Smart clothing: graphene-based temperature modulation device

Nature has no bad weather, as the famous song from the movie “Office Romance” sings. However, not everyone is ready to agree with this statement. Someone like the cold, someone prefers the heat, someone does not care. But I belong to those people who will complain about the heat and cold, give us a comfortable +20 ° C. Unfortunately, not always and not all lovers of a neutral climate have the opportunity to live in regions where it exists. Now the summer is in full swing, the suffocating heat is only occasionally interrupted by short-term thunderstorms that do not really help. If nature is not ready to meet us, then it is worth doing something ourselves. Today we will get acquainted with a study in which scientists from the University of Manchester (Great Britain) developed smart adaptive tissue that can lower the body temperature of a person wearing it on hot days. What formed the basis of smart tissue, how did the development process proceed, and what additional properties and applications are there for this invention? We will find answers to these questions in the report of scientists. Go.

Study basis

Before telling us about their creation, scientists note that progress in the field of user electronics in recent years has been leaps and bounds. Literally every day something new and unusual appears. However, there are a number of limitations that prevent certain developments from moving from the laboratory test stage to the mass production stage. In the aspect of the production of smart tissues, the main problem is the difficulty of integrating electronic / optical materials into the tissue fibers. The easiest option in wearable electronics is the creation of separate gadgets (bracelets, watches, etc.) that do not require integration into another system (in this case, fabric), but the range of capabilities of these devices will be limited.

According to scientists, in order to achieve intelligible results in pairing electronics and fabrics, it is necessary either to change the technology of fabric production, or to use non-standard materials for the electronic part of the wearable device.

One such material is two-dimensional graphene. However, in previous attempts to use it, scientists relied more on its electrical conductivity. In this work, the emphasis was placed on the optical component, i.e. The idea was proposed to use graphene as an optical platform.

Thermal radiation from multilayer graphene can be modulated electrically through intercalation * ions.

Intercalation * – reversible incorporation of a molecule or group of molecules between other molecules or groups of molecules.

In this study, scientists present to our attention an optical textile technology based on the integration of dynamic infrared devices into textiles based on electrically tunable graphene formed by chemical vapor deposition (CVD).

