Who is killing my clothing production?

DISCLAIMER: The article was written by the author of the blog based on an interview with the owner of a clothing production in the Moscow region, Evgeny Apachev.

For 11 years, my production has been sewing workwear for doctors and flight attendants, vests for unheated Wildberry warehouses, and other uniforms. 10 people on 150 sq.m in the Moscow region sew clothes worth 1.5 million per month. Today we are going through difficult times, like the entire industry, and here's why.

In the article I will tell you how I did not understand the language of kickbacks, why female alcoholism is terrible, how much you can earn when you dress a factory, and what problems await you in the clothing industry if you are not Coco Chanel.

But before moving on to the problems, I’ll briefly tell you about my production.

Sewing production from scratch

Sewing production is not my first business. My partner and I were doing electrical installation, and somehow our current customer’s contractor couldn’t cope with the supply of workwear. We saw this as a new opportunity and resold the batch of clothes. They made good money and decided that if they bought their own cars it would be even more profitable.

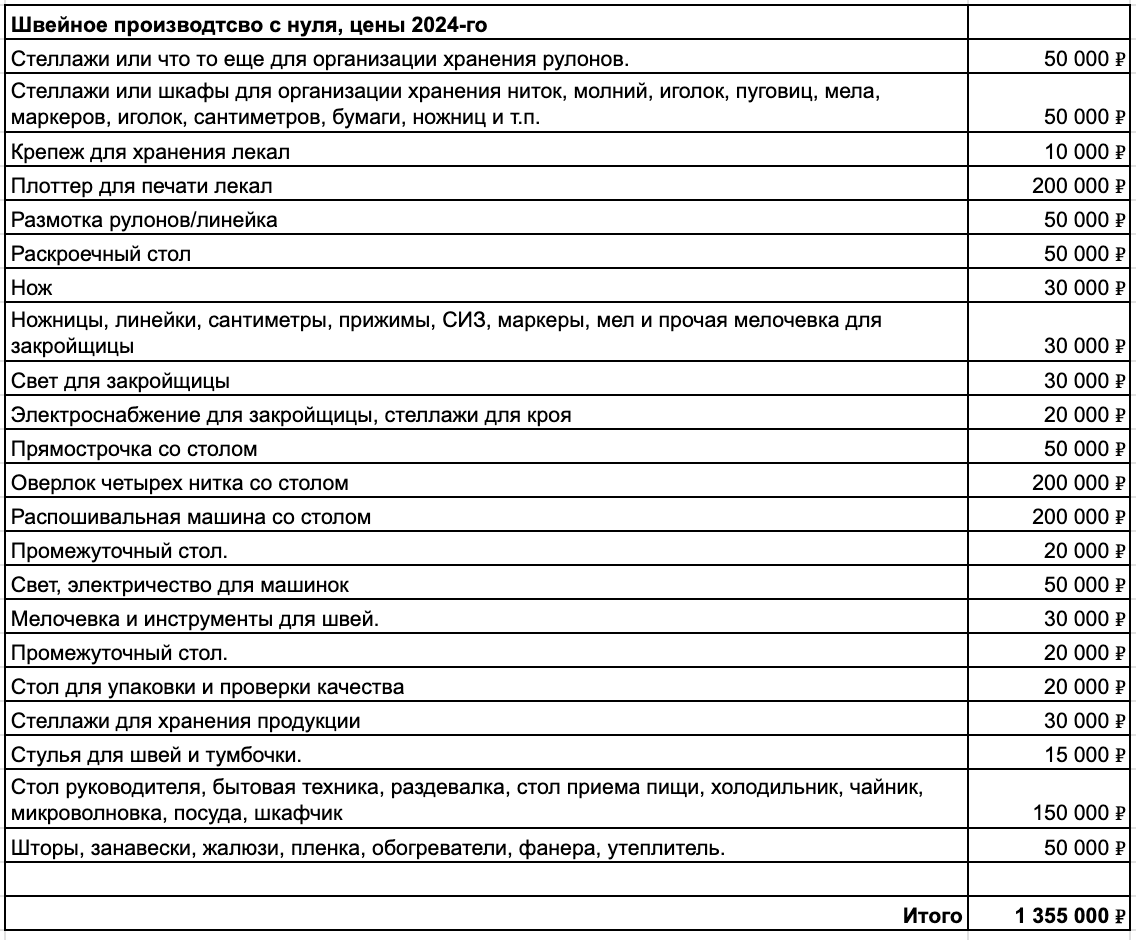

At the start of sewing production, you can get by with equipment worth 1.3 million rubles. There is a lot of equipment, because even to sew an ordinary sweatshirt you will need 3 machines. The straight stitch stitches, the cover stitch sews in the cuffs and collar, and the overlocker makes the side seams and sews the sleeve.

