Why are scientists creating a transparent tree?

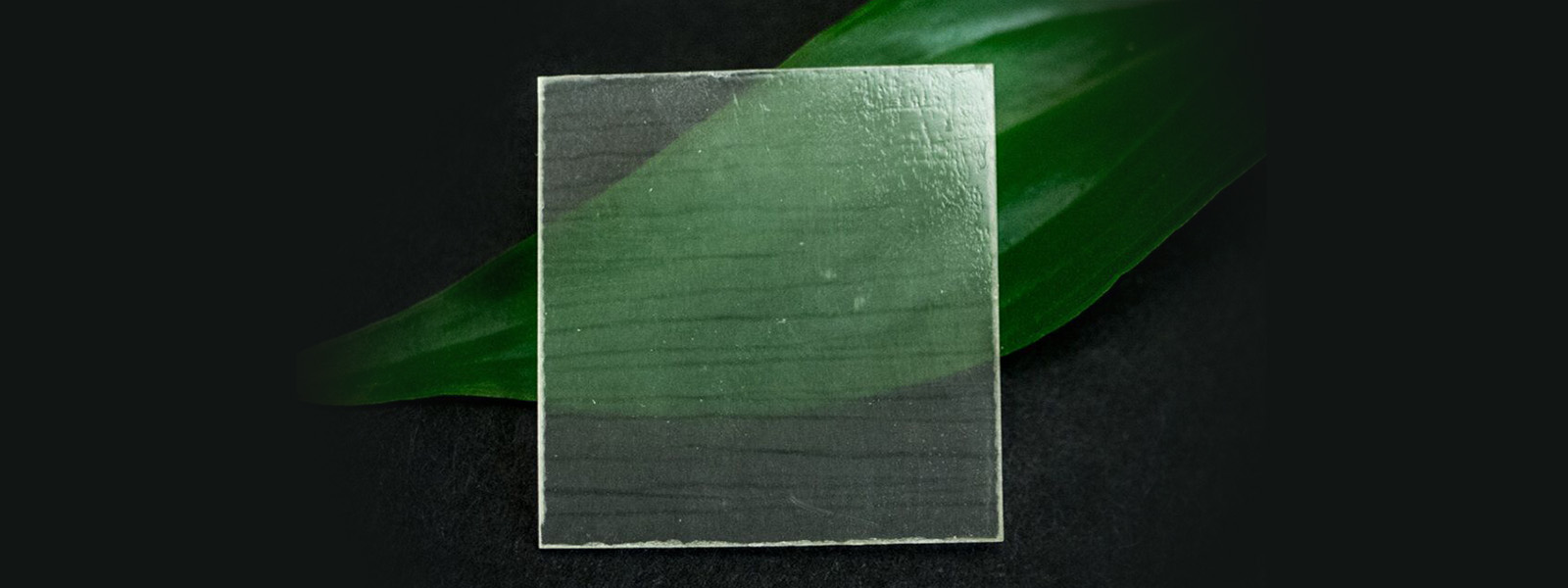

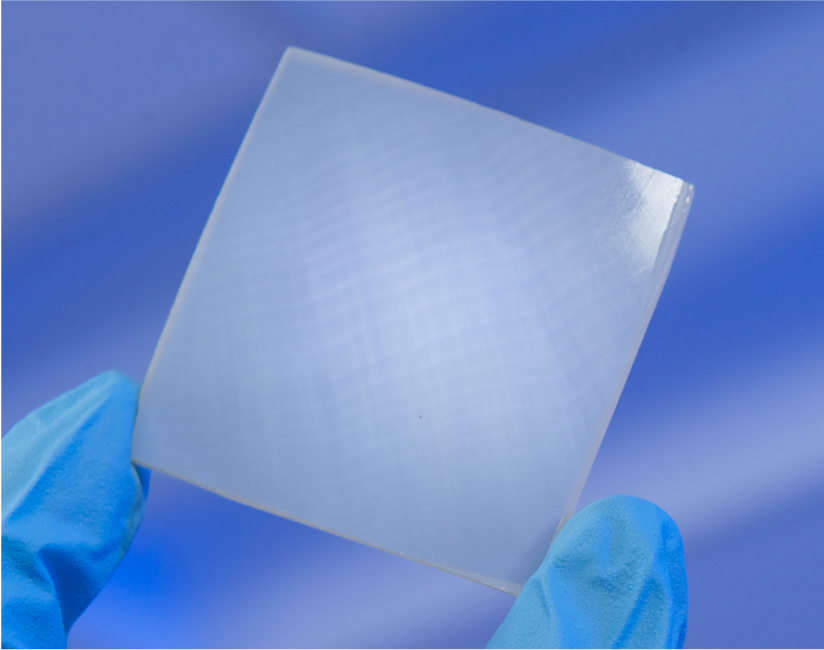

Stronger than plastic and tougher than glass, the resin-infused material is used to make smartphone screens, sealed windows and more.

Thirty years ago, a botanist from Germany had a dream: to see the inner workings of plants without dissecting them. By bleaching pigments in plant cells, Siegfried Fink was able to create transparent wood and published his technique in a niche journal on wood technology. The 1992 paper remained the last word on transparent wood for more than a decade, until a researcher named Lars Berglund stumbled upon it.

Berglund was inspired by Fink’s discovery, but not for botanical reasons. The materials scientist, who works at the Royal Institute of Technology KTH in Sweden, specializes in polymer composites and was interested in creating a more durable alternative to transparent plastic. And he was not the only one interested in the virtues of wood. Across the ocean, researchers at the University of Maryland were busy with another goal: harnessing the strength of wood for unconventional purposes.

Now, after several years of experimentation, the research of these groups is beginning to bear fruit. Transparent wood could soon find its way into heavy-duty smartphone screens, soft, glowing lights, and even construction applications like color-changing windows.

“I truly believe that this material has a promising future,” says Qiliang Fu, a wood nanotechnologist at Nanjing Forestry University in China who worked in Berglund’s lab as a graduate student.