Research results

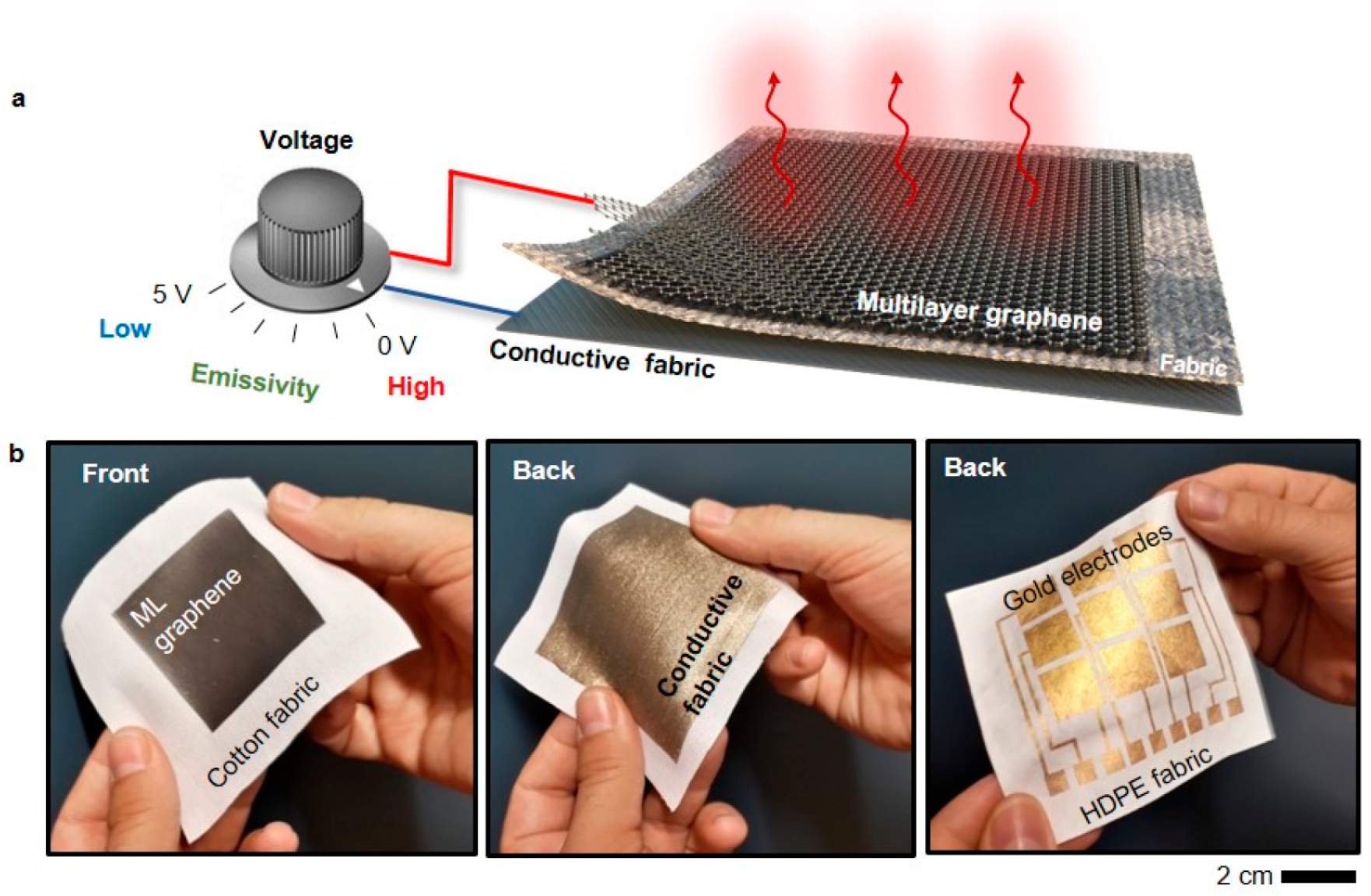

The devices consist of combined layers of an infrared transparent polymer layer, multilayer graphene grown using the CVD method, a layer of tissue separator and conductive fabric (device diagram on 1a)

Image No. 1

Production begins with the cultivation of multilayer graphene films on nickel foil. A thin polyester (PE) film, which functions as a protective layer transparent to infrared radiation, is laminated to multilayer graphene before etching the Ni-foil. Graphene on a polyester sheet is attached to the fabric using hot-melt adhesive.

One of the important points of this development is ease of use and practicality, so it was necessary to make sure that there is good adhesion between graphene and the substrate (fabric). This has been done through several washing cycles and through mechanical compression tests.

Next, an ionic liquid electrolyte (BMIMPF6) was deposited on the back electrode (conductive tissue), which subsequently diffused into the textile substrate. Textiles act as a separator and ion-conducting layer, providing ionic motion when a voltage difference is applied to graphene and the back electrode.

On the 1b examples of manufactured devices on natural (cotton) and synthetic textile materials (polyester) are shown.

The electrochemical stability of the rear electrode plays a crucial role in the long-term stability of the device. Various materials were tested as the basis for the back electrode: conductive silver-based textiles, stainless steel mesh, gold plating, graphene and reduced graphene oxide.

An array of back electrodes and wiring on textiles were made using photolithography followed by metallization and process separation *.

Separation * – in microstructuring technology, it is a way of creating structures of the target material on the surface of the substrate using a “sacrificial” material (for example, photoresist).

The resulting pixel electrodes allow the determination of dynamic infrared structures on a continuous graphene layer using selective intercalation.

