LightCom monitors, bloggers and everything all everything…

Our previous publication about monitors is considered by many to be the beginning of a series of events that shook the Russian radio-electronics industry at the end of 2023. If anyone doesn’t know, after reading our article, blogger Maxim Gorshenin allegedly found a fraud when obtaining the status of domestic products for monitors from the Lightcom company. And although this is not at all true, since the story began much earlier than even our article. And the most important thing is now in its climax, and the denouement of this series will be enchanting. Well, we decided to spoil the plot of the next episodes a little.

But first, let’s tell you who we are and what we do. We are a very small analytical department in one very large implementation company. Our main task is to assess risks and verify the parameters of future contracts. So we are more lawyers than techies. But at the same time, we distinguish Volts from Watts, and for particularly complex questions we know who to ask. And so, at the beginning of 2023, our company planned to participate in one large tender for the supply of equipment to one institution. For the planned tender, product items from various suppliers were selected, which had to be purchased in advance so that if we won the tender, we would be able to complete it within the specified time frame. Among the many positions were the notorious monitors. Since the tender was quite large, pre-emptive procurement was quite risky and management was tasked with not screwing up the selection. Therefore, we asked/bought/found most of the items planned for purchase from several suppliers for analysis/analysis in order to minimize risks and eliminate outright falsities. And based on the results of the analysis, we recommended supplier options and product items, which were approved and purchased. Usually, based on our recommendations, we do not receive verbal feedback from management, so sometimes we publish our information in specialized conferences. This allows us to post publicly the suppliers we have found, as well as get feedback from unbiased people.

But after the publication of Gorshenin’s first video about monitors in September 2023, we finally received 100 decibel feedback from the boss. And although even our top leaders were sure that the ears of one rejected supplier were sticking out in this story, the situation was aggravated by the fact that the tender was held, the contract was concluded, the products were delivered to the customer, but the closing documents had not yet been signed. And our customer really wants to turn all the stuffing back. And in this case, we end up not only with money for pre-purchased products, but also with fines under the contract. Therefore, the management gave us a new task to figure everything out, reassure the customer if possible and point out the culprits. Which is exactly what we started doing…

As a result, now we probably know everything about monitors. And of course, we found out why the Lykomov monitor has a microcontroller from Milandra. They told us everything. Unlike bloggers, we do not take money for publications, but it seems like in our case it’s the other way around – we paid. In addition, some of the actors in this performance began to openly screw up on stage, so that the audience got bored and began to leave the hall. So, let's go.

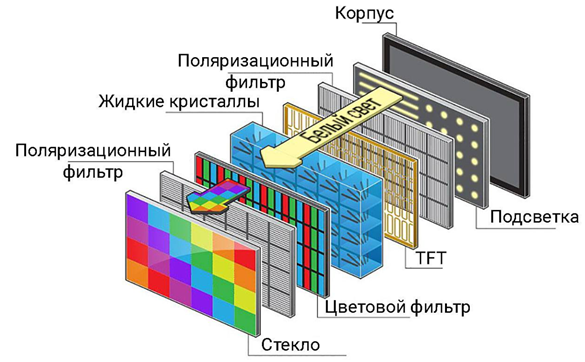

What does the monitor consist of and for what are points given in the register of the Ministry of Industry and Trade.

And so, according to government decree No. 719, when calculating points for monitors (OKPD2 code 26.20.17), various parameters are taken into account. There are mandatory requirements for the applicant – he must be a Russian company, the monitor must have been developed, he must have production capabilities, service centers, and so on – for this they give 20 points. Next come the formally optional requirements, but you need to get up to 90 points to get on the register (up to 24, 65 was enough). So, for making all the body parts (numbers 1,2,14,15 on the diagram) you can get up to 20 points. If some of the body parts are not Russian, then the points are reduced in proportion to the number of such parts. Another 10 points are awarded for assembling and testing the assembled monitor. Another 10 points for using domestic power supplies (number 12 on the diagram). You can also get 10 points for using domestic batteries (why are they in the monitor?). But, for example, for some reason they don’t give points for a domestic LCD matrix (numbers 3,4,5,6,7,8,9 on the diagram). Another 5 points are given for cables, again if some of them are not domestic, then the points are reduced in proportion to their number. Well, and most importantly, for using the domestic main controller board they give as many points as this controller board itself scored as a separate electronic module. Usually it is from 60 and above. Therefore, most manufacturers receive 20 points for mandatory requirements, 10 points for assembly and testing, and 60 points for domestic board. The total is the minimum required 90 points for inclusion in the register.

How many and how do monitor controller boards score (OKPD2 code 26.12.1 or 26.20.3). Just like for monitors, there are the same mandatory requirements for the applicant himself, for which they give 10 points. 70 points if the board is assembled in Russia and the printed circuit board itself is made in Russia. If the printed circuit board was made in China, and all the elements were just soldered in Russia, then for this they give not 70, but 40 points. Another 5 points will be given for writing the software onto the board. Another 5 points for testing. If domestic microcontrollers are used on this board, then 30 points are given for this. If there are several microcontrollers, and some of them are Russian and some are not, then the points are divided in proportion to their number. If domestic microprocessors are used, then you can get up to 50 points for them. When using any other domestic electronic component base, you can get up to 20 more points, where the number of domestic microcircuits is also divided by the total number of all microcircuits according to the product specification. As a result, manufacturers typically receive 10 points for mandatory requirements, 40 points for soldering chips onto a Chinese PCB, 5 points for testing, and 5 points for downloading software. In total, such boards score 60 points required for monitors.