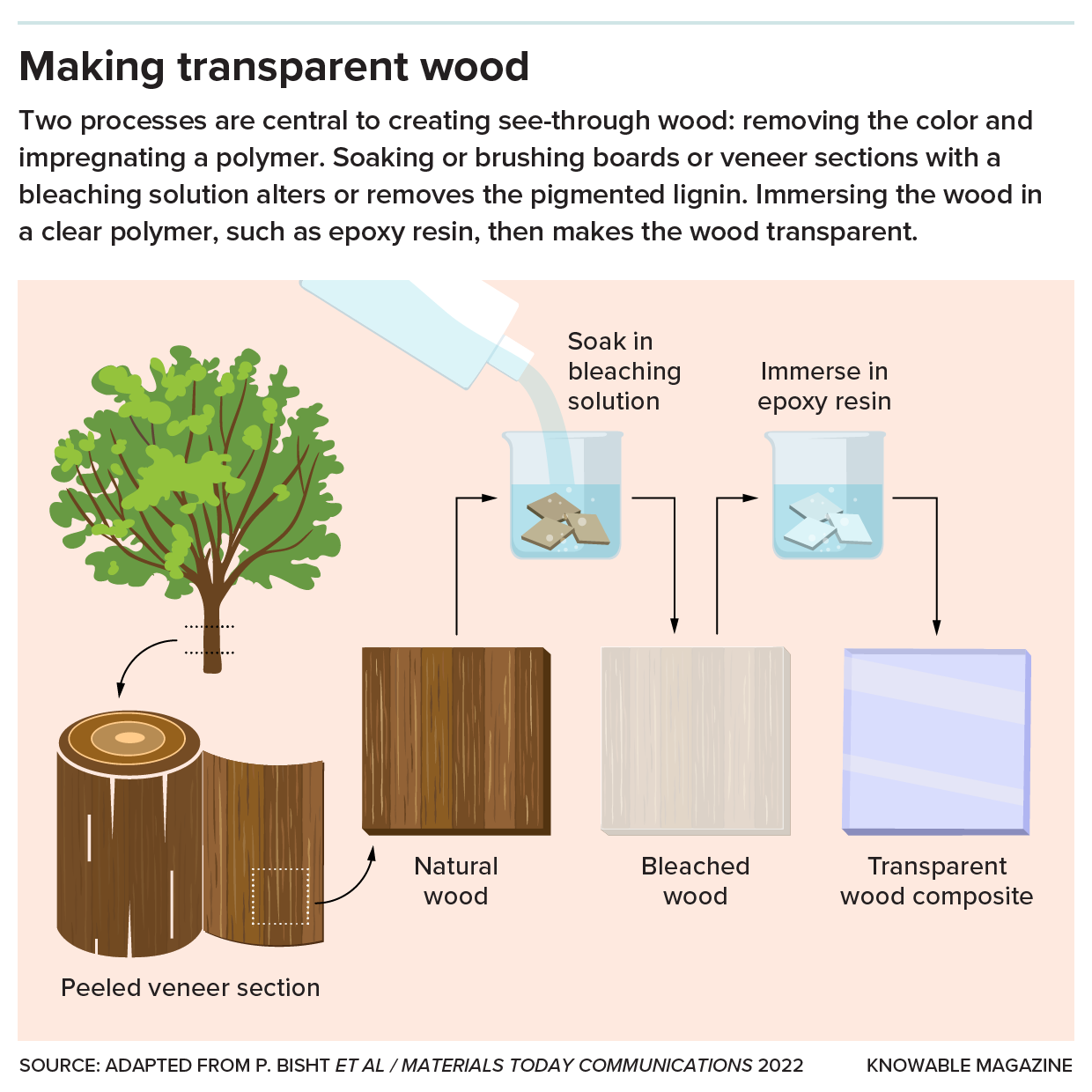

The wood consists of countless small vertical channels, like a tight bundle of straws, held together with glue. These tubular cells transport water and nutrients throughout the tree, and when the tree is cut down and the moisture evaporates, air pockets are left in these areas. To create transparent wood, scientists first need to alter or eliminate the glue, lignin, that holds bundles of cells together and gives trunks and branches much of their earthy brown hue. After bleaching or otherwise removing the color of the lignin, a milky white skeleton of hollow cells remains.

This framework remains opaque because the cell walls refract light differently than the air in the cell pockets – they have a different refractive index. If you fill the air pockets with a substance like epoxy resin with a similar refractive index to cell walls, the wood will become transparent.

The material the scientists worked with is very thin – usually its thickness ranges from a millimeter to a centimeter. But the cells create a strong honeycomb structure, and the tiny wood