A complete list for starting your production can be found below.

But buying materials, renting a room and purchasing equipment is not the most difficult thing. If you are planning to open your own sewing production, the first thing you should think about is where to hire people. But more on that later.

Sales

At first, orders went well because everyone was interested in testing the new manufacturer.

Buyers

Usually our customer is a buyer. It’s not like in small companies where they simply tell someone: “Go ahead and buy something.” This is a separate specially trained person. He maintains a register of reliable suppliers and decides who to give the order to. And the main thing in this niche is to be familiar with buyers or office managers who are internal customers for the buyer.

In the procurement of large companies, everything is very conservative; they are not prone to sudden changes. It’s on WB that we look and: “Oh, I’ll take it!” Buyers try to work for years, because their task is to achieve the goal and if the company fulfills its obligations, then they will be extremely reluctant to change such a counterparty.

We may no longer work with the customer, but they still call us with requests:

– Do you make gloves? Can you sell it to us urgently? Otherwise we don’t have it.

– No, we don’t produce gloves.

– But maybe you know where to get it?

Kickbacks

Buyers build their own relationships and care that their work is done well to keep their internal customers happy. I almost never see any hints of kickbacks.

But here I need to make a reservation that I do not understand the language of kickbacks. Perhaps those who work this way simply see that I do not understand the required language and therefore do not come to me.

Perhaps I’m ignoring the phrase: “You know, I haven’t been able to buy myself a new car for 2 years…”. Perhaps the world actually works differently.

Government procurement

As soon as the criterion of the cheapest is the best appeared in government procurement, it became possible to sew from garbage and win the tender. Or put people in the basement, cheat on their salaries, kick them out, and therefore win the tender and somehow make money from it.

There are adventurers who win tenders without sewing production, and then run around the market and try to sell. They come running to me and say:

– Will you sew a medical jacket for 650 rubles along with the fabric?

– But it’s impossible to sew it for 650. We won’t sew it, goodbye.

There have been stories where there are 3 intermediaries before the tender, and in the end the poor people in production can’t cope and work at a loss.

Advertising

We advertise in Yandex.Direct and on maps, request “working clothes to order”.

Sometimes startups or designers come from there and want to make 500 flight suits for resale.

It’s not interesting to go to WB, because it’s impossible to compete with the guys who brought black clothes from China.