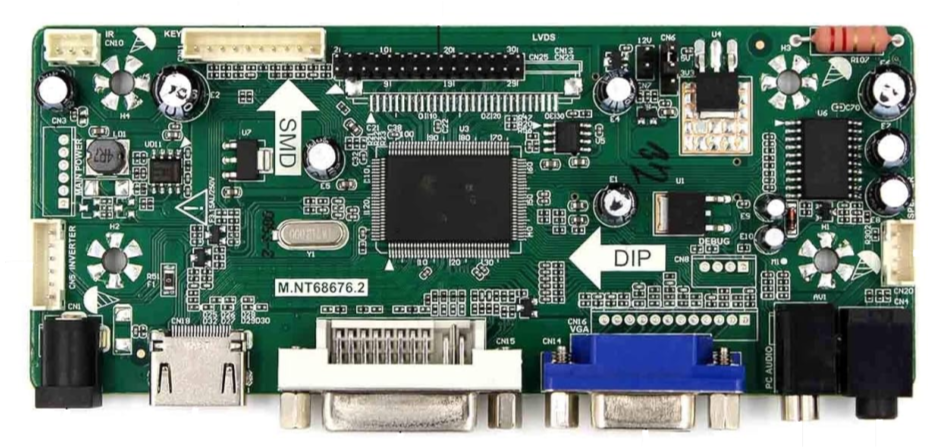

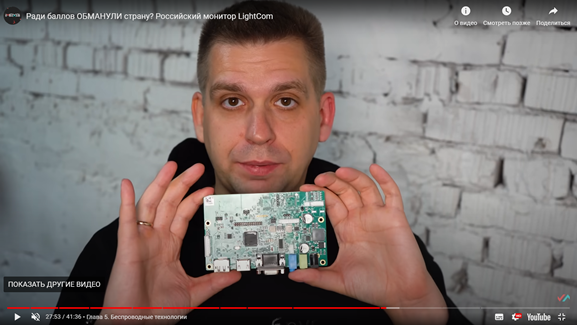

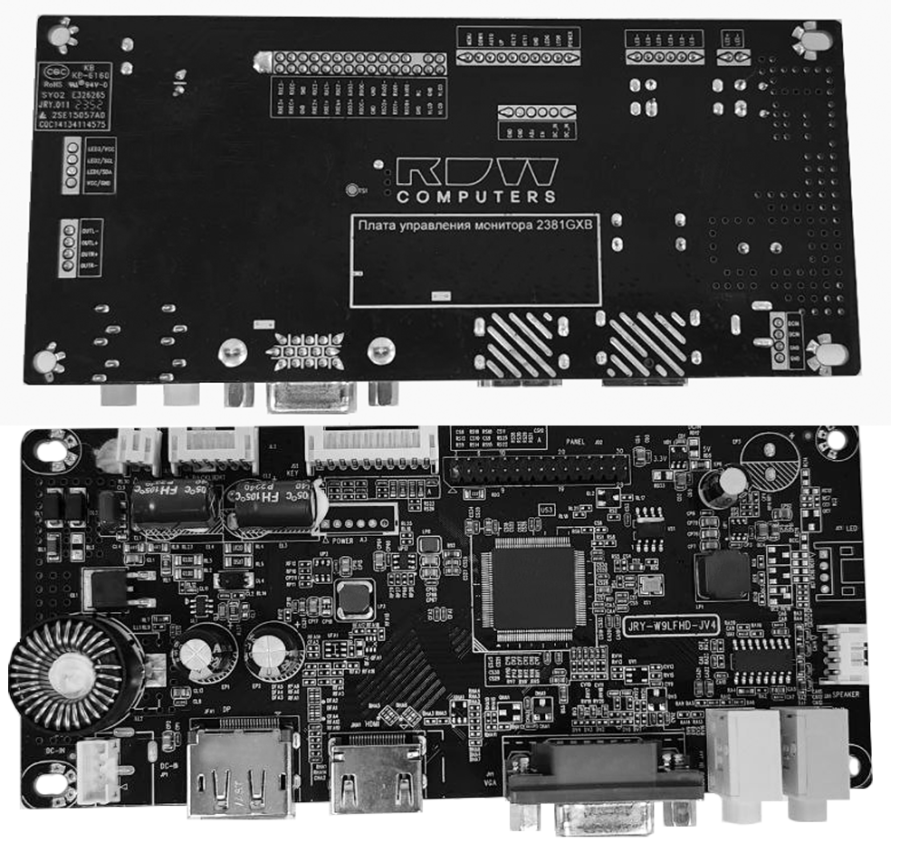

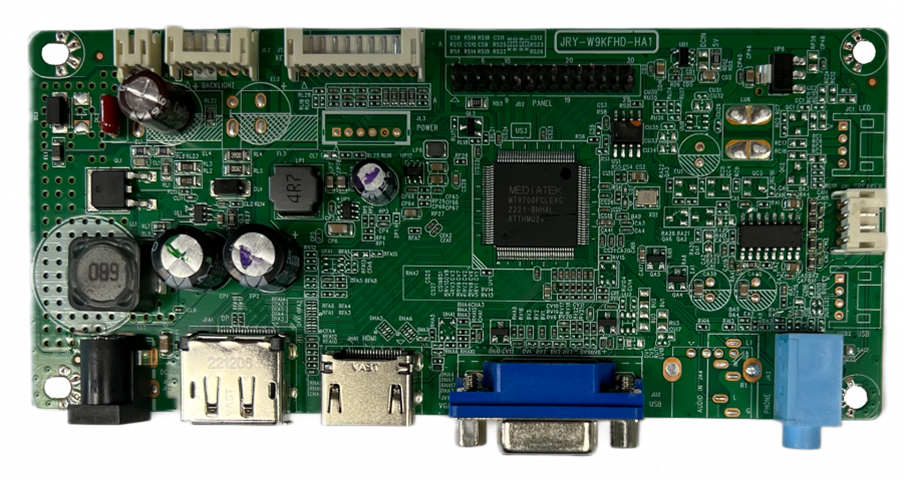

Below is an example of a typical board.

So now we know what points are given for. And to get into the register, as we see, it is enough to solder foreign microcircuits onto a Chinese printed circuit board, upload the software and assemble the monitor. And there is no need to use a domestic microcontroller or anything else just for the sake of inclusion in the registry. Even if manufacturers exceed the minimum threshold in terms of points (they make a housing, use domestic electronic components or cable assemblies), it is only because of some of their own business interests. We'll talk about this later.

What's wrong with bloggers' reviews?

Let's return to the videos about Lightcom monitors, or rather, in this case, let's talk about the video https://www.youtube.com/watch?v=aSYh_VLpWlQ from Alexey Violin (CEO of the International Association of Service Centers), which he recorded as an independent expert in support of Maxim, positioning himself as a specialist who understands all technical features.

Usually, when in a car service center we hear a mechanic scolding the car's design engineers for the inconvenient location of the oil filter, we treat it condescendingly. It seems like maintainability is one of the qualities of a car. But at the same time, we still understand that the engineers who develop cars have a slightly higher level of knowledge, compensation and education than a mechanic in a garage. And the layout decisions they make are more verified and always have a justification. If the service begins to lie to the client, saying: “Look, the brake disc is rusty, you need to change the entire caliper assembly… you don't joke with brakes…” At a minimum, the service needs to be changed.

