Good idea

We often behave in contradictory and illogical ways. I return from the dacha in the evening and already 300 … 400 meters away I find out that there is a traffic police crew in front, there is time to fasten the belt or turn into some adjacent dark street. But everything is in order, my license and insurance are valid, and my seat belt is fastened. Law enforcers ignore my battered Kiya and I roll on. As a sign of solidarity, I warn the oncoming Hyundai about the impending danger. If everyone followed the rules, then the roads would be calmer, and the driving culture would be higher. It is extremely illogical to warn potential intruders that they are in for an ambush.

Or another example, suppose relatives come to visit you. In this case, the apartment will crackle with frequency, things are laid out on their shelves, the dishes and stove are washed, a speck of dust will hide behind the closet. And then we wonder why, before the arrival of some big shot, the city is transformed beyond recognition. And the streets noticeably freshen up, and the lawn appears, and even the holes on the roads become noticeably smaller. After all, on the contrary, it is necessary to show that there are problems, there is not enough money, it’s bad, they say, we live. But it can be seen in the nature of man inherent desire to appear better than it really is.

Incidents constantly happen in development, the chosen course turns out to be a dead end or useless, or even completely absurd. Unfinished projects hang in the memory like a heavy burden, sometimes they evoke nostalgia, sometimes they take up space in the back room, sometimes they stay “until better times.” But be that as it may, they are useful.

There are people who generate ideas continuously, drawing inspiration almost from thin air. Their eyes are constantly burning, any undertaking seems promising, exciting and commercially profitable. “I see the goal, I see no obstacles,” we joked about the director of one company in which I once happened to work. Such managers often achieve success, occupy leadership positions. Surely many had to work in an organization headed by a person of this type, the originality of ideas and the courage of whose proposals periodically discourage the engineering staff.

Some undertakings literally hover in space. As cats catch the slightest vibrations of the air with their antennae, so technical specialists can easily determine the Main Stream. If you do not believe me, ask a question in the chat … how is it. Of course, over time, the focus changes, and people are eager to become a C #, Phyton or Java programmer, or to collect some popular “thing”. About ten years ago, for example, many people made machine tools with numerical control on their own. Staying away was simply indecent.

Machine tool with numerical control

As for me, making a three-axis milling machine with your own hands is a good idea. Student years, there is no money for Chinese, and getting a finished piece of iron is not at all the same, the spirit of competition is lost. The Internet is teeming with different design options, some assemble mechanics from wood, some from aluminum, some buy ready-made drivers for stepper motors, and some make it themselves. I was inspired by the design proposed Pavlov Sergey. No claim to novelty, but high quality, reliable, simple enough. It was also decided to make mechanics from metal, so it is stronger, electronics – by laser-ironing method. As guides, I chose pins with metric threads along which brass bushings should move. The vertical guides are held on the latter, and then the story repeats for the Y and Z axes.

When the idea is on fire, the business is glued. A couple of sketches on paper, several trips to the hay market for dural plates, several appeals to the turner. The shafts must be ground to the diameter of the bearings, which, in turn, must be mounted in the supports. Everything is placed on the table, held by steel corners. The axes of the horizontal table are synchronized with a belt, saving on one stepper motor. For electronics, we use the simplest circuitry, a PIC16F84A microcontroller in a DIP package and a driver on an SLA7029M chip.

For better or worse, but the first prototype was assembled in a few months. True, I didn’t know the word “prototype” then, I thought everything would work out the first time.

When there is no plan, the project moves according to the principle “where it will lead”. It was possible to achieve horizontal movement, but the resulting gaps, backlashes and opposing forces turned out to be incompatible with life. If the carriage somehow moved at idle, then under the slightest load the engine shamelessly skipped steps. Alignment left much to be desired, brass bushings were ground from the pressure of the shafts, a kind of analogue of a bad wheel alignment of a car. In general, it made no sense to continue with such mechanics, the project was frozen.

Circle, spiral or straight line, philosophers argue on the topic of the passage of time, while (1) will answer the embedded programmer. So the ideas seem to circulate in a circle. Making a three-axis milling machine with your own hands is such a good idea! Is it possible to throw it. Having gained experience at the first job, got acquainted with the basics of designing electronic devices and as a practice with Sold Works, after a couple of years it was decided to breathe new life into the idea. A “serious” approach requires financial investments, so a spindle with a frequency converter, guides, sliding bearings, end switches and corrugations for wires were purchased. We will not repeat old mistakes, we place powerful stepper motors on each axis. And most importantly – the project and the 3D model of the machine.

I will not answer the reader’s question whether the presented mechanics will withstand the load when milling the material, because it has not come to fruition. By that time, affordable 3D printers began to appear, people began to place ads for printing, which means that the need for prototype cases, gears, stands and other intricate figures was satisfied. And I sold the spindle with nozzles and chastotnik, almost for the same money that I bought. The buyer arrived in a minibus, a bearded man in glasses with glowing eyes, it was immediately obvious that he had a good idea.

air hockey

Fortunately, there are those few who bring what they started to the end. My good friend Sergey decided to make air hockey. He bought a sheet of laminate flooring, fans, pine timber, and other supplies, and within a week he assembled a great table. To my knowledge, drilling 2,000 holes across the table is one of the most fun parts of the manufacturing process. But the efforts were not in vain, and Seryoga and I sat up until midnight, enthusiastically playing air hockey, until, finally, his wife dispersed us.