fibers are stronger than the best carbon fibers, says materials scientist Liangbing Hu, who leads a research group working on transparent wood at the University of Maryland, College Park. And with the addition of resin, transparent wood is superior to plastic and glass in many respects. In tests measuring how easily materials break under pressure, clear wood was found to be three times stronger than clear plexiglass, and about 10 times stronger than glass.

“The results are amazing: a piece of wood can be as strong as glass,” says Hu, who told on the properties of clear wood in the 2023 Annual Review of Materials Research.

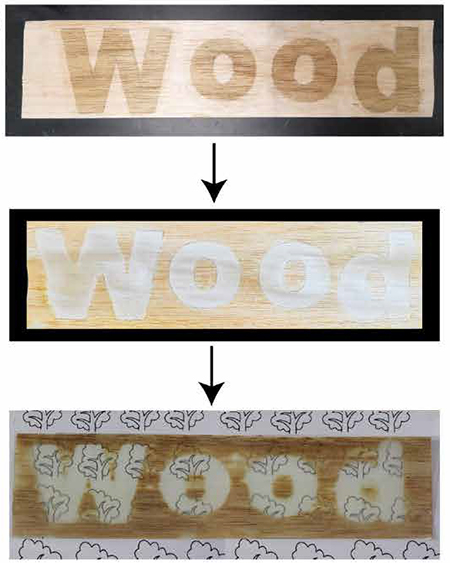

The process can also be used with thicker wood, but the view through it will be cloudier as it scatters more light. In their original research in 2016, Hu and Berglund found that millimeter sheets of resin-filled wood frames allowed 80 to 90% of light to pass through. As thickness approaches a centimeter, light transmittance drops: Berglund’s group reported that wood 3.7 mm thick allowed only 40% of the light to pass through.