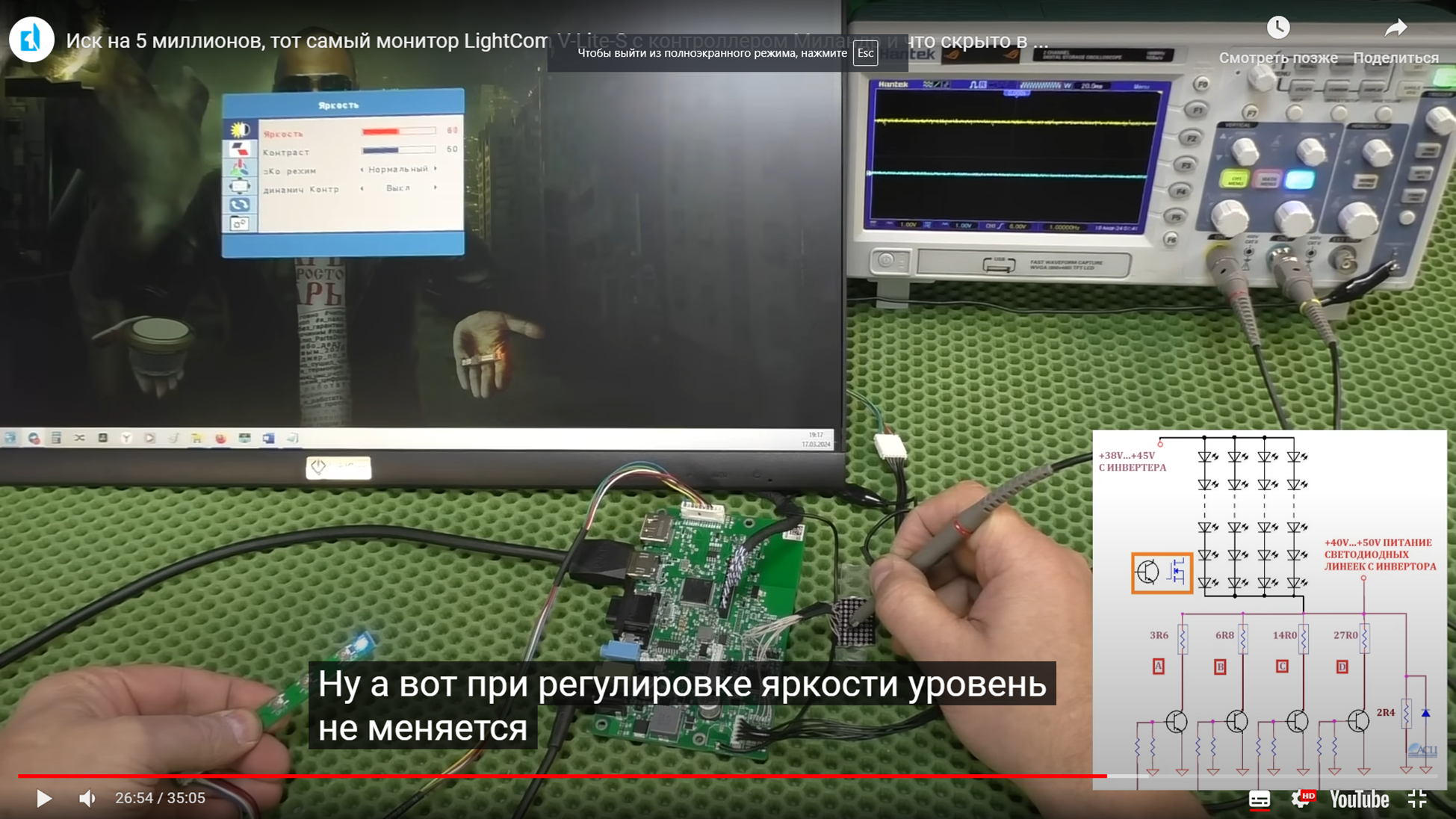

What did Violin do? He devoted the main part of his video to analyzing the part of the Lightcom controller board circuit that is responsible for generating the matrix backlight. In his opinion, the Milan microcontroller that controls the backlight should, if the brightness in the monitor menu changes, change the brightness of the backlight. And since nothing switches there, then the microcontroller is useless.

Well, first of all, let’s explain to the “big” monitor specialist Violin, and at the same time to all readers, how it really works. The brightness adjusted in the monitor menu and the brightness set by the matrix backlight current are completely different entities. The information displayed on the monitor is transmitted in RGB format from the video card (for example, via an HDMI cable) to the monitor matrix controller, where it is converted into control signals to the LCD matrix itself, which determine the color for each pixel. And if we talk about brightness, then brightness is calculated using the following formula:

Brightness = SQRT(R20.241+G20.691+B20.068).

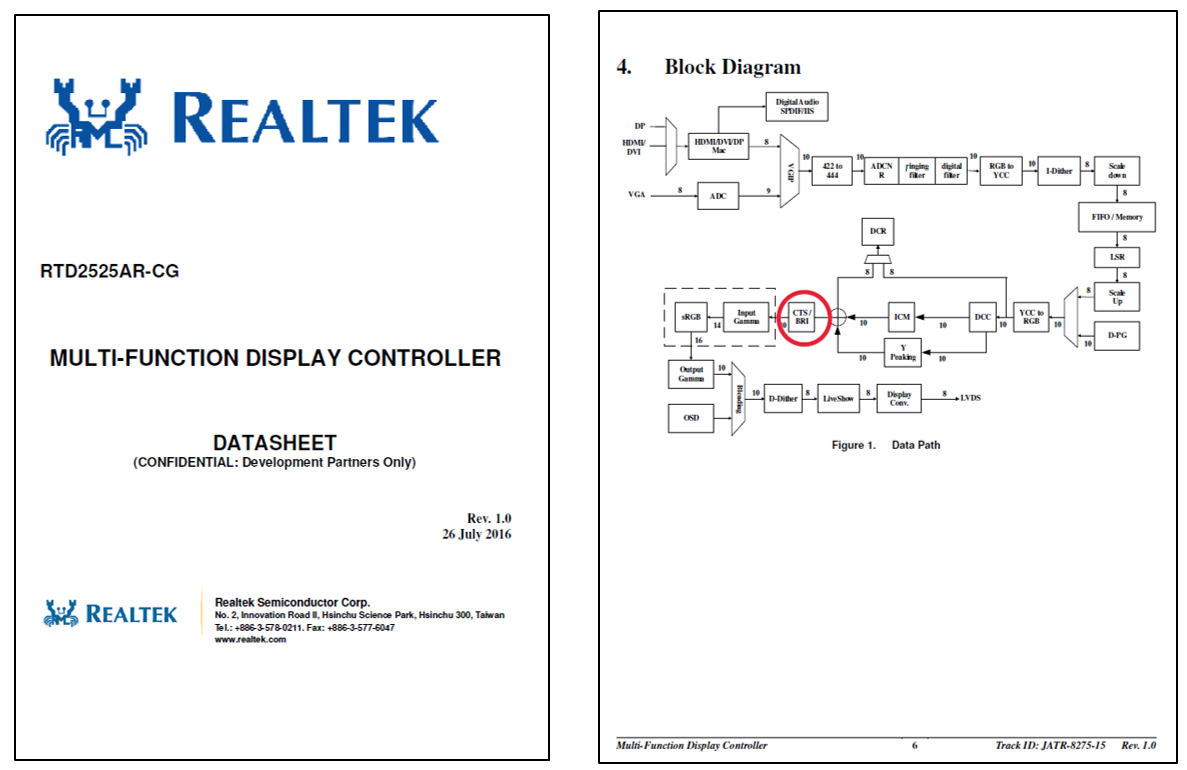

According to this formula, the green component makes the greatest contribution to brightness, then red and very slightly blue. Thus, to increase the brightness of a pixel, while maintaining the resulting color, you need to multiply the value of each of the RGB components by its own brightness change factor, which is proportional to its contribution to the overall brightness. This multiplication can be done with equal success, for example, in the settings of a video player program on a computer, in the settings of a video card, as well as in the monitor menu. If you change the brightness in the monitor menu, then in the RTD2525AR chip of the LCD matrix controller the CTS/BRI block for calculating contrast and brightness is responsible for this (screenshot from the specification of the RTD2525AR chip provided by Lightcom):

That is, depending on the selected brightness level in the menu in the CTS/BRI block in the RTD2525AR chip, the original RGB components of each pixel from the video stream are multiplied by the corresponding coefficients before being output to the matrix, where, depending on the received RGB code, the transparency of the liquid crystals changes.

And this does not affect the brightness of the screen backlight in any way. The matrix backlight is formed in a deeper layer of the matrix, and most importantly, it is always constant when the monitor is operating. White backlight light from powerful white LEDs passes through transparent or not very transparent liquid crystals, depending on the code set by the controller. And then through a color filter it turns into the color picture on the screen that we are familiar with. Thus, setting the brightness in the menu determines the brightness through the transparency of the matrix crystals, and the backlight brightness determines the brightness of the original white color of the rear layer of the matrix and is always constant. It’s strange that such a big specialist in monitors does not know these basic things. But rather, on the contrary, taking advantage of the fact that the average person does not know this, he deliberately misleads for a purpose that is obvious to us.

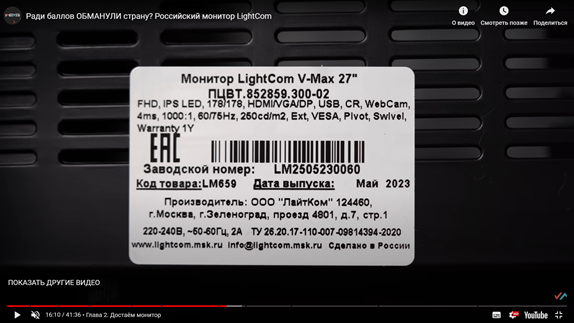

Why then do you need to adjust the matrix backlight current and why is there a microcontroller here? But first, let's go back to the bloggers' videos. In his first videos, Maxim “disassembled” a 27-inch LightCom V-Max monitor.