The product had one drawback – the account must either be written down or memorized. Both that and another do not stick well with the amount of alcohol consumed, some rounds had to be reset, the game had to be restarted. In addition, there are controversial points, according to the rules, the cue ball should not cross the middle line of the table. In the most intense series, the dynamics of the game rolls over, the mind is completely focused on the game space, attacks and retaliatory strikes occur in a split second. So there is no time left for scoring.

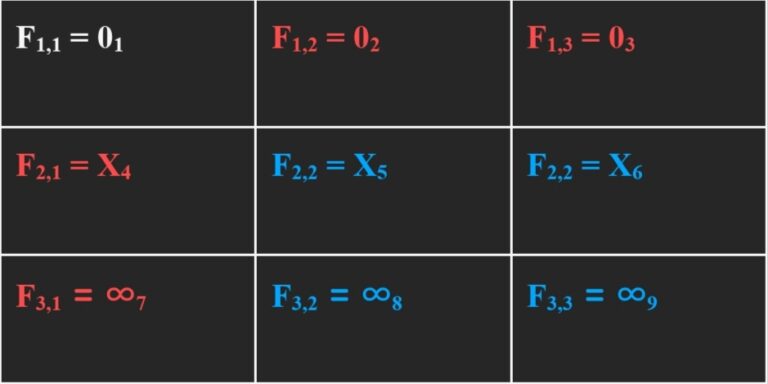

In my opinion, making an electronic air hockey counter for a friend is a good idea. The very next day, the first draft of the circuit appeared in Altium. Two seven-segment indicators, a 0.96-inch OLED display, three control buttons, a battery and a charge circuit, plus a radio module based on the Si4432 chip – that’s what was included in the Tablo project. We mount lasers and IR receivers in the table, the intersection of the line gives a signal to the comparators located on a separate board. In the same place, the message is processed, which is transmitted to the scoreboard via a radio channel.

