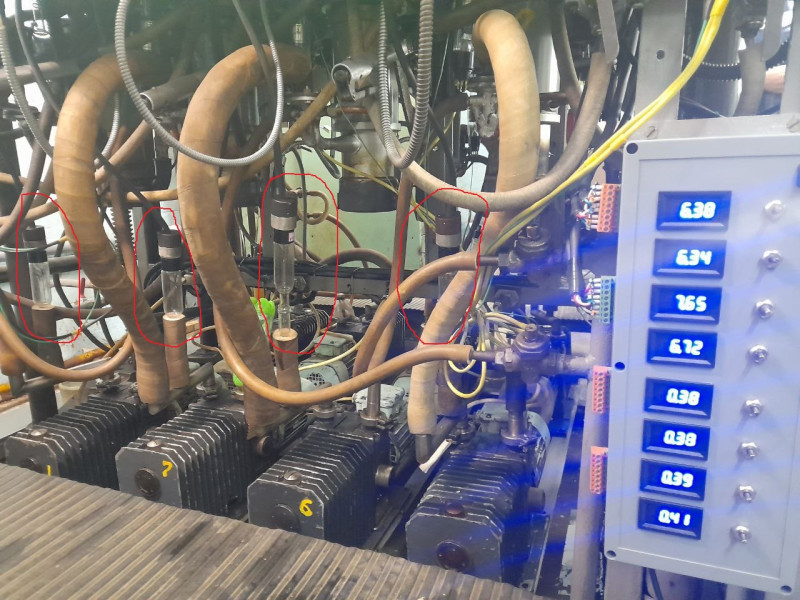

Low-vacuum manometric system on an 8-position pumping station

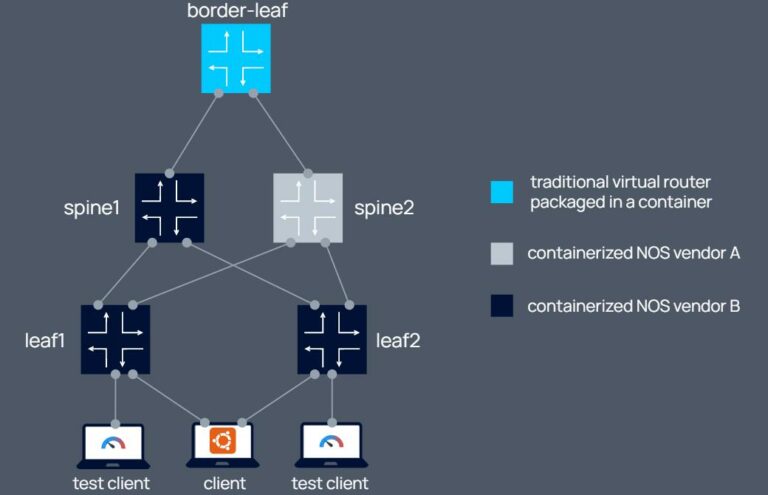

The assembled system looks like this:

Circled in red are 4 vacuum thermocouple heat sensors of the PMT-2 type, which measure the vacuum created by mechanical pumps. Our original indicator device differs from those available on the market for such lamps in that it works simultaneously with 8 lamps of the PMT-2 type. Those. does not require any homemade switches for sequential connection of lamps to the measuring channel of one device (as was done in the USSR by “Kulibins” and is still done in many places). Taking into account the fact that the useful signal from the lamp thermocouple is 0 – 10 mV (by the way, the millivoltmeter indicators in the photo show the value of this signal), then all sorts of intermediate switches shamelessly distort it. In addition, switching lamps to the input of one standard device also introduces operator error, since no one waits for the thermal conditions of the connected conditionally “cold” lamp to establish (this usually takes up to 60 seconds or more), so it is almost impossible to compare the readings between such sensors connected by the operator no possibility.

When we designed this vacuum indicator, we proceeded from the desire to make the most simple (inexpensive) device, which, moreover, could be scaled up. Therefore, the basic module of such an indicator consists of 2 channels of a differential voltage amplifier on an op-amp of 1000 times (to easily interface with Chinese measuring heads) and 2 channels of a current-voltage converter of 100 mA = 1 Volt. Considering that the voltage on the heater of the PMT-2 lamp is about 1 Volt, the op-amp does not even need bipolar power. To sufficiently stabilize the current through the heater of the pressure lamp, it is permissible to use a powerful trimming resistor that generates a heating current from a stabilized voltage source of 5-7 Volts. The red, non-fixed button immediately switches all indicators from the thermocouple voltage measurement state to the heater current measurement state.

This vacuum indicator, operating in the range from 10 Torr to 0.001 Torr, also has an analog output to the process control system (we have developed an interface module for this), and the process control system can, using 3 digital lines, select the channel from which to remove the analog signal 0 – 10 Volts. The indicator has only one switch (power supply 220 Volts) and one button, pressing which switches all measuring channels to the mode of indicating the heater currents of their sensors. Trimmer resistors allow you to set your current in each channel with an accuracy of +\- 1 mA in the range of 80 – 160 mA. In this case, the equipment requires the installation of 8 pieces of PMT-2 at once, but for other equipment we have assembled two more versions of the indicator, for 2 and 4 channels of vacuum indication.

In conclusion, a view of the PMT-2 lamp simulators to check the correct operation of the fore-vacuum indicator:

The next photo shows a similar forevacuum indicator, only with 4 channels and without the ability to connect to an automated process control system.

We have been actively using the devices for production purposes for several months now. People who previously always used devices like VIT-2 (VIT-3) quickly got used to it and are very pleased. A good friend took the board from me (without housing and indicators) to try it at his factory, although there is a state-owned one there. registry “Meridates”.