And for analysis, he gave the general director of the entire Association of Services, Violin, a 24-inch LightCom V-Lite-S monitor, which contains the same controller board.

Yes, indeed, monitors produced by Lightcom use the same universal board. Why do we pay attention to this?

How different manufacturers make monitors.

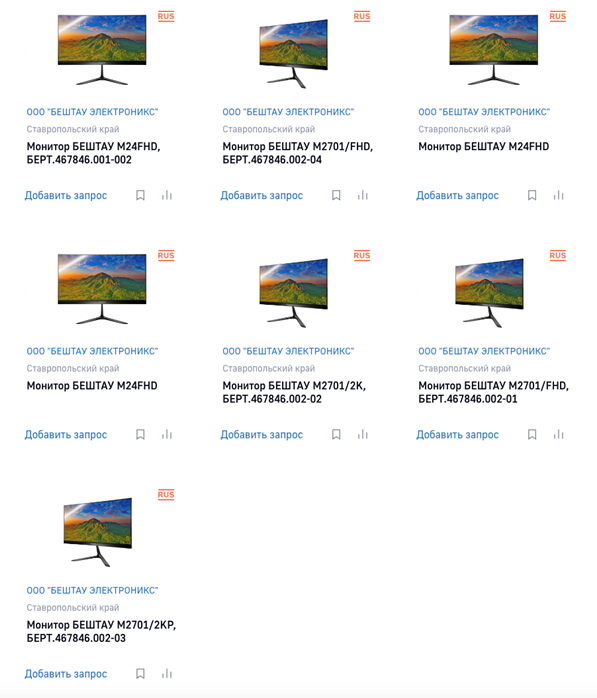

Different manufacturers produce different monitors, they may differ in appearance – different cases, different diagonals, different legs. Very similar monitors may have different internal components. Monitors can have built-in or external power supplies, different matrices, which differ not only in size, but also in the type of matrix technology. For example, Beshtau has 7 monitor models in its registry.

And for these 7 monitor models, the registry includes 4 controller board models. Other companies have a similar picture. RDV Technology LLC has 5 controller boards and 228 monitor models, New IT Project LLC has 4 boards and 4 monitor models. And only Lightcom uses one board for 17 models.

What is special about the monitor control board from Lightcom?

The manufacturer's idea is simple – to develop one universal main monitor controller board for all manufactured models. Why is this idea relevant for the Russian market?

The production volume of monitors from each of the companies we analyze currently does not exceed 100K units per year, but in reality amounts to only tens of thousands of units. Moreover, if you make different controller boards for different monitor models, the circulation of the boards becomes even smaller. Therefore, Lightcom decided to make a universal controller for all monitors and, due to a small technical redundancy, increase the circulation of boards, which should recoup the costs.

In addition, when including domestic products in the register, it is necessary to prepare materials for examination at the Chamber of Commerce and Industry and the Ministry of Industry and Trade for each board every year. And in order to reduce the volume of this bureaucracy by 4 times, many will go to greater lengths.

What does the Milandrovsky microcontroller do?

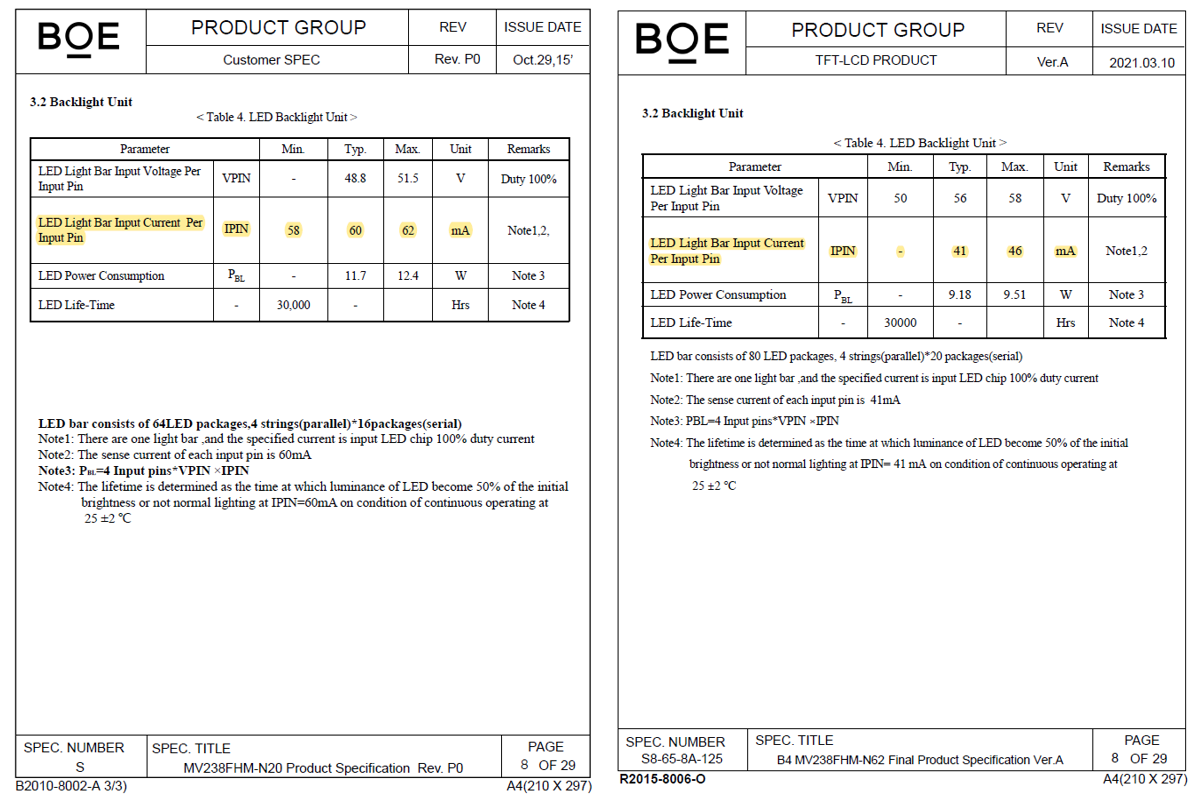

Let's show this on that part of the backlight circuit that Violin tried to figure out. First, let's look at how different LCD matrices may differ. One of the differences between different matrices is the current requirements for the supply current of the matrix backlight LEDs. The value of this current is specified in the documentation from the matrix manufacturer. And these requirements may differ even for interchangeable matrices from the same manufacturer. The current value is determined by the structure and principle of formation of that backlight white light in a specific matrix model. Violation of the required value leads to the appearance of spots or highlights on the screen.

To generate the backlight current, the Lightcom controller uses an OB3350CPA LED driver chip. And with the help of a PWM signal from the Milandrovsky microcontroller, the current is accurately adjusted. If the adjustment range using PWM is not enough, then using AO6800 analog switches you can switch the current-setting resistors to a different value and ensure operation in a different current range. The control signals from the microcontroller are marked in yellow on the diagram (provided by Lightcom). This ensures that the controller board can work with any matrix.

How does this work in the production cycle?