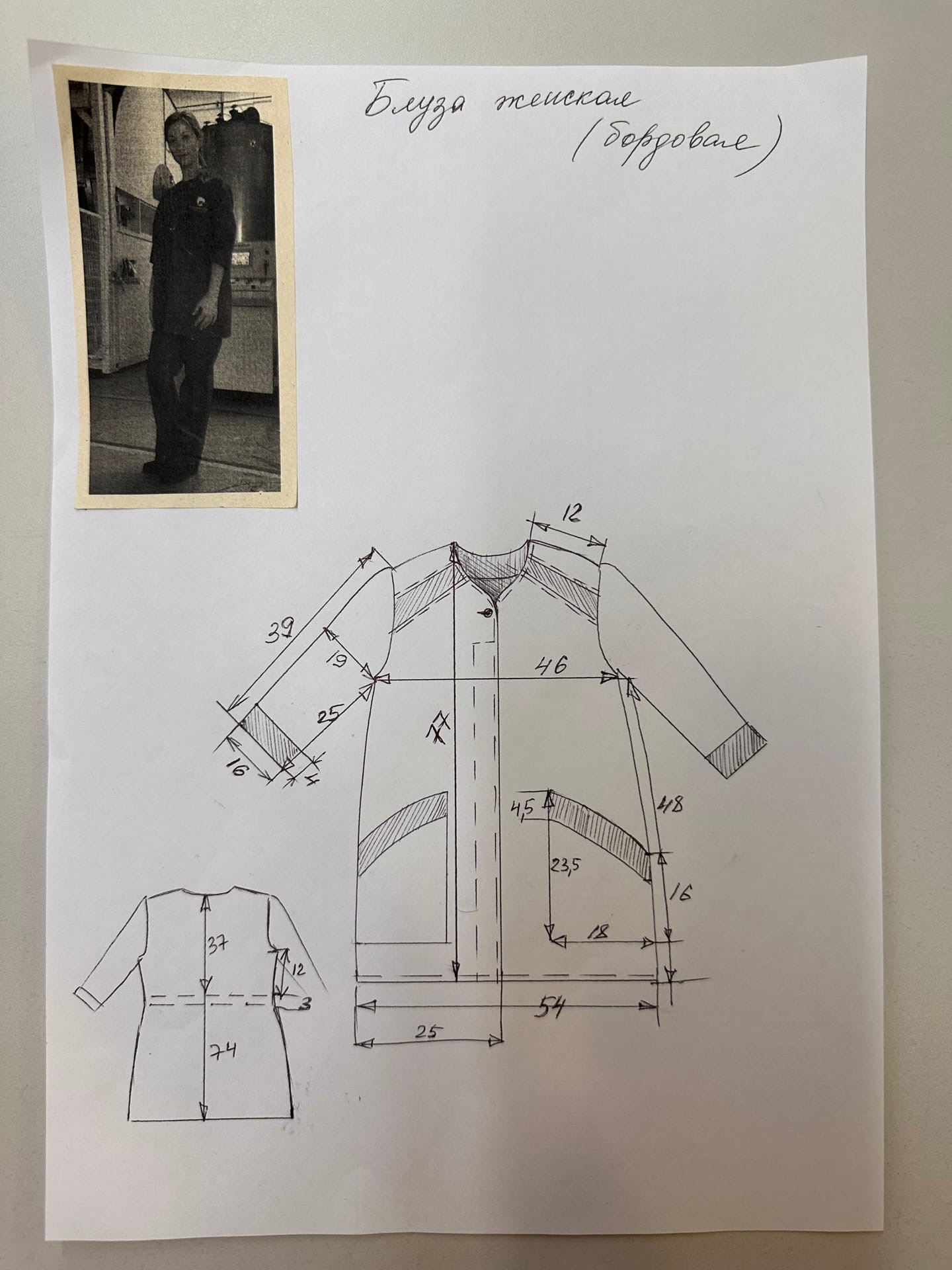

We sew many types of products. But the equipment was purchased carefully.

For example, a customer comes to us from advertising and needs 500 jeans. And to quickly sew jeans, you need two threads. This is a machine that sews two lines at once; if you do it on a single line, it will be crooked and long. If there was only one such order from advertising, we refused it, but if orders for a product that required new equipment came in periodically, we bought additional machines.

How much does 1 product cost?

A small sewing production requires developing an optimal sewing pattern every time.

Finding those who organize the process is much easier than a seamstress who will work back and forth with her hands 8 hours 5 days a week.

If we are sewing a product that involves a lot of operations, then the seamstress makes the entire product because there are not enough people. If there are 2-3 operations, then we try to organize a conveyor.

We sew things that you can't buy in a store. On WB you can buy a medical jacket for 600 ₽, made in China from some kind of fabric, I don’t want to say bad things.

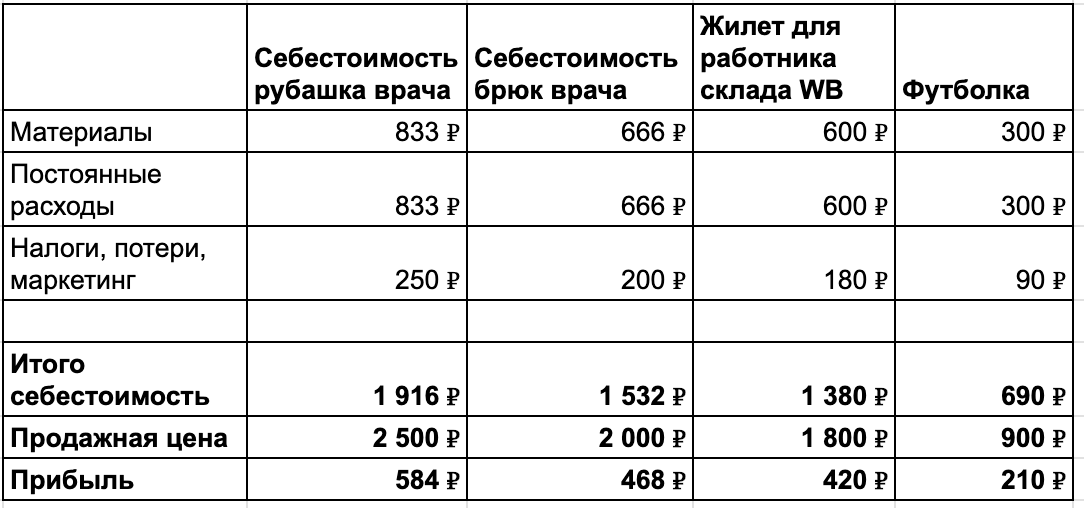

Typically, the cost of our products looks like this:

