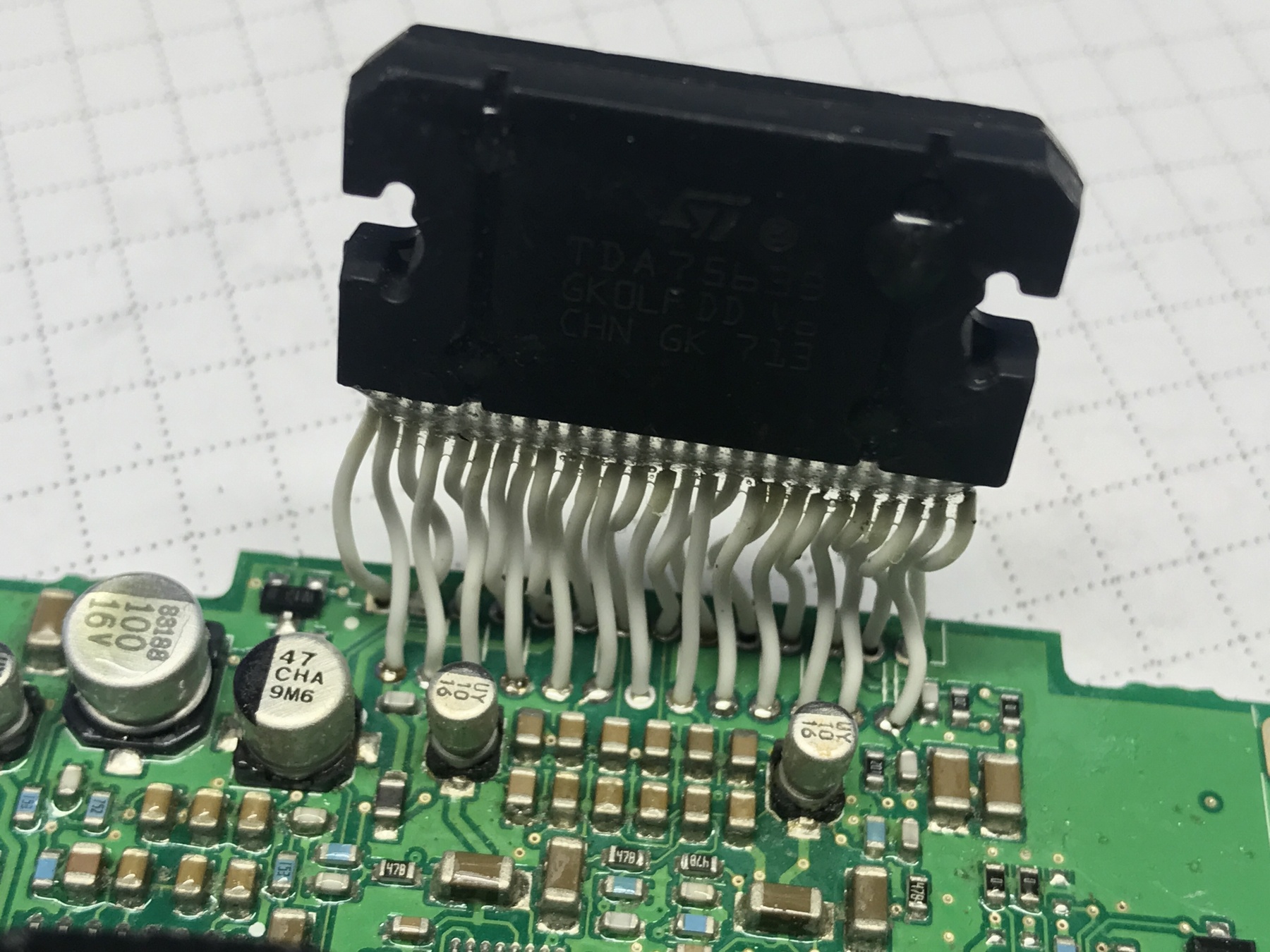

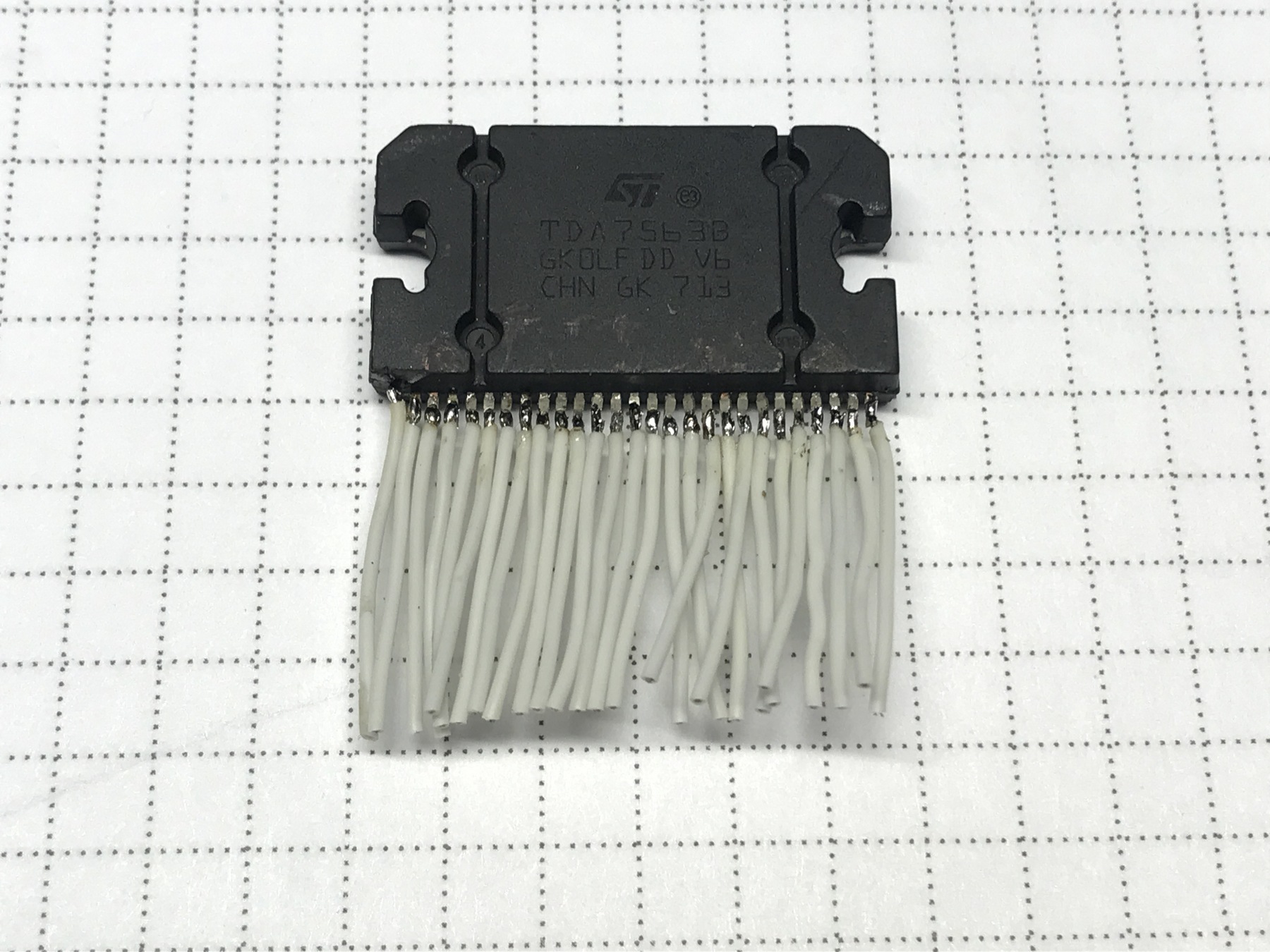

Since there is nothing to lose, I decided to thoroughly pull the legs of the amplifier. It was found that when pressed, they crawl out of the microcircuit. That is, they broke off inside! The photo clearly shows the non-tinned part of the output.

What a twist. Half of the contacts, mainly from the near edge, can be pulled out in this way. All odd-numbered pins are shorter and more rigidly “sit” on the board. Even-numbered contacts have a fold that allows them to spring back a little. I solder, I clean the contact pads.