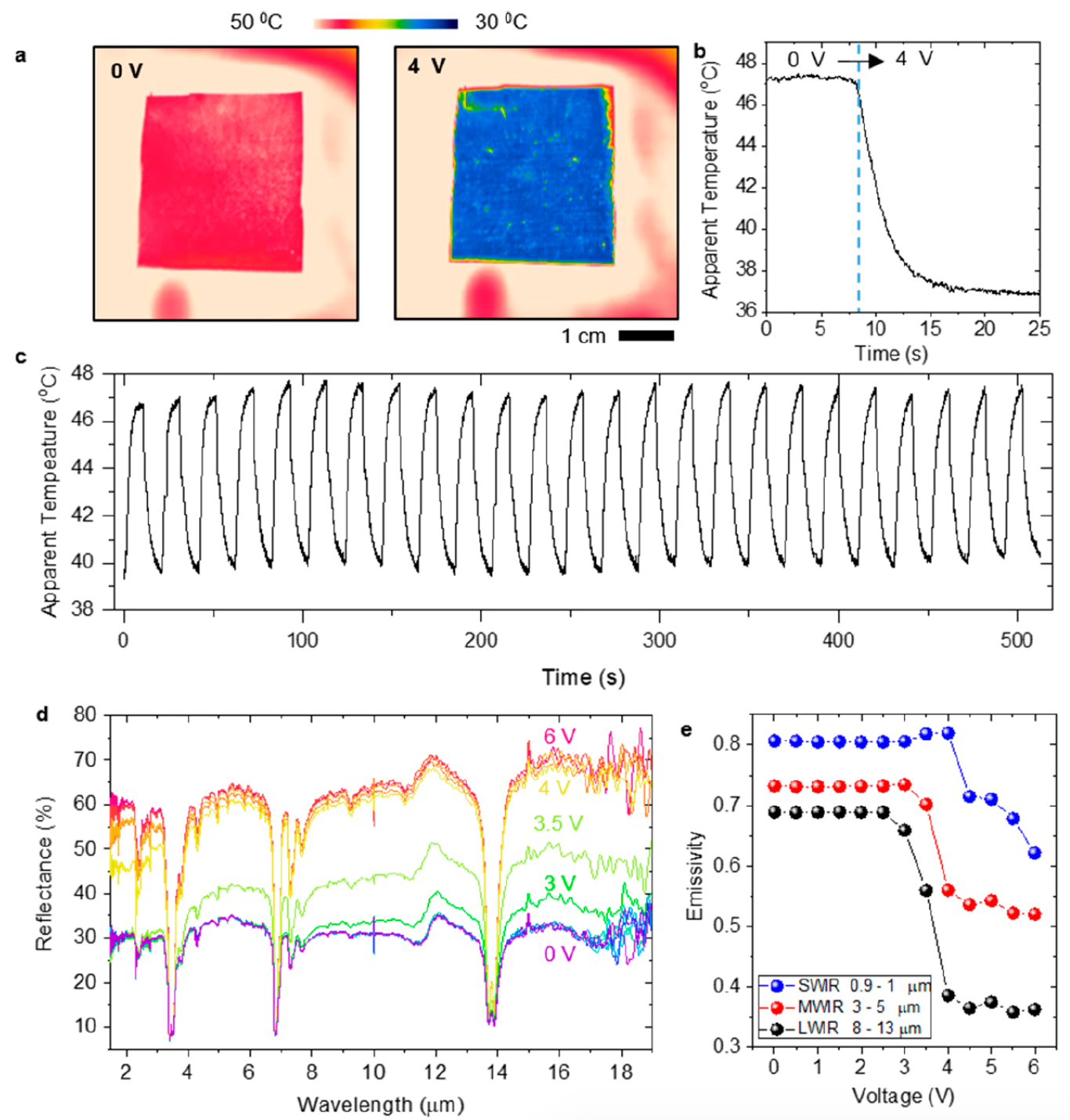

The principle of operation of the devices is based on the reversible intercalation of ions into graphene layers and modulation of its electrical and optical properties. At 0 V, multilayer graphene has a high infrared absorption, which leads to high emissivity, revealing the actual temperature of the device (2a)

Image No. 2

When a sufficient voltage difference (> 2.5 V) is applied, the ionic liquid intercalates into graphene layers, increasing the optical conductivity and suppressing the emissivity, thereby hiding the actual temperature of the device. Thermographs of the device were recorded using a long-wave infrared camera, which visualizes images according to the Stefan-Boltzmann law:

P = εσT4

where P is the amount of incident thermal radiation on the matrix bolometers *; ε is the emissivity of the surface; σ is the Stefan-Boltzmann constant; T is the surface temperature in Kelvin.

Bolometer* – thermal radiation receiver (converts the energy of absorbed electromagnetic radiation into heat).