But the amount of fixed costs per unit of product will greatly depend on the number of products produced as a whole. And it depends on how many orders you receive.

If there are a lot of orders, then the cost is lower, but if there are few orders, then the company will easily operate at a loss, and this happens regularly.

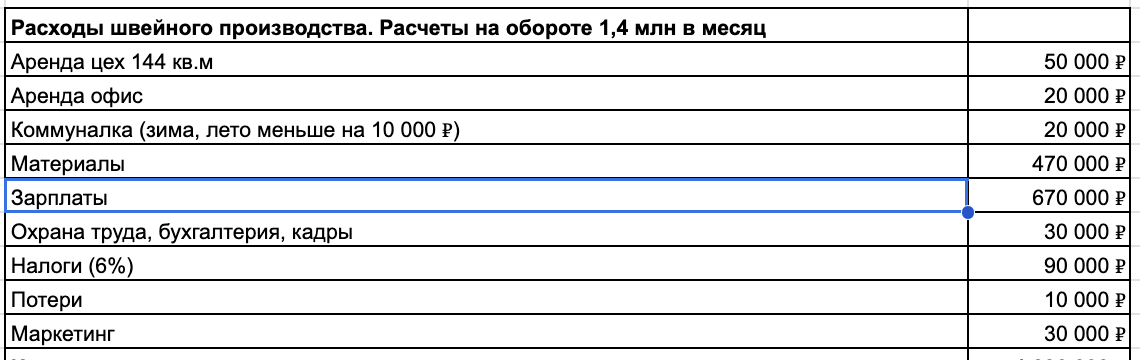

Clothing production costs

Rent – 70,000 ₽

Now the competition for seamstresses is such that some sewing factories are opening in shopping centers. Beautiful rags hang outside, and inside there are seamstresses in slippers and sweatpants. Women often don't have cars, so location greatly influences whether they'll come to work for you. Even foreigners can only agree to work in basements for big money.

Salaries – 700,000 ₽

There are 2 ways to pay for work in the niche: transaction and salary. In our city, owners who sew themselves are very fond of this deal. They take interesting orders, call their girlfriends together with the call: “Girls, let’s sew!”, work hard for a month, earn 100k, then leave the next month.

And the second type is a plant, like ours. There is a salary, there is a bonus part.

Whether there is an order or not, no one cares anymore, people go to work on schedule, and I take the risks on myself. No one is interested in how I will manage further, the salary on the 1st and 15th without delays.

The master is the most experienced seamstress, she analyzes situations, finds out why this is so, and she monitors the quality.

The production employs 10 people. Packers earn the least (30k), then seamstresses (40k), then craftsmen and embroiderers, then cutters, then production managers. Personnel, labor protection and accounting are outsourced; their work is also included in the salary fund.

Losses – 10,000 ₽.

Usually marriage is an unintentional action, it is a lack of training and equipment. A person does not want to produce a defect. We have a rule: do not accept defects, do not produce defects, do not transfer defects. If there is a normal atmosphere in the team, and they are not fined for marriage, when the girls see that they have received a marriage, they do not pass it on. These rules are enough for us to get a minimum of defects in the box.

And the complete consumable looks like this:

How much can you earn in the clothing industry?

It is generally believed that a third of the selling price of a product is materials, another third is fixed costs, and the final third is taxes, waste, marketing and profit. But due to the described personnel problems, on our turnover of 1.5 million, 790k is spent on fixed expenses, instead of 500k. Therefore, per month, with our average turnover of 1.5 million per month, about 100-120k remain net. For two partners.

This is what the current financials look like. results:

And why? We need to answer the question in the title.