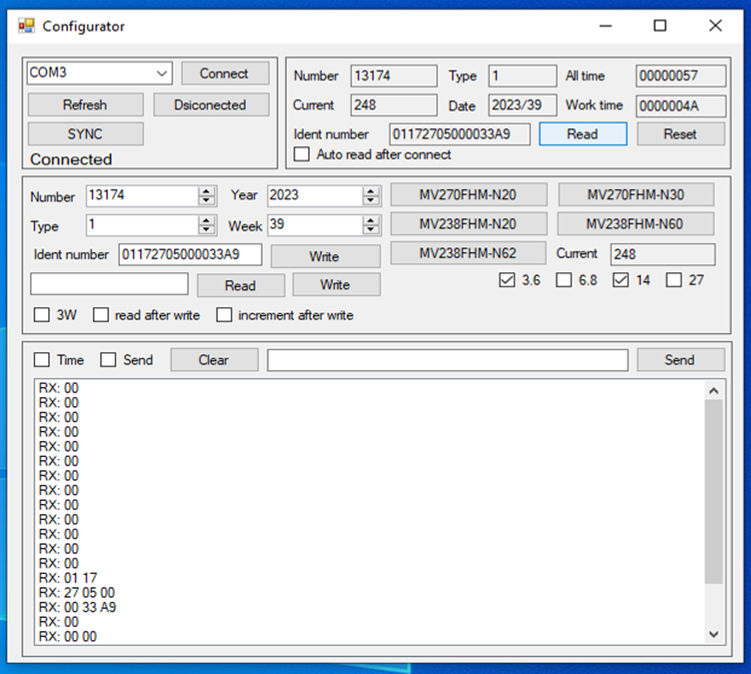

Lightcom orders the production of one large batch of completely identical monitor controller boards, saving due to the large volume of one order. After which, depending on the production plan and consumer requests, it launches a batch of the required monitor model for production. And depending on the type of model, it independently configures Milanda microcontrollers in software for the desired operating mode of this type of monitor. Below is a screenshot of the Lightcom software interface used in production.

In addition to setting the matrix modes, power management settings, the serial number of the board, the production date are written to the microcontroller, and the operating time counter is started. But this is no longer of much interest to the average user, even though it is of great importance for the manufacturer in terms of service. We will leave these functions and settings for future publications.

What happens if the microcontroller is removed or a little more about cheating.

