Inverter for motor over 100kW

For the first time in history, the Axiom open source project enables precise control of powerful 3-phase motors. Now this is more relevant than ever. Billions are being spent on approaching the era of electric vehicles. We see a huge increase in the development of electric cars. And a host of small and large companies competing for dominance in the future of transportation are doing just that.

Description

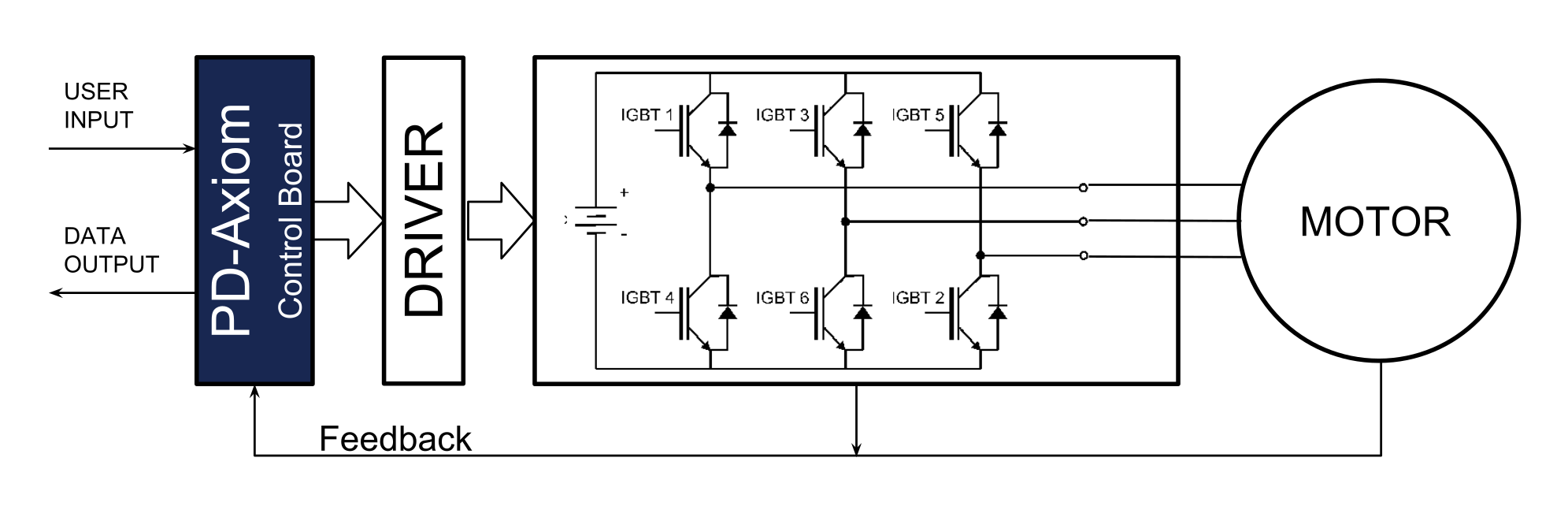

This is a 3-phase motor controller. A DC voltage is applied to the input and 3 sine waves are generated at the output to control the motor. Conceptually, the block is similar to small ESCs (speed controllers) for drones and bicycles. The difference is that this unit can safely operate with a 400V battery that can provide 300Amps continuously.

Our work has focused on a control board that is capable of delivering more than 400V with more than 300A of current, which is determined by the ratings of the powerstage (power stage) or power section of the unit, as well as the battery.

We chose economical IGBT modules because they are more common and easily purchased units. They come in different levels of voltage and current (from 600V to 1700V and from 100A to 1000A), from many brands, both in IGBT technology and SiC technology, and with ready-made key drivers matched to them.

Project idea

We want to participate in the most interesting, most impressive projects, and there is no other open platform capable of driving a 100 kW motor. All you can find on the market are high priced proprietary controllers with no way to customize them to suit your needs. And, most importantly, you won’t be able to get the source to see if the quality is up to your standards, both in software and hardware.

A new wave of electric vehicle companies have been involved with custom electric drives. This project provides an opportunity to deeply integrate the drive into their systems, giving a unique opportunity to adapt to their requirements. This saves costs and improves the quality of their vehicles.

The open Axiom project also demonstrates the quality of our work and makes our team a desirable contractor. There are not many people in the world who have the skill set and knowledge to produce inverters with such efficiency.

Axiom is also made possible by the fact that the platform VESC is growing steadily. For the first time, we can take it to the next level, from a hobby tool to full-fledged technology capable of supporting electric vehicles.

Who is it for?

Since we went public, some individuals and entire engineering groups around the world have signed up to order Axiom. We are currently in beta testing, only delivering the product to the most experienced engineering teams able to provide us with valuable feedback to ensure we deliver a reliable product. Over a hundred direct requests were processedhere are some of the commands that have the Axiom controller tested:

Approximately half of the applications are for traction vehicles (cars, bicycles, racing cars), others are for aircraft, and some are purely research and development units.