Problems of clothing production

Seamstress is a low-prestige profession

The biggest pain in the clothing industry is people. Out of 30 graduates of the sewing technical school, only 2 girls go to work as seamstresses. I helped one such technical school and when I said: “I have a vacancy!” Absolutely no one cared about this. Working as a seamstress in production is not prestigious. Girls go faster to get their nails done or get their eyelashes done.

Seamstress is a working profession. You spend 8 hours, 5 days a week moving back and forth.

This is mechanical, hard, very boring work. There is no creativity in this. Every day you repeat the same thing. I got my nails done, you can post a selfie in Ungram, what a wonderful person, in a beautiful outfit, beautiful nails, colors, like a beautiful life in a beautiful place.

A sewing enterprise is noisy, garbage, lunch on a schedule.

Work can be compared to harvesting. Is it difficult to pick carrots? Not difficult. He pulled it out, shook off the soil, and put it in a box. But it’s always in a pose, your back gets stiff, your brain is free, you need to carry out the plan.

Therefore, in conditions of personnel shortage, we are glad to have uneducated women who know at least a little sewing.

Dollar exchange rate

Everything depended on foreign labor. But with the change in the dollar exchange rate, the mathematics of living in Russia no longer converged for migrants. Now newcomers are asking for very noticeable salaries (70-80k to start with, but then they want more).

The struggle for personnel

We compete for personnel with:

– Pyaterochka and Wildberries. Where, like in our production, they pay a worker 40k.

– From Moscow. From Stupino to the capital – 100 km. In Moscow, seamstresses are paid 70-80k.

Female alcoholism

Given all the difficulties of working in the clothing industry, women drink. Those who earn little are subject to stress: they don’t have enough to buy a washing machine, but they don’t have enough to buy a bottle of beer.

People don’t show up for shifts, go on benders, drink at work, go out drunk, get coded, understand everything, want to come back, but they are already addicted. They say: “I’m done,” but they can’t work, not because they have a hangover, but because after binge drinking the nervous system can no longer cope and their hands are shaking.

You take a non-drinker, and she starts drinking. You already have a keen eye for drinkers, you just don’t hire them.

You talk to her: “So, what’s your next plan? Are you stopping? or you won’t be able to work here any longer.”

And it’s always difficult to leave, only training a new employee for 2-3 months, plus losses due to downtime.

We use everything we can to cope. If we can delay deadlines, we delay them; if we can ask employees to stay late, we ask. This is what a typical day looks like for a production manager: “Yes, Natasha is on a drinking binge, how are we going to solve this situation today?”

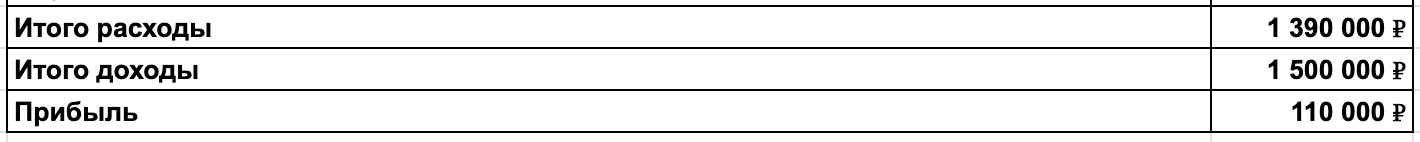

Marking

The clothing industry sews and sews, and then an agency appears that says: “Now you must buy codes from us for each product.” And for this you need to buy software, subscriptions, a label printer, and set everything up. We need to exist, so pay us.

The problem is not only one-time costs, the problem is that another business process appears inside the business. The code itself is inexpensive, but the system must be maintained, a seamstress cannot do this, and it seems as if a separate person must appear for this. A new area requires constant monitoring. The accountant is overloaded and will take on a new task only for another +5k to his salary. After all, these actions did not exist before, but now they have appeared.

The final

If I’m not complaining, we’re working and this month we’re buying a new sewing machine for 300k.