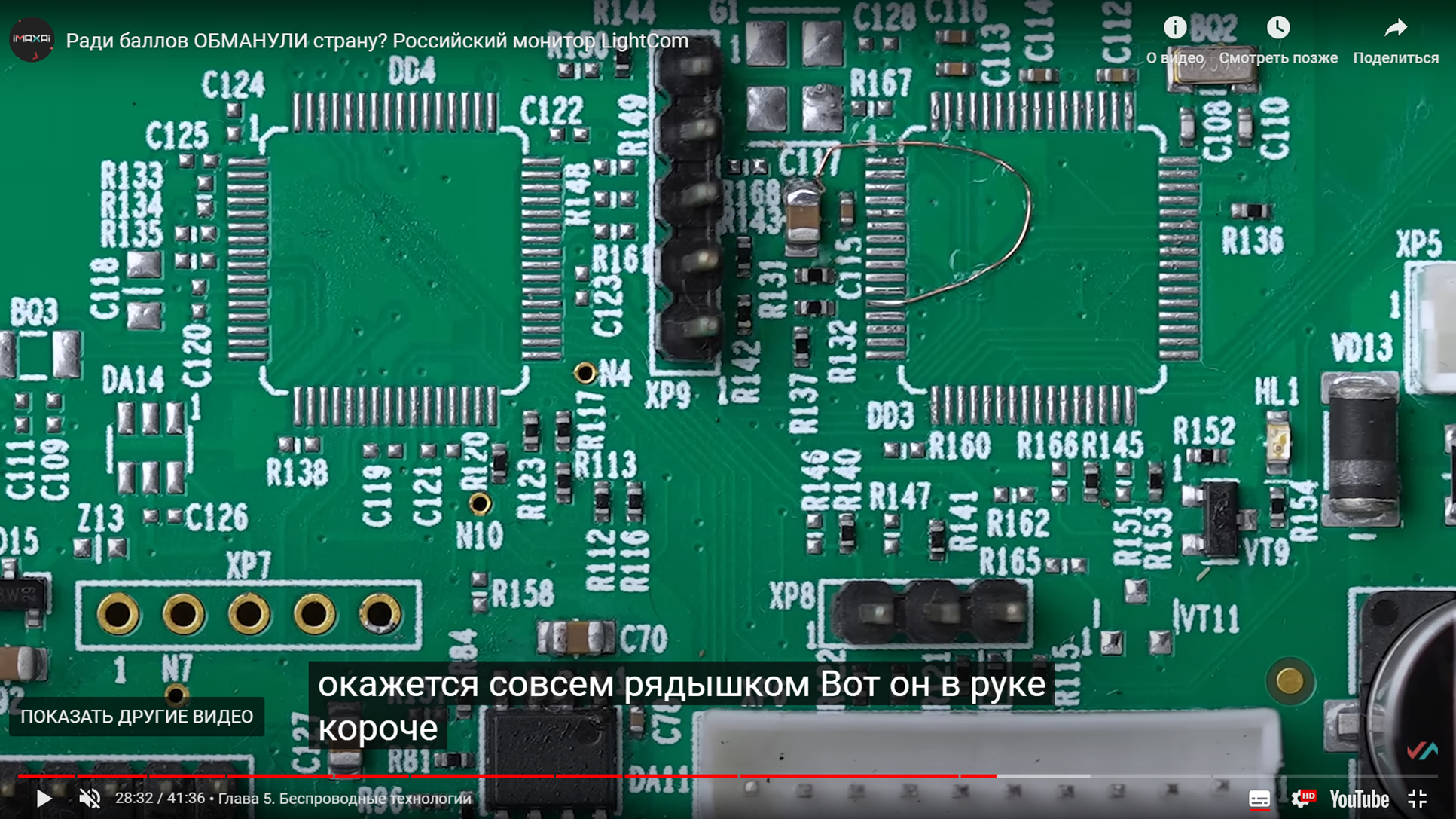

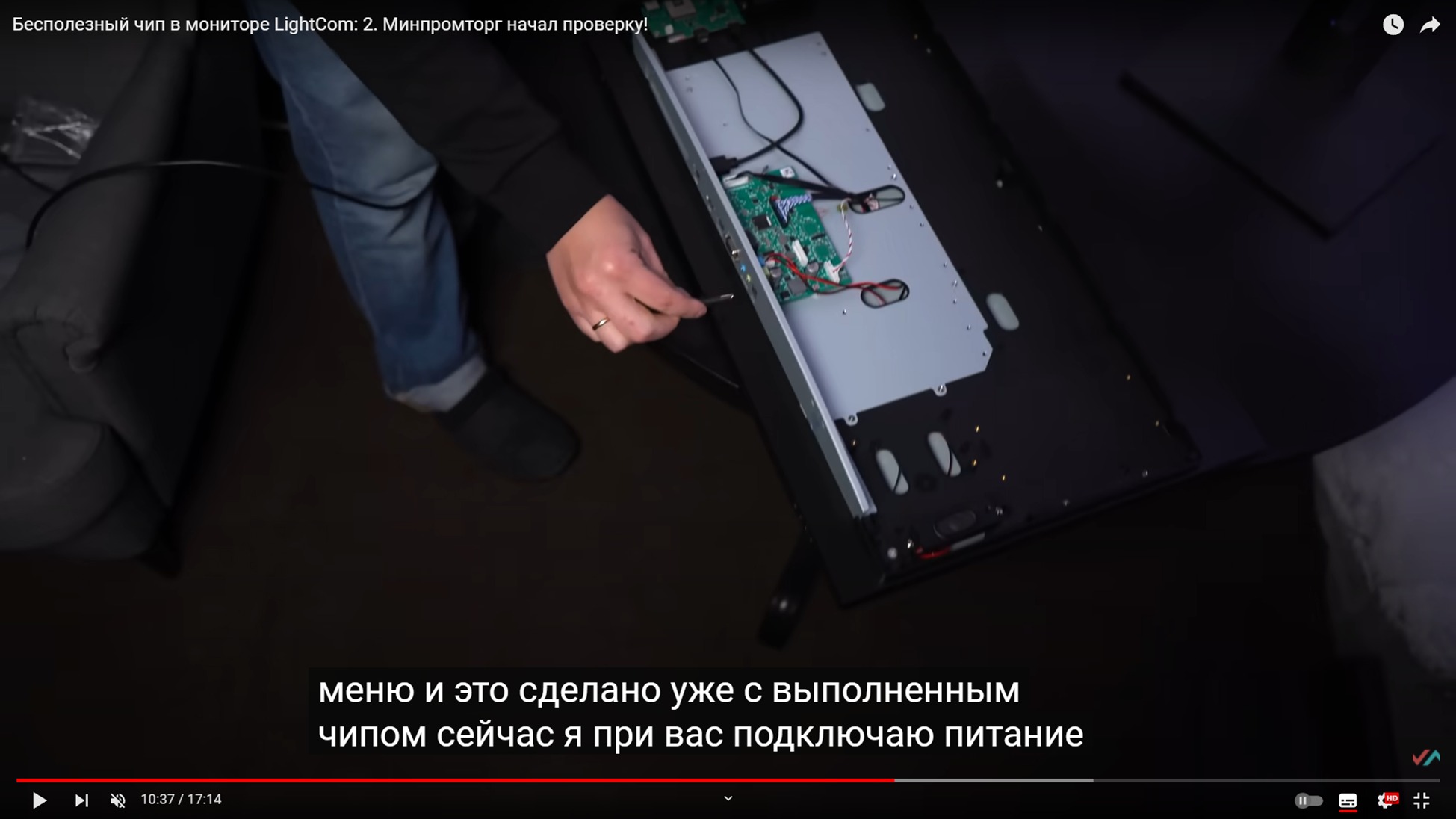

In his first video, the blogger argued that the microcontroller can be replaced with one wire.

After watching, many viewers tried to figure out what kind of pins the blogger connected to launch the monitor. Much confusion was caused by the fact that the K1986BE214 microcontroller was installed on the board instead of the K1986BE92 (as Lightcom explained, they had to switch to another microcontroller in 2022, since all K1986BE9x microcircuits produced by Milandr began to be supplied only to higher-priority customers). This, by the way, explains the presence of two slots for microcontrollers on the board. One under K1986BE92, the second under K1986VK214, but only one of them is installed.

So that very first delay from the blogger is actually not a signal to turn on the backlight source – it is a PWM signal for the OB3350CPA LED driver. The wire alone would not have made the monitor work. And many users found hidden fixes that the blogger for some reason kept silent about in his first video. After which he had to justify himself in the second video that there were more corrections.

But let's return to the first delay. If the ADJ_BUST signal is connected to power, then a constant high level goes to the PWM input of the backlight driver. This means that the maximum backlight current should be output, but even so the monitor brightness was still low. Which again they started pointing out to the blogger in the comments. And Maxim, in a brilliant directorial move, “solved” this problem in the second video – by turning the brightness menu to maximum.

Then Violin was able to adjust the brightness of the monitor, but perhaps due to his bias, on the contrary, he confused the audience even more than he understood the principle of operation.

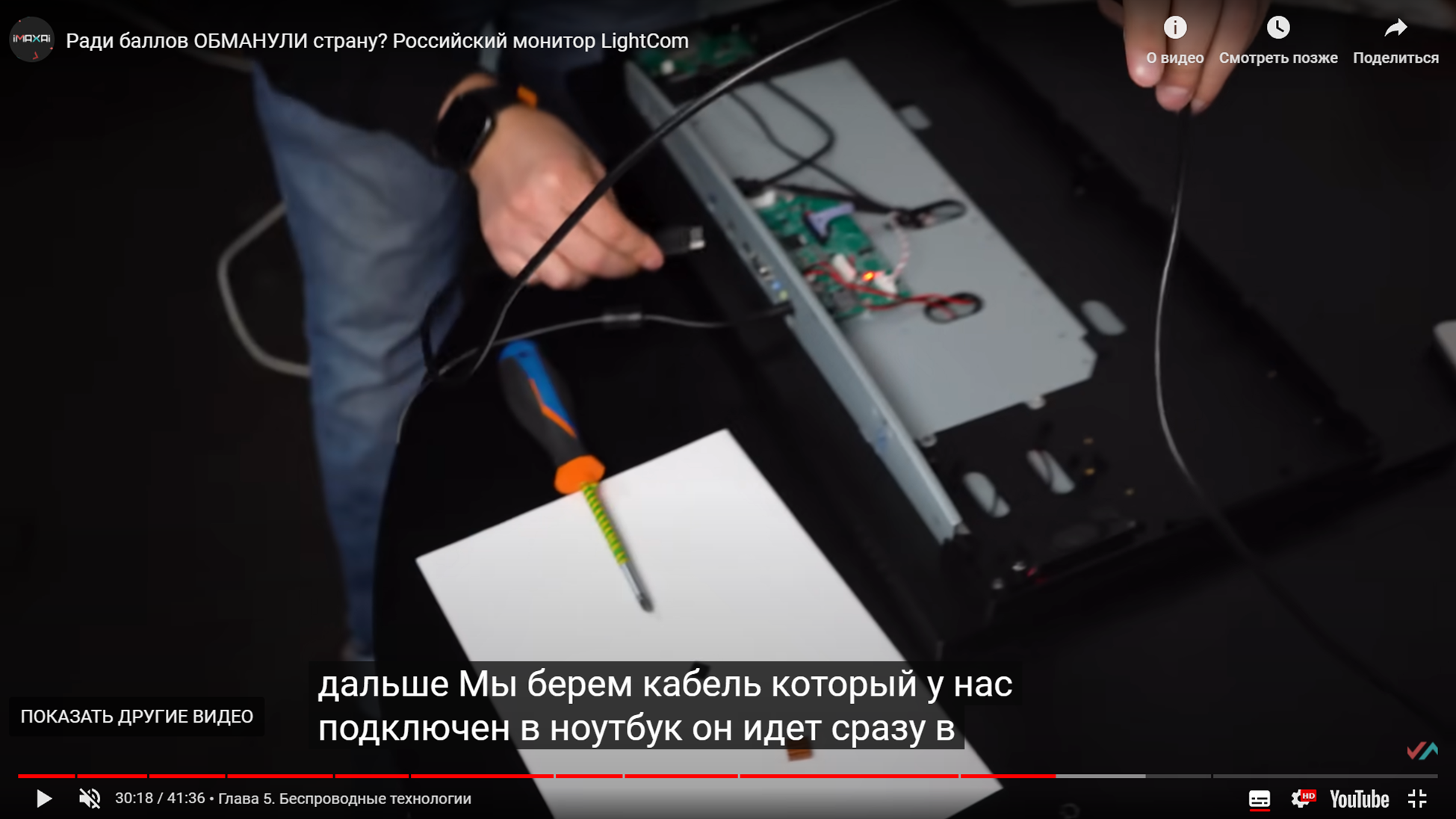

Maxim has a lot of “brilliant” directorial discoveries in his videos. For example, he always turns on the monitor when it is face down.

What is this connected with? Since the power supply sequence in the controller is broken, at the moment of turning it on and off, random garbage is displayed on the screen, which the blogger “hides”. A normally working monitor does not have this.

Let's continue about the blogger's talent. Maxim also masterfully plays on another problem. Please note that the HDMI cable is connected after the power is turned on.

“Yes, we've all done this a hundred times“- the reader will say. But, for example, Beshtau very competently prohibits doing this in his instructions.