Textile devices in direct thermal contact with heat sources, such as the human body, to prevent false shielding of the temperature of the source. In addition, graphene functions as a layer with high thermal conductivity, which doubles thermal diffusivity in the textile plane, improving thermal conductivity from the source to the surface.

The time response of the devices was obtained by recording a video with a thermal imager to obtain a change in the apparent surface temperature (2b)

Dynamic change of infrared radiation on a cotton device.

Full intercalation (suppression of emissivity) takes ~ 5 s when the device current is not limited. It is worth noting that these measurements were carried out in laboratory conditions (21 ° C), limiting the minimum apparent temperature.

Devices can repeatedly cycle between high and low emissivity states (2c), however, the excess of the electrochemical window of the electrolyte affects the performance of the device.

Modulation of the emissivity was quantified by measuring the reflection in the infrared and near infrared ranges using an infrared Fourier spectrometer (FTIR) equipped with an integrating sphere. At 0 V, the reflection coefficient of the internal device is almost flat (2d) and amounts to about 30%, with the exception of absorption in the upper polyester film at wavelengths of ~ 3.4, ~ 6.8, ~ 13.9 μm, and absorption in the atmosphere (e.g., CO2, H2O).

Demonstration of the adaptive infrared textile device.

In the range of spectral sensitivity of the thermal chamber (8-13 μm), such absorption is minimized by careful selection of the upper protective film. The emissivity (or absorption coefficient) is calculated as 1 – R, where R is the reflection coefficient, since light does not pass through the device. As ions intercalate graphene layers, the Fermi energy and optical conductivity of graphene increase, thereby increasing the reflectance of infrared radiation.

The average emissivity of the device in the wavelength range of 8–13 μm is quite high (± 0.7) for 0 V and is maintained at that value up to a threshold voltage (± 2.5 V) with a subsequent sharp drop to ± 0.35 at> 4 V (2nd), which agrees well with the thermograms at 2a.

Modulation of the emissivity covers both the long-wave infrared (8-13 μm) and the medium-wave infrared (MWIR, 3-5 μm) range. In MWIR, however, the polyester film exhibits significant absorption due to the stretching regime of C-H bonds, which is independent of the applied voltage, limiting the range of modulation of the emissivity to 0.7-0.5 (2e) It follows that any devices operating in this wavelength range require a non-standard protective layer.

Another effect of the polyester layer is the increased emissivity of the surface due to thermal extraction with polyester, in which the refractive index is greater than that of air.

Modulation of emissivity (0.2–0.4) was also observed in the short-wave infrared range (SWIR, 0.9–1.7 μm). But the modulation in the visible spectrum was negligible due to insufficient doping of graphene.

It is possible to improve modulation in SWIR and visible range by using an ionic liquid with a large electrochemical window, which will be compatible with textiles.

Given that the fabric must be stretchable and flexible, the graphene elements used must act accordingly. However, multilayer graphene does not stretch and does not bend due to mechanical stress. Therefore, a non-standard curved graphene design was used in the development, which ensured a strain level of up to 60%.