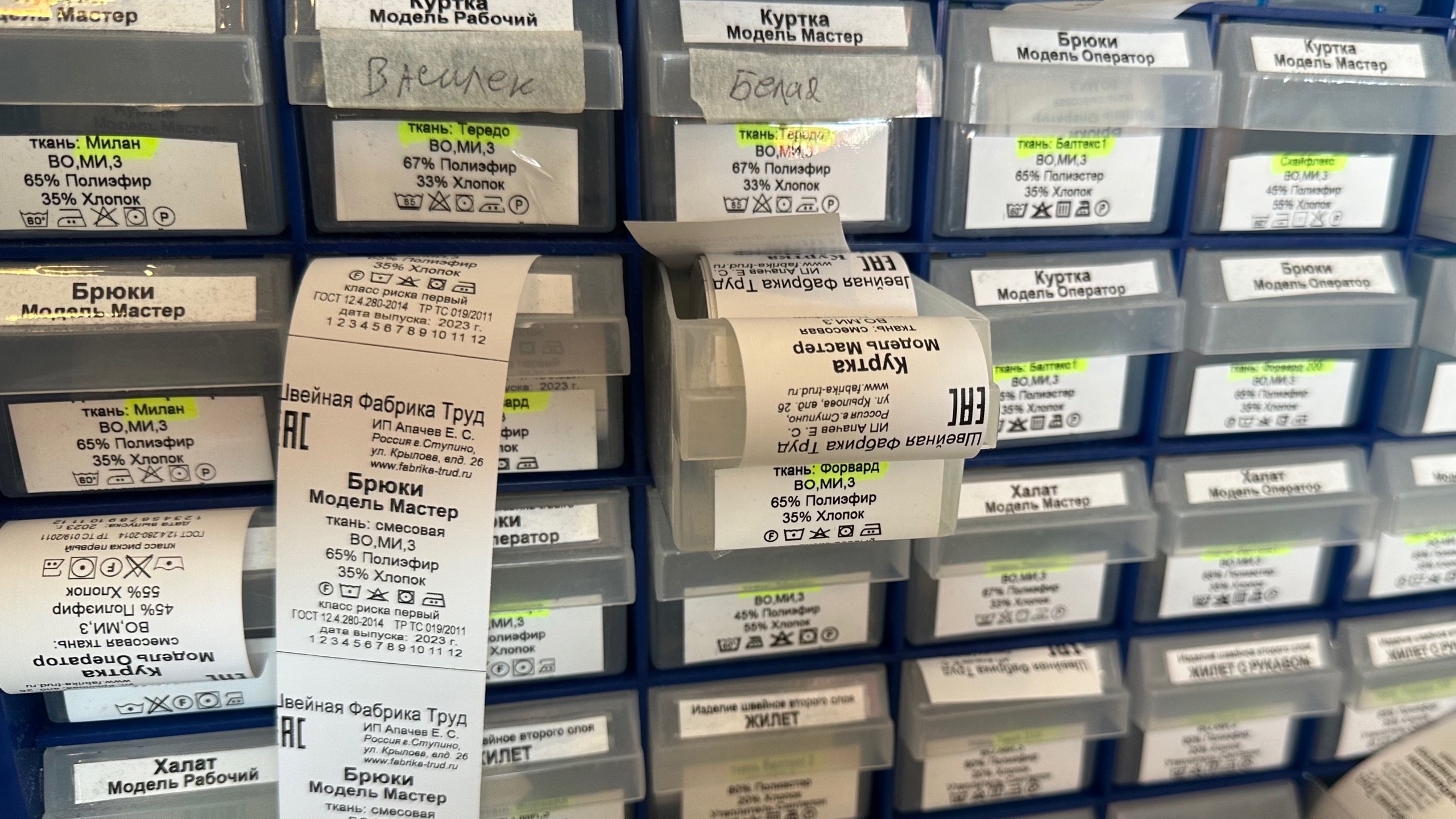

PS Sewing business plan for Steve Jobs' garage

In 2021, we were thinking about buying a share in a hosiery factory. And they calculated a business plan.

To knit a stocking or sock with or without a pattern, you only need one machine. She alternates the threads and gets a design.

Then another machine sews them up. Another machine and equipment helps with ironing and packaging. Everything is very simple. In Steve Jobs's supposed garage, all this will fit quite well and socks can be produced.

Captions

DISCLAIMER: The article was written by the author of the blog “fell, rose” based on an interview with the owner of a clothing production company, Evgeny Apachev.

I blog “fell, rose” with stories about real business, and not this successful success of yours.

You will read: how I opened and destroyed a chain of nightclubs, how to properly glue cardboard to sell it on marketplaces for 50 million a year, how a farmer spent 250 million in a village, why the production of dumplings in the province is dying, why there is a taxi fleet with 300 drivers and 40 cars are no longer a business, how a technician restored a Soviet camp, but flew into a cash gap of 60 million and other stories