The thin profile and strength of the material mean that it can be an excellent alternative to products made from thin, easily breakable plastic or glass – such as display screens. French company Woodoo, for example, uses a similar lignin removal process in its wood screens, but leaves some lignin behind to create an interesting shade of color. The company develops its recyclable, touch-sensitive digital displays for automobile dashboards and billboards.

But most research has focused on using transparent wood as an architectural element, with window applications showing particular promise, says Prodyut Dhar, a biochemical engineer at the Indian Institute of Technology Varanasi. Translucent wood is a much better insulator than glass, so it can help buildings retain heat or keep it out. Hu and his colleagues also used polyvinyl alcohol, a polymer used in adhesives and food packaging, to impregnate the wood frame, causing the transparent wood to conduct heat five times worse than glass. reported team in 2019 in the journal Advanced Functional Materials.

Researchers are developing other ways to improve wood’s ability to retain or release heat, which could be useful for energy-efficient buildings. Celine Montanari, a materials scientist at the Swedish research institute RISE, and her colleagues experimented with phase-exchange materials that, when changing from solid to liquid or vice versa, switch from holding to releasing heat. For example, by incorporating polyethylene glycol, scientists discovered that their wood could store heat when it was warm and release it when it cooled, the work was published in the journal ACS Applied Materials and Interfaces in 2019.

So, clear wood windows will be stronger and help regulate temperature better than traditional glass, but the view through them will be cloudy, more like frosted glass than a regular window. However, this haze can be an advantage if the user wants diffused light: Because thick wood is strong, it can be part of a supporting structure that conducts light, Berglund says—for example, a soffit that provides soft, diffused light into a room.

Hu and Berglund continue to look for ways to add new properties to transparent wood. About five years ago, Berglund and colleagues at KTH and Georgia Tech discovered that they could simulate smart windows that could switch from clear to tinted states to block visibility or sunlight. The researchers placed an electrochromic polymer—a substance that can change color when exposed to electricity—between layers of transparent wood coated with an electrode polymer to conduct electricity. As a result it worked out a wooden panel that changes color from clear to purple when a small electrical current is passed through it.

Recently, both groups have shifted their attention to making clear wood production more environmentally friendly. For example, the resin used to fill wooden scaffolding is typically a plastic derived from petroleum, so it’s best to avoid using it, Montanari says. As a replacement, she and her colleagues invented an entirely biological polymer derived from citrus peels. First they combined acrylic acid and limonene – Chemical substance, mined from the peels of lemons and oranges and contained in essential oils. They then impregnated the lignin-free wood with it. Even with fruit filling, the bio-based transparent wood retained its mechanical and optical properties, withstanding 30 megapascals more pressure than conventional wood and transmitting about 90% of light, the researchers reported in the journal 2021 in Advanced Science.

Hu’s laboratory, meanwhile, recently reported in the journal Science Advances about a greener lignin bleaching method that uses hydrogen peroxide and ultraviolet light, further reducing energy requirements during production. The team treated pieces of wood ranging from 0.5 to 3.5 mm thick with hydrogen peroxide and then left them in front of ultraviolet lamps that simulated the sun’s rays. Ultraviolet light bleached the pigment-containing parts of the lignin, but left the structural parts intact, which preserved the strength of the wood.

These greener approaches help limit the amount of toxic chemicals and fossil polymers used in production, but for now glass still has a lower environmental impact at the end of its life than clear wood, according to an analysis by Dhar and colleagues in the journal Science of the Total Environment. Adopting greener production patterns and scaling up production are two steps needed to bring transparent wood into mainstream markets, but it will take time, the researchers say. However, they are confident that it can be done and believe in its potential as a sustainable material.

“Trying to make manufacturing more sustainable requires more than just matching the properties of known materials made from fossils,” says Montanari. “As a scientist, I want to surpass their properties.”