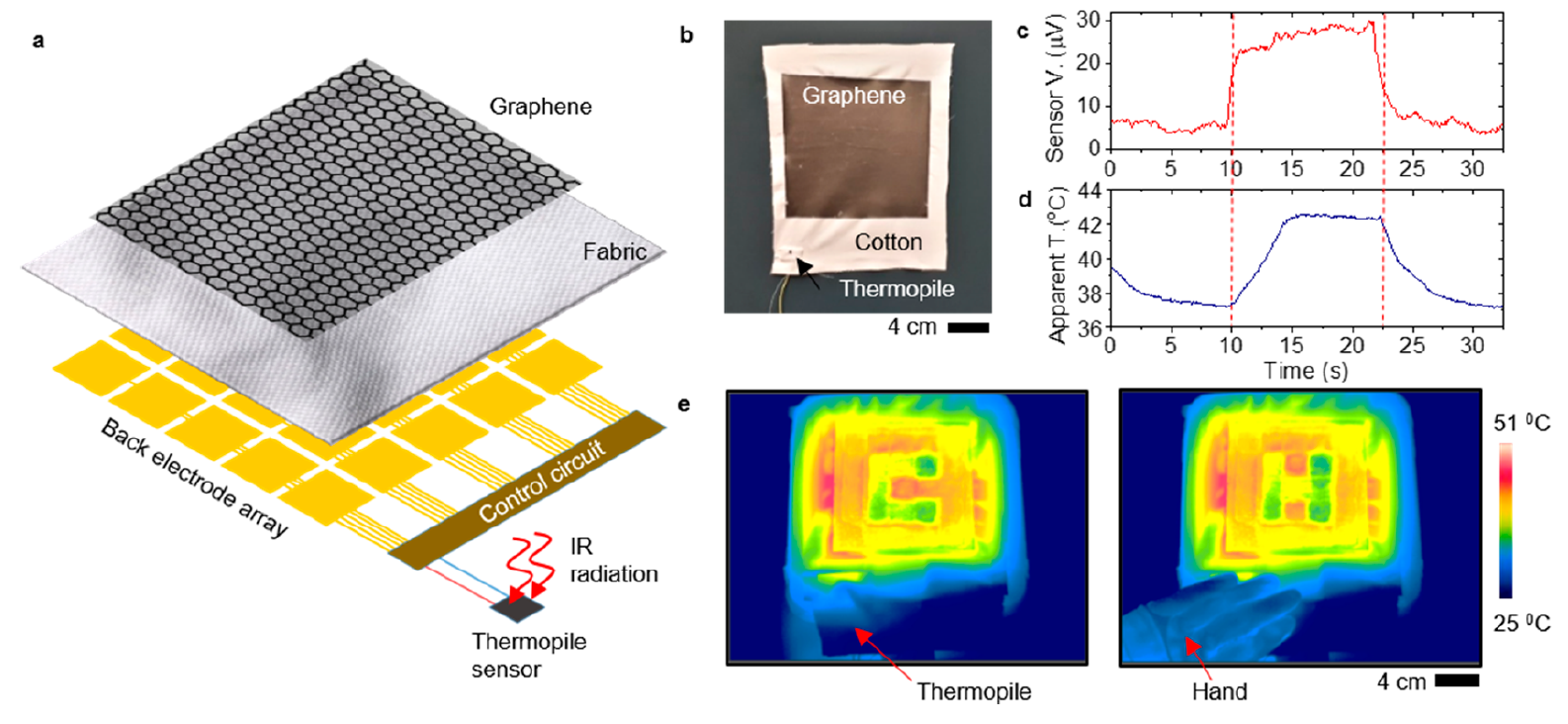

Image No. 3

All problems with flexibility and mechanical stress can be solved through the use of arrays of electrodes in a single element. On the 3a An example of such a configuration option with an array of 25 individually addressable electrodes and a thermal battery sensor is shown. As the active layer, a large solid sheet of multilayer graphene on cotton fabric was used (3b) Each electrode controls a 2 x 2 cm emissivity. An external electronic circuit has been programmed to respond to a thermal signature from the sensor. Graphs 3c and 3d show the sensor signals and the apparent temperature of the active pixel (control area 2×2).

A multi-pixel textile device displays the letters “C” or “H” (indicating cold and hot) by adjusting the emissivity of the corresponding pixels that respond to the presence / absence of a hot object above the sensor. On the 3e Thermal images of the operation of the device when interacting with a human hand are shown.