The problem is that a conflict occurs in the scheme modified by the blogger. Power appears in HDMI before the RTD2525AR matrix controller chip starts up. And if the HDMI cable is connected, then the process of matching the video card with the monitor starts erroneously. And since the controller is not ready yet, in some cases the monitor is not detected. If you connect the cable manually after power is applied, then by the time the coordination begins, the controller chip has already started up and is ready to respond to requests from the video card. But are users ready to tug at the cable every time they turn on the power?

We don't care about Lightcom or the Milander microcontroller. But we specifically pay attention to dirty blogger tricks that are used for the sake of hype and shocking. Let everyone draw their own conclusions. For ourselves, we decided that one microcontroller in the monitor cannot be replaced with several wires. Otherwise, we will need at least one more blogger to rig HDMI cables and a service center director with a soldering iron for fine-tuning. And of course, in this case there can be no question of any seriality; thank God, we have only one copy of Gorshenin.

But now let's return to controller boards from other manufacturers. And let's prepare the ground for Maxim's new videos, in which he will probably say again that everyone deceived him? (https://www.youtube.com/watch?v=gxt0xDHYTn8)

Attention! Here's the most interesting thing.

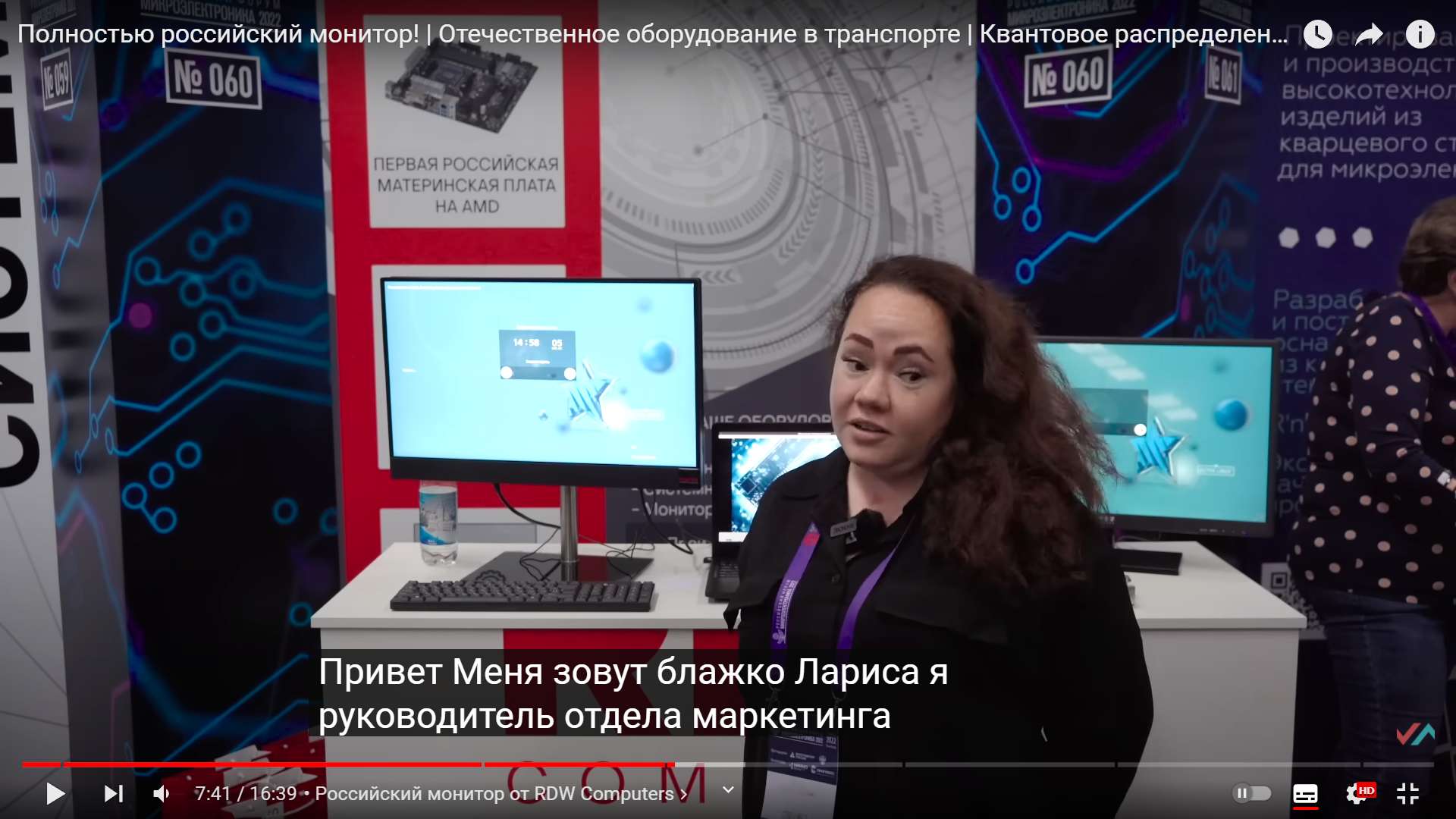

In our last article, Maxim for some reason ignored our questions about the domesticity of other controller boards. Probably because these companies did accept his terms of cooperation. And, judging by the video, they are great and do everything themselves in the spirit of the state policy of import substitution and as Maxim himself dreams of it. If so, then we were allowed to dig deeper and show you.

More quotes from this video 8.11. Gorshenin: Tell me more…

8.12. Blazhko Larisa, RDW: Monitors are our pride because everything, right down to the housing, is a Russian development.

8.20 Blazhko Larisa, RDW: We also developed a board to control the monitor. Not only our matrix…

And one more quote from this video. 1.57 Kravtsov, Graviton: We have a large, I would say huge, R&D area. We are talking about several dozen, now closer to a hundred, specialists who are engaged in the development of printed circuit units, the development of a general concept for devices…

There will be no quotes. Everyone already knows about Maxim’s love for Beshtau.