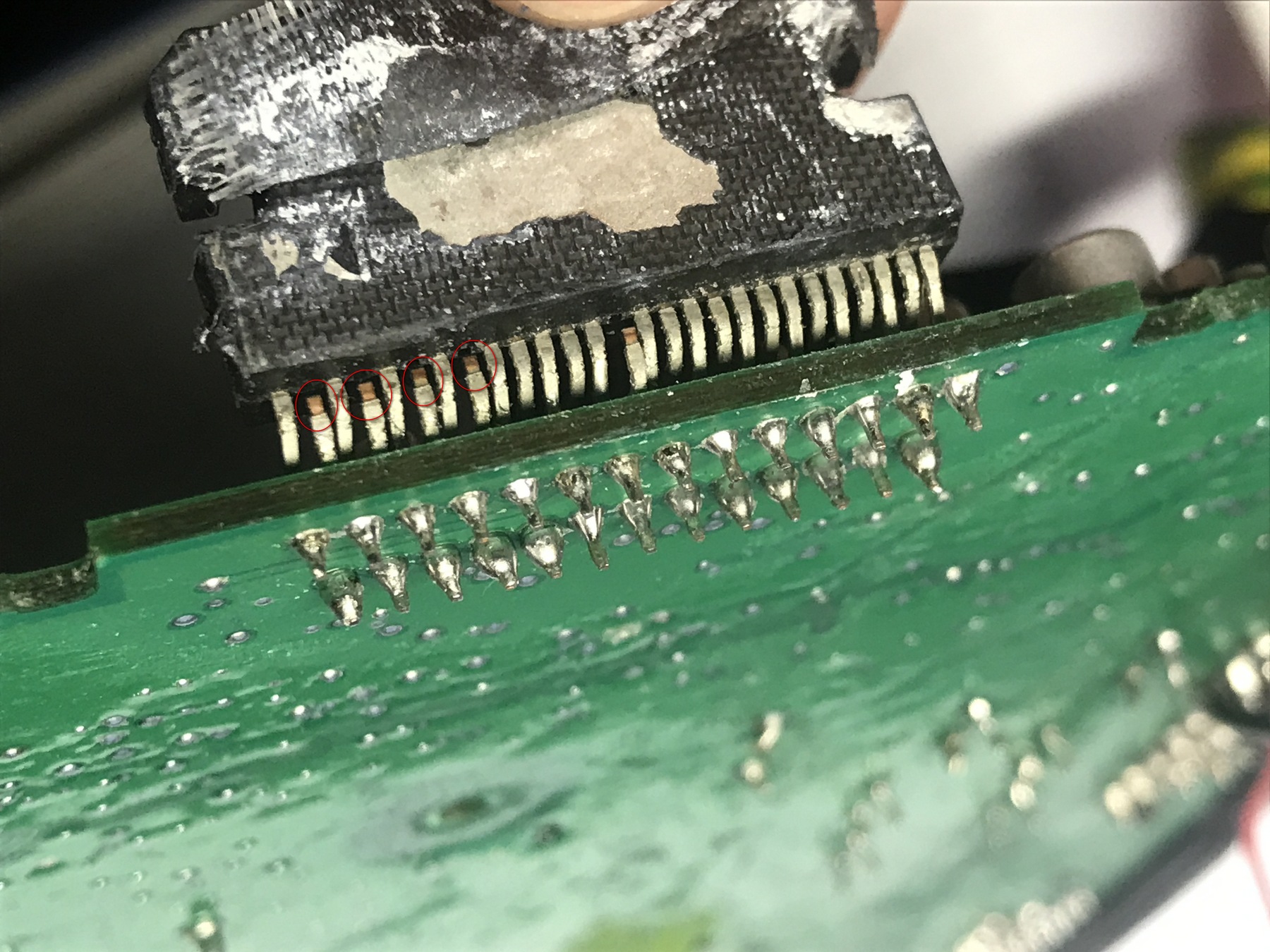

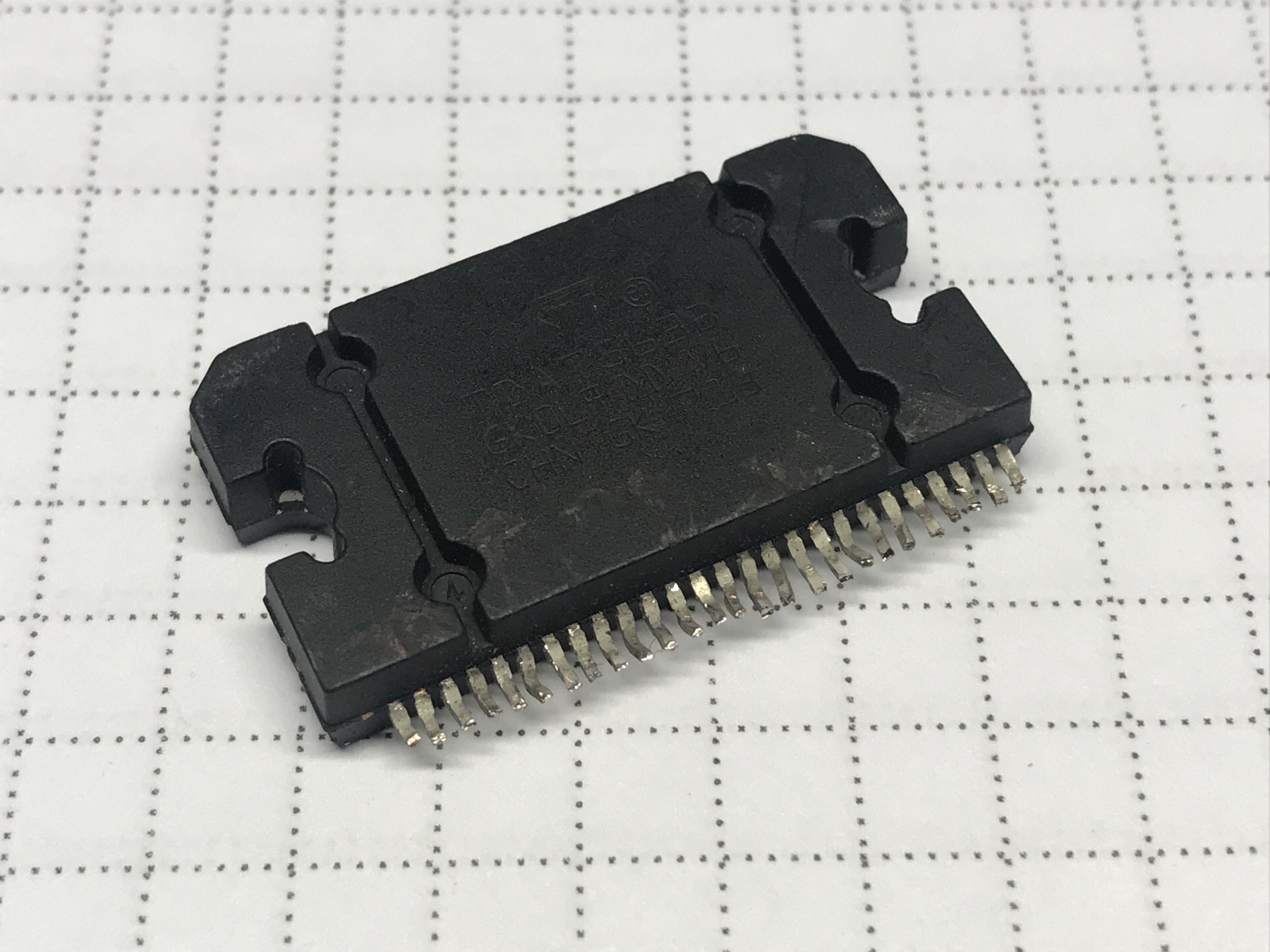

Together with the radio tape recorder, they gave me the “new” TDA7653B, with bent conclusions, on which one extreme leg was missing. One is not a problem. You can grind the case a little and get soldered. It makes no sense to solder the microcircuit “as is” – after a while it will still stop working again. Bite off the rest of the conclusions not to interfere.