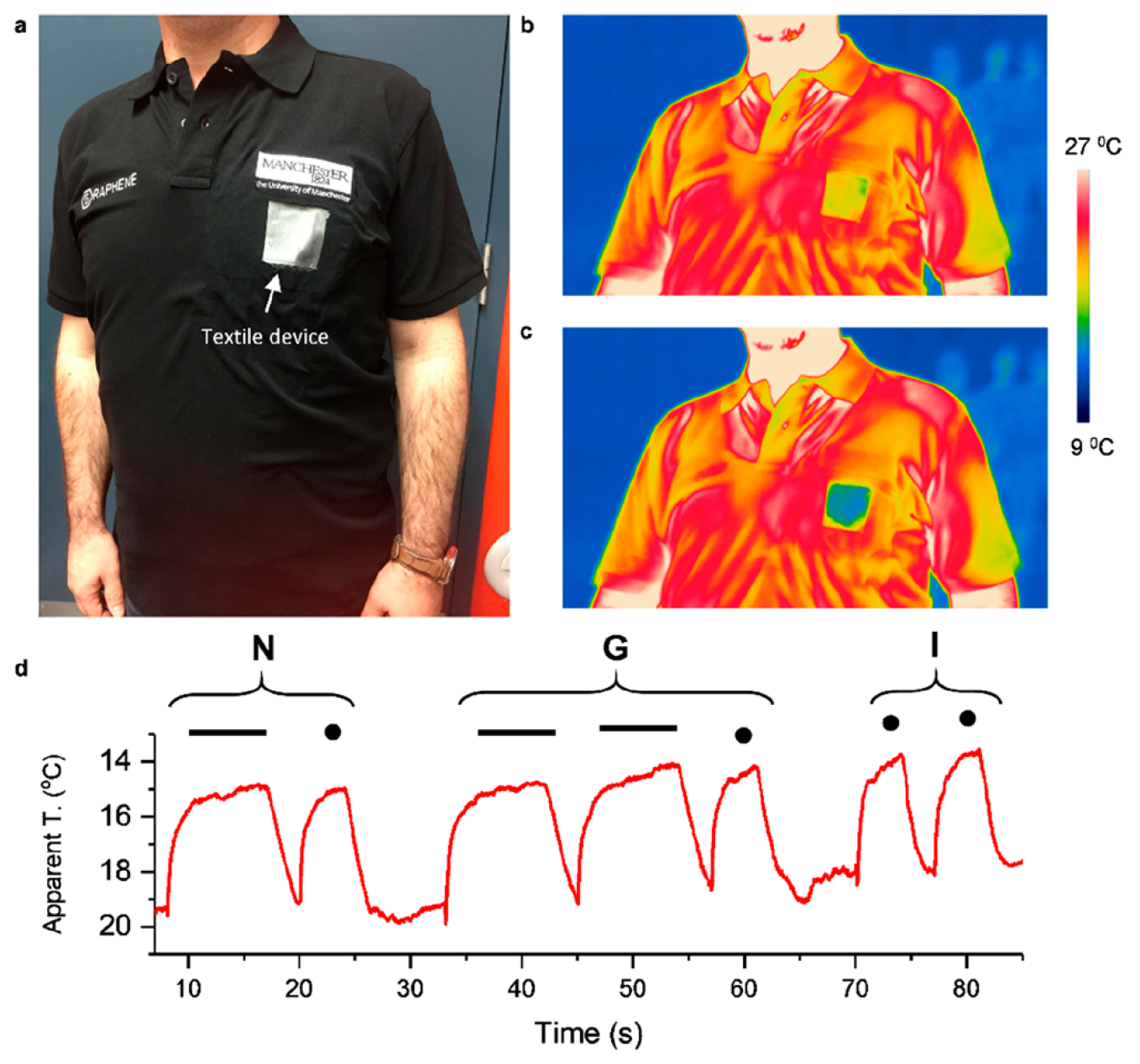

Further, the scientists conducted an actual practical test of the device embedded in a regular T-shirt. Due to the natural temperature of the body, in the environment, the human body emits about 100 watts of infrared light mainly in the LWIR range. This spectral range also coincides with the atmospheric transmission window, which allows the propagation of light emitted by LWIR over long distances.

The T-shirt device was made by laminating a 6×6 cm graphene / polyester film directly on the surface of a T-shirt made of 100% cotton and a stainless steel mesh on the back (4a)

Image No. 4

To transmit the encoded signal, a microcontroller was used, which was programmed to transmit the letters “N”, “G” and “I” with Morse code. Dashes and dots were created by suppressing the apparent temperature for a long (9 s) and short (3 s) time.

On the 4b and 4s infrared images of a T-shirt are shown in states with high and low emissivity, and the scale on the right shows the apparent temperature recorded from a distance of 3 m.

Using a microcontroller allows you to build more complex circuits on textiles, which, in turn, provides more secure communication protocols, for example, initiating communication when receiving external triggers. And the human body in this configuration can serve as a source of energy.

In this experiment, the communication speed using a single patch is limited by the intercalation / deintercalation process, which scales depending on the area of the device.