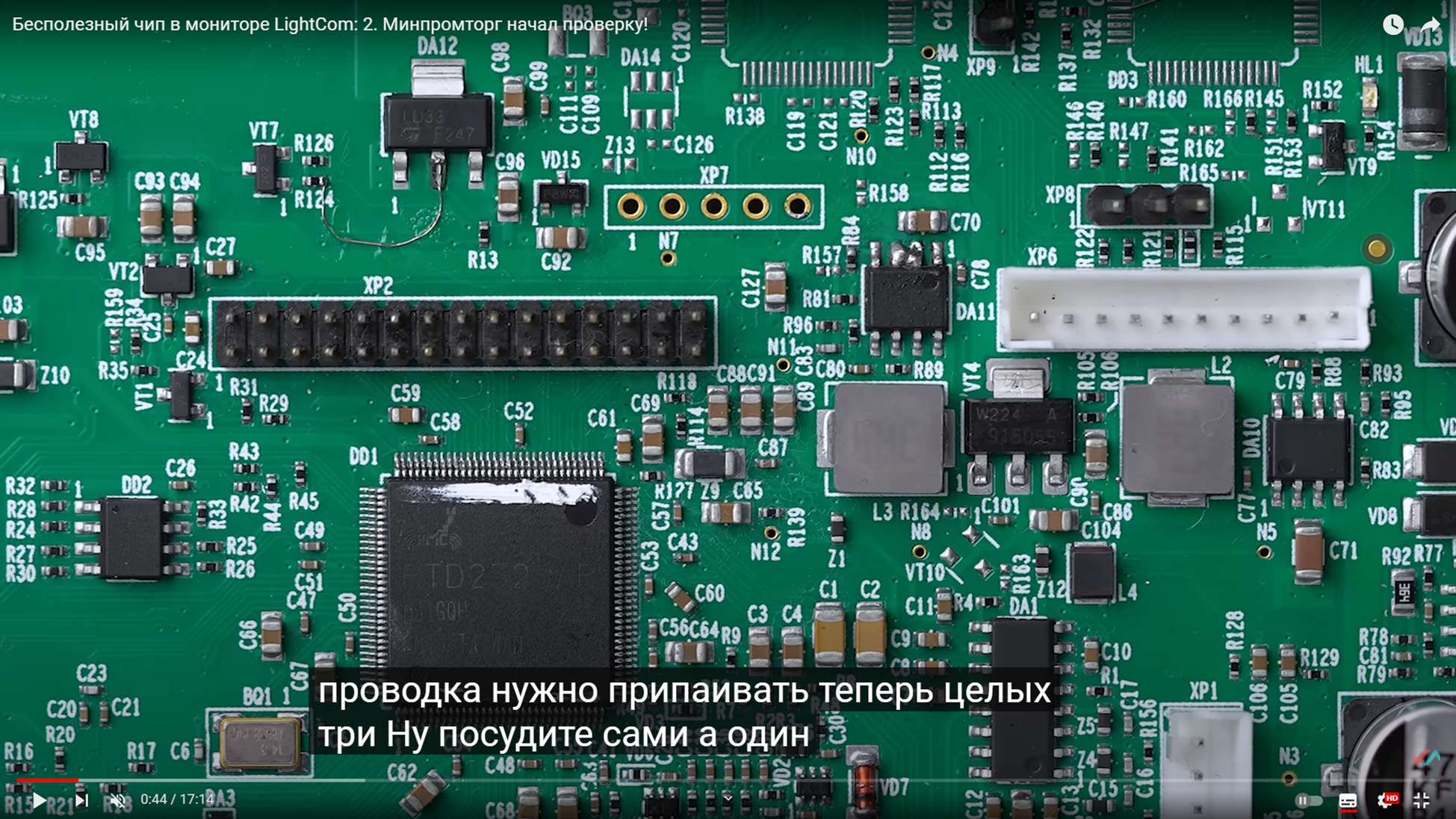

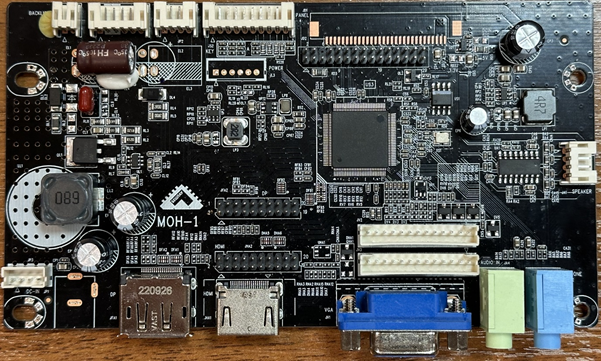

Have you looked at the boards? Don't you find them very similar?

Personally, we got the impression that all three of these boards were developed by the same author. To create differences, I simply slightly changed the location of some elements on it. At the same time, I used the same component library and implementation principles. The numbers and designations of components on the board, and the silk-screen printing of elements in some places match down to the smallest detail.

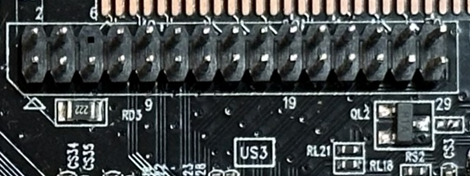

Matrix connector

MediaTek controller chip

Part of the power circuit

If among the readers there are specialists in the development of printed circuit boards, please give your opinion – could there be such similarities between different companies? Of course, we can assume that some cunning developer first worked in one company, after which he moved to another and took the project with him, and then repeated this a third time. If this is so, then he is not just cunning, but also a brilliant developer, because he was able to sell himself not only to Russian companies, but also to many global brands and even sells his boards on AliExpress.

How can everyone Russian and Chinese boards, do the MediaTek controller chip have the same number “US3” in the schematic?

Why did we decide that there is only one author? Because, like any brilliant author, he left signatures on his works.

Who is this mysterious JRY, who develops monitor controller boards for the whole world and for the best Russian import substitutes, according to Maxim? Dear girl Flora Hu from Shenzhen JRY Xinxian Technology Co., Ltd sends a huge greeting to you all! It is this company that labels all its products with the JRY code.

As a result, we once again determined for ourselves who is who in the market of computer hardware manufacturers and how creative they can be in an attempt to drown their competitors, so as not to develop the circuits themselves. The management forgave us, we were able to reassure our customers, who are now watching with interest the end of this story. And in our opinion, it turns out that of all the monitors we reviewed, only the Lightcom controller board is a completely Russian development. Despite all the negativity that was created around him. And the reason for this blogger circus was probably that the controller board for Lightcom was developed by Milander, and not by Flora from China. Do you think the Milander microcontroller is worth the extra points? Unfortunately, it doesn’t matter to us and our customer whether there are 90 of them or 140.

What's next?

The blogger will face trial in the near future.

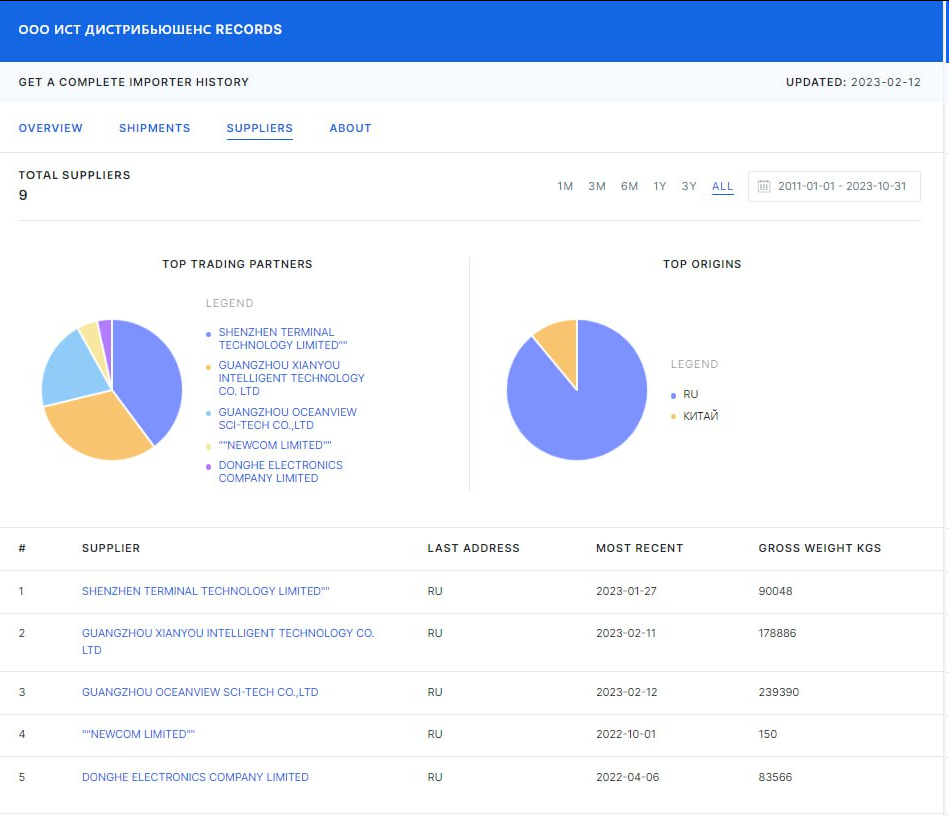

In addition, now when choosing suppliers, we also analyze their foreign economic activities. Who, what, from whom and how many tons are being transported from China?

Whoever is the first to build a logical connection from this picture with the defendants in this case will receive honor and respect. Thank you all for taking the time to study this article.