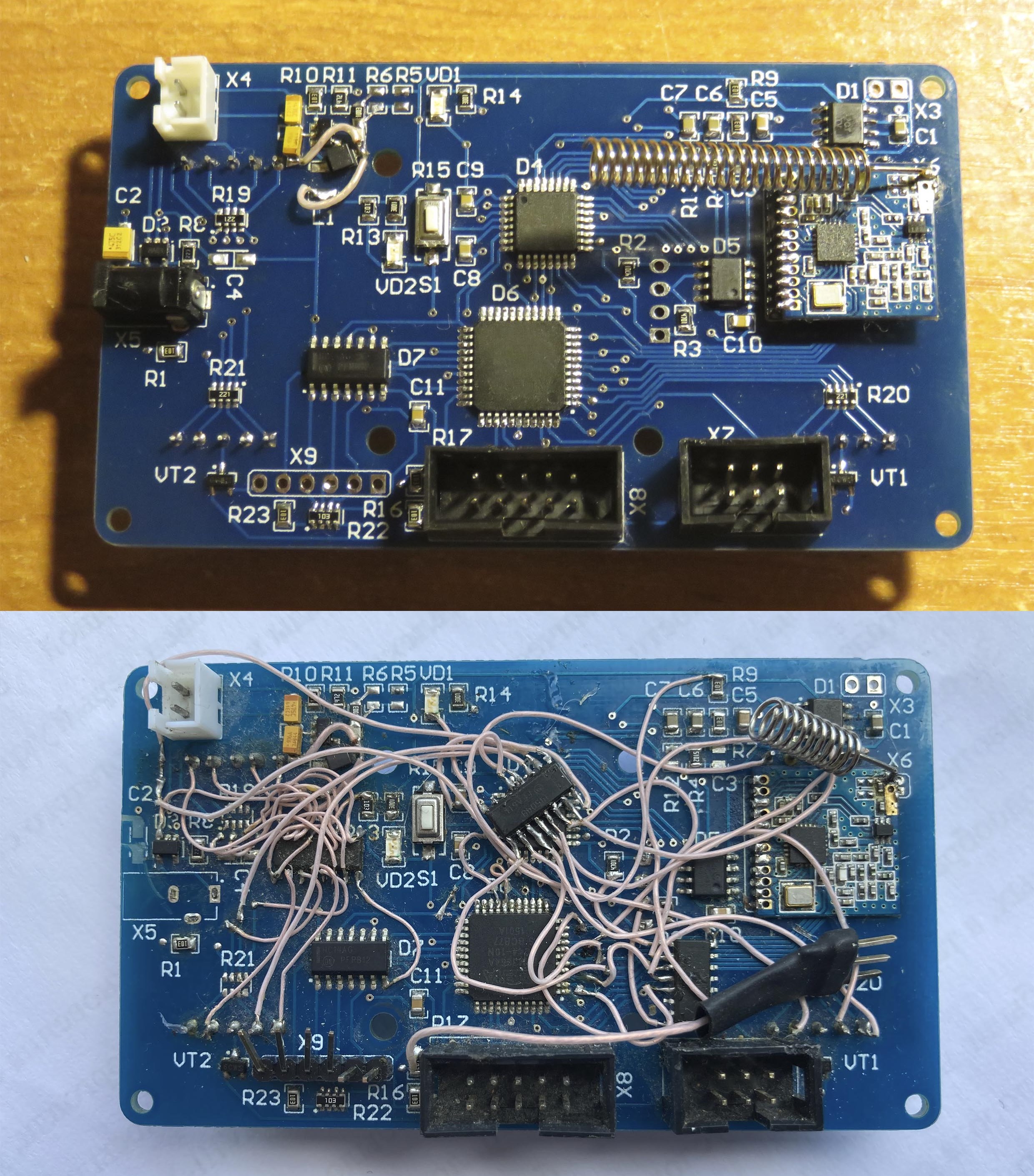

And then came the problems. Errors in the tracing of the DC / DC converter, the issue of power consumption, difficulties in adjusting the laser-receiver pair, confusing program logic. And the fattest blot: the power supply of seven-segment indicators through the EPM3064ATC44-10N plis with a supply voltage of 3.3 V, at which they barely glow. A serial code converter is built on the plis, the bill is simply sent to the SPI port. Not the most reasonable solution in terms of price, and common sense, but in the subject of publication.

We bring the product with the help of level converters and wiring to a functioning prototype. Then we are convinced that the scheme is unstable, we are faced with the difficulties of radio channel communication, which we could not launch at all, and more urgent matters appear in life. And so the next development moves to the freezer.

Under the case, it was originally planned to use a purchased square box. Cheap and affordable, but not pretty. We are surrounded by a lot of things with a rather banal design, handmade one-off products must be attractive. A couple of years later, equipment for testing radio modules appeared at hand, some knowledge. As it turned out, the antenna on the modules practically did not radiate, it was necessary to adjust the carrier frequency, the modules simply did not hear each other. The scoreboard made a second leap to life.

The design of the case is still pretty to me, a round weighty piece of iron, aluminum edges on the sides resemble a washer, the metal buttons are chosen quite well. It’s funny that the edges were machined to order by a person who did not abandon the idea of \u200b\u200ba home-made CNC machine. I came to Gennady’s garage for an order, contemplated his brainchild with delight. A massive frame, powerful engines, high-quality plain bearings, in general, everything that was not in my product.

But time has been lost. There was no longer any special desire to debug the scoreboard, tinkering with wires is troublesome, and ordering a new board without proper debugging of the prototype is pointless. In addition, Sergey acquired a simple score counter, similar to mechanical account, and subsequently completely moved the table to the garage. Such is the wisdom of Solomon’s ring.

Bibliography

The two projects described are not the only failed attempts to bring a good idea to life, and they can hardly be called large-scale. I am sure that such initiatives arise daily in the minds of millions of people on the planet and they fizzle out with the same frequency. Failures are not fun to share. Involuntarily, Nassim Taleb and his “Black Swan” come to mind. How many success stories do we know and how many failure stories? Who cares to know that the bridge was not completed, that the plane did not fly in, or the motherboard burned out. Although the “epic” failures still become public, sometimes attractions. Space shuttle “Buran” or aircraft carrier “Ulyanovsk”; the city of Xiangyun in China or the Arena da Amazonia stadium in Brazil; mobile phones Kin One and Galaxy Note 7 are widely known examples of unfulfilled hopes.

So how do you know if an idea is good? A multifactorial equation that takes into account the individual, his capabilities, time, society and the idea itself. It turns out the Babylonian library of Daniel Dennett, a sort of design space. Lots of solutions, good and bad. A constant search is needed with his Intuition Pumps. Other authors, such as Edwards Deming, believe that you should think more about quality, financial success will come by itself. But not all quality products occupy a niche in the market. In his book Interface: New Directions in Computer System Design, Jeff Raskin talks about what I think are very successful concepts. The shared workspace of documents, interactive interactions between applications, loci of attention, habits, time intervals, and number of operations all need to be considered to improve the quality of human-computer interaction. Nevertheless, Canon Cat has not received proper distribution.

In his book Think Slow, Decide Fast, Daniel Kahneman introduces the idea of mental abacus. The bottom line is that having invested in any direction, it is hard for a person to quit everything, even if it is pointless to continue. The brain clings to an accustomed little thing or idea, its value for the individual becomes higher than the market price. The book is replete with examples of irrationality and logical failures. Once again it is proved that we often behave inconsistently and illogically.

![[Паттерны API] Asynchrony and time management](https://prog.world/wp-content/uploads/2023/05/ffda31052ac72f457031cc6fbadb3c40-768x403.png)