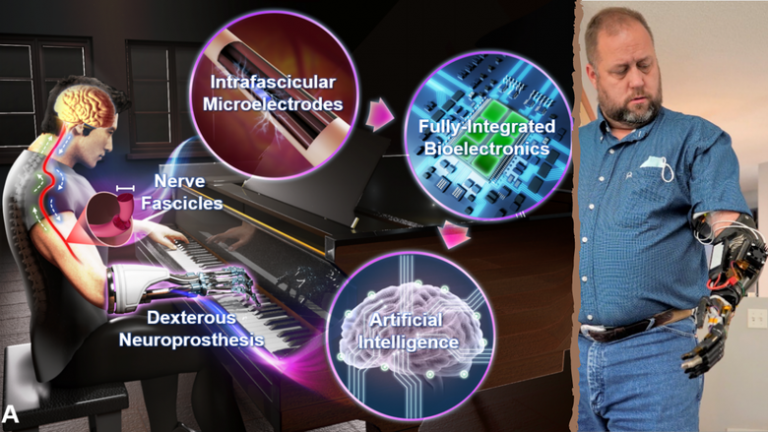

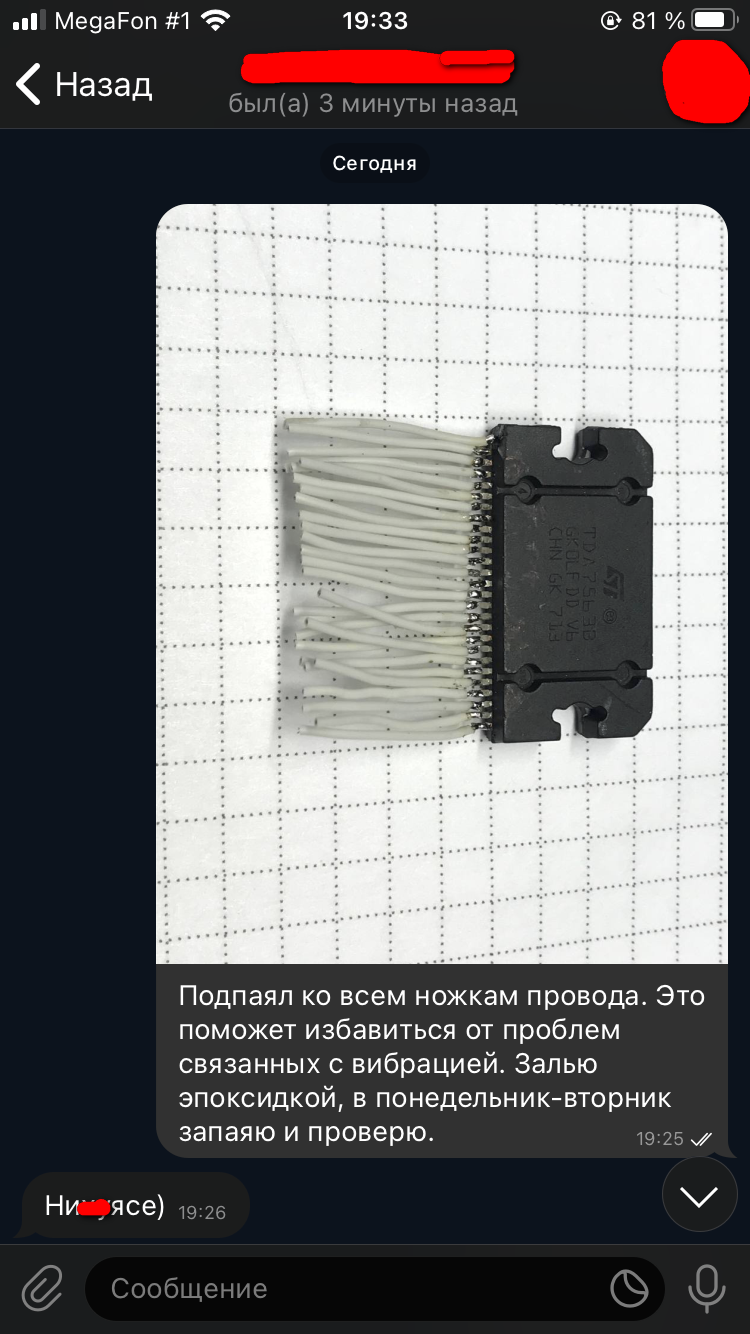

For the “new” pins, I used a soft silicone insulated wire. Firstly, such wires are more elastic. Secondly, the insulation does not melt during soldering.

