Is the base of the cooler convex?

Is a convex base a defect?

This question can be found from buyers of products from Noctua, Ice Hammer, Thermalright, ID-COOLING, Arctic Cooling and other famous brands.

Noctua on this matter speaks following:

“We design our radiators specifically to be convex so that pressing in the center gives better heat distribution.”

Thermalright:

“The convex copper base design ensures maximum thermal conductivity between the processor and heatsink.”

DeepCool:

“To ensure maximum cooling, the base of our coolers has been CNC machined into a convex shape.”

What experts say:

“The difference between the thermal conductivity of a cooler with a flat surface and a cooler with a convex base is insignificant. In some cases, one is effective, in others, the other. The difference is 2-3 degrees.”

What is the reason for this?

There are no perfectly smooth processors

Any processor from the factory has a curvature. The reason for this is the processor cover; it is a stamped sheet of metal with various irregularities, roughness, waves, etc.

This is what an Intel processor looks like under a microscope:

And this is an AMD processor:

Making a smooth processor cover (growing atoms in the lab) costs more than the processor itself. But this is not necessary. The surface of the cooler under a microscope looks similar.

Cooler surface:

Thermal paste

Thermal paste is good for bridging the gap between two surfaces.

But this is only in theory. In practice, thermal paste does not provide 100% contact between two surfaces.

In the following photo we see how the thermal paste adheres to only 60% of the surface:

The rest of the surface is grainy and filled with air bubbles. Air is 100 times less efficient at conducting heat than thermal paste. The thermal conductivity coefficient of thermal paste is 5 W/(mK). Air – 0.03 W/(mK).

So why couldn't the thermal paste provide smooth contact?

Firstly, thermal paste has a limited scope. It is applied in a thin layer, and is not intended for leveling very curved surfaces (with a difference of more than 0.1 – 0.2 mm).

Secondly, as we have already said, all processors are “crooked”.

Numerous laboratory experiments confirm that each processor has its own imprint on a flat surface.

This is where coolers with convex bases come into the picture.

CPU

First, let's look at how the processor works.

The CPU chip is placed on a printed circuit board (textolite). The chip contains a thermal interface up to 1 mm thick. The rest of the space is filled with air.

The processor cover is made of copper with a thickness of 1.5 mm.

This design allows you to easily support a weight of up to 5 kg (without deforming the crystal).

Intel vs AMD

Intel places its dies centrally:

AMD is characterized by several crystals:

AMD crystals are equidistant from the center.

Concave Intel CPU Cover

12th Gen Intel Processor Buyers in 2022 discovered, that their processors warp (by themselves) when installed in the LGA 1700 socket. Intel acknowledged the problem, but stated that such warping does not threaten their products. The bend of the cover complied with the permissible standards.

We don’t know what the current standards are for permissible concavity of processors. But the manufacturers definitely have such information. And if you bought a cooler with a convex base, then feel free to press it all the way.

Strong pressure?! How strong?

Quite often you can come across the question: How hard can I press the cooler? Will the processor break?

To answer this question, let's look at the link in more detail:

Cooler + CPU + Motherboard.

The cooler is putting pressure on the processor. The processor is pressing on the socket. The socket is pressing on the motherboard. Who does the motherboard put pressure on?

The motherboard, meeting the powerful pressure of the cooler, distributes it over the surface of the backplate.

Intel and AMD guarantee that their backplates can withstand the load from all types of coolers and no deformation occurs.

Now let's move on to practice.

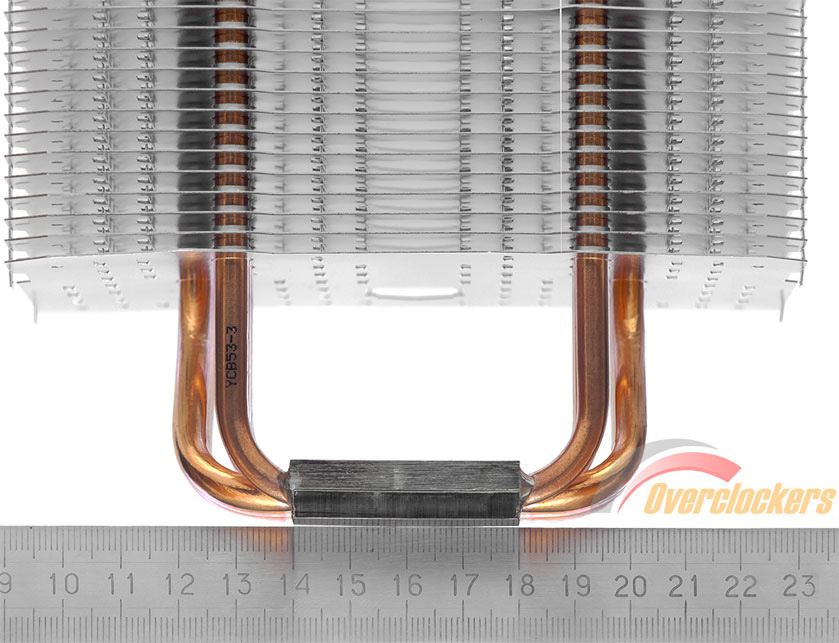

Cooler installation

First, install all the necessary fasteners on the motherboard, as required by the manufacturer.

Then apply a thin layer of thermal paste to the processor and cooler base. The brand of thermal paste does not matter in this case (we used GD900). The pressing force in the center plays a role.

Carefully (from all sides) make sure that the clamp is exactly in the center. In our case, the base of the cooler turned out to be larger than the size of the processor (40*40 mm); alignment required skill.

In the last step, tighten the clamp screws until they are tight. The cooler should not wobble, droop, sag or show any signs of being loose. The cooler must “tightly” cling to the motherboard and create strong contact with the processor.

Tests

Test stand:

Processor: AMD Ryzen 7 5700X.

Cooler: Thermalright Macho rev. A (with convex base).

Mother: ASUS TUF Gaming B450-Plus II.

RAM: Kingston Fury Beast DDR4 3200MHz – 32 GB (2x16GB).

Case: DeepCool Tesseract.

Power supply: Be quiet 500W.

Room temperature: 25 degrees.

*The side cover of the housing is open.

The OCCT stress test warmed up our processor to 63 degrees (maximum value at the peak point).

The AIDA64 stress test also warmed up our processor to 63 degrees.

Results

Coolers with a convex base are a universal solution for both Intel and AMD processors. This is a conceptual solution for efficient cooling. This is not a marriage.

Beware of sanding.

And good luck to you.

Write in the comments what kind of cooler you have and how it cools.