What is the block good for?

For almost everything related to powerful 3-phase motors:

Electric vehicle conversion

Electric car racing

Mining

OEM EVs such as bikes and ATVs

Underwater rovers

Aviation systems

Airframe launchers

Wind generators

Research and development

Why Axiom?

Many are familiar with and already using VESC systems. The system has a fairly decent level. The user needs an interface to customize his project. And it is very convenient to do it through VESC. The barrier to entry into this system is very low. You can show respect for the system VESC Benjamin:

Even with software and firmware, a high power application will still require very specific hardware:

Controller Benefits:

Mechanically optimized for installation on EconoDual IGBT modules. Quite compact, fewer assembly steps, fewer wires and crimps, no transition parts. Everything is assembled in one block.

The board has an isolated high-voltage DC/DC converter and a phase monitor. Direct connection to IGBT for better Signal Integrity and faster assembly.

The board has capacitor discharge resistors. A safety requirement that resistors discharge capacitors when the board is not powered.

High frequency connectors for measuring analog signals. This ensures signal quality and simplifies development.

Individual IGBT fault monitoring. You can determine which particular IGBT is faulty.

Separate fault LEDs for overvoltage, overcurrent and overtemperature detection.

Individual IGBT temperature control.

Lattice iCE40 FPGA using open source toolkit for HDL synthesis and development.

The FPGA continuously monitors all fault inputs. If any malfunction is detected, all PWM activity stops.

The FPGA controls the PWM generated by the MCU. Disables PWM when an error or malfunction is detected.

We implement this amazing motor control stunt in FPGA

RJ45 ports. It’s not Ethernet, they provide shielded twisted-pair wiring in the standard way.

Two analog inputs for control.

Two isolated CANbus interfaces.

BiSS absolute encoder support.

Sin/Cos encoder support.

Has a 15 VDC power supply for power module drivers. It has control of these voltages.

2 DAC outputs with RF connectors for visual control of control algorithms.

2 open drain outputs for controlling small loads or relays, for example for a pump.

More fuses, TVS diodes, more EMI filtering.

Here are some high resolution images:

An old prototype that can show insulation gaps. You won’t be able to see this on new boards because of the thick solder mask.

Sensorless motor speed control with power stage on IGBT (yellow channel – the phase under study, output to the DAC channel):

Lots of full speed changes:

This is control by a signal on the board, in practice we strongly recommend using absolute encoders on power units.

Perfectly clean signals measured directly on the ADC pins, transmitted through the DAC to the oscilloscope. Notice how the angle of the vector is perfectly tracked in the non-motorized -> motor-controlled transition.

A clear fault message is also present as an indication on the board. All indicators have signatures for convenience and speed of event interpretation.

Schematic top level:

The block specification can be view in browser.

Additional data, board data sheet and images will be available at: www.powerdesigns.ca as well as schematic and other design files.

The unit shown in the photographs is designed for continuous operation of 400 V 300 A.

How it works?

The power supply voltage (high voltage DC) is applied to the input of the unit and 3 sine waves with a shift of 120 ° are created using PWM to control the motor. In fact, it uses SVM modulation, which reduces the number of switching required and therefore switching losses.

While VESC supports drive motors in both trapezoidal and vector control, our boards only work in FOC (Field Oriented Control) mode. It’s just better for the application.

FOC is to align the sine waves with the actual field inside the motor and control it with a vector signal consisting of a torque generating current quadrature with flux (Iq) and a flux generating current (Id). There are many good resources on this topic, and you can see the actual lines of code doing the conversions.

There is a description of the history of the project and development prospects, not very related to the technical aspects of the article.

The biggest news about this project is the official presentation of the team that made it possible. HighHopes and Arlo1 are actively involved in the development, we worked together to release this control board, and we founded www.powerdesigns.ca to centralize all the project work we did together.

Arlo1 delivers the field experience with their amazing, record-breaking builds and tools, while HighHopes provides the complex math for every design decision, while Maxi and I do what we do best: design, CAD, firmware and production. And remember, this is the result of years of embedded software development by Benjamin Vedder, with whom we are already collaborating.

PowerDesigns must provide the collected fees to all interested parties. We can offer uncoated PCBs upon request, but the risk is very high and I haven’t seen successful builds where people have to assemble the boards themselves. Therefore, it is better if we take care of the assembly. Even better, if we provide a complete motor controller, we are working on providing such a solution.

Maxi (paltatech co-founder engineer) and I switched to firmware development and testing a few months ago when the hardware design was decided. All of the code we provide for these applications is carefully designed to integrate directly into the VESC codebase so it remains public and well maintained.

In terms of hardware, we have the math to fine-tune the trip points, which we can easily tweak at will by changing resistors, and the FPGA is a very powerful addition for co-processing and safety features.

It’