It turned out pretty decent. The pin pitch allows you to solder the wires. Short circuit between the conclusions is not observed.

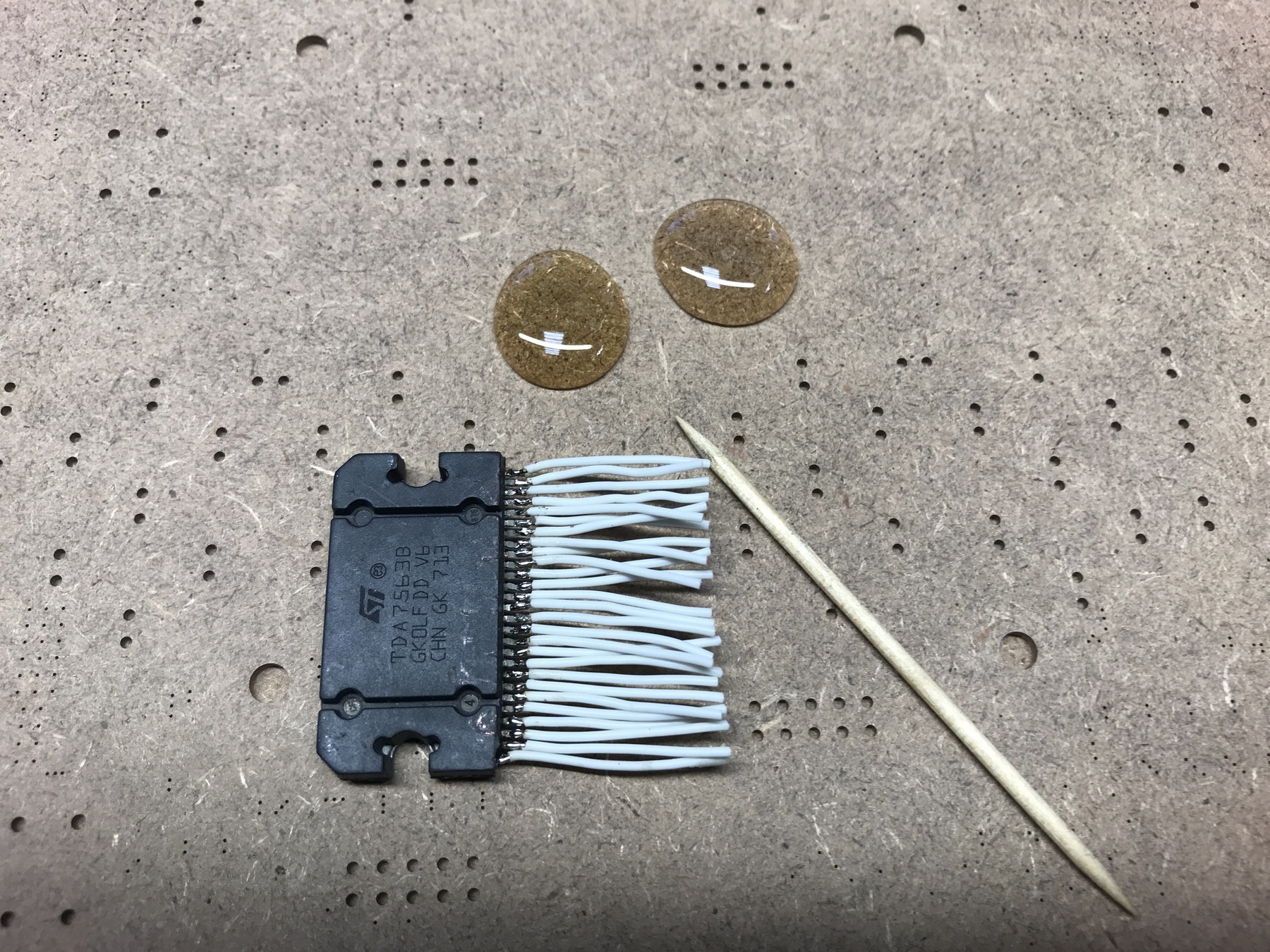

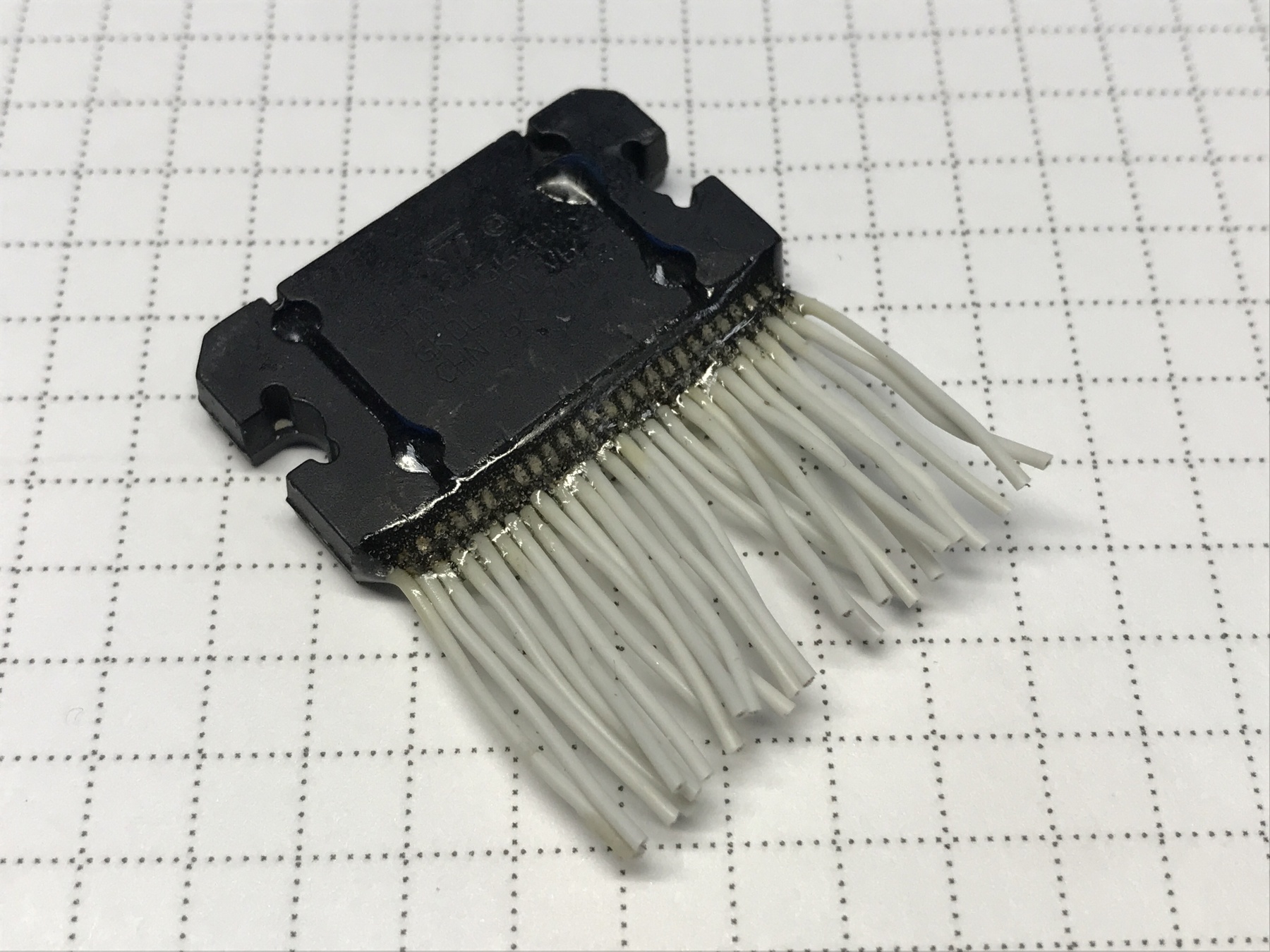

But you can’t leave it like that either. Therefore, we fill it with epoxy resin. This will reduce the likelihood of fractures at the soldering site.

That’s how it’s all good. Epoxy captured part of the insulation and the microcircuit case. Once again I looked “in the light” that there is no short circuit anywhere. You can solder.

After reassembly, the recorder worked. Is there sound. The owner is immensely happy, as he has been riding without music for a year now. Sometimes simple solutions can help complex problems.

Thanks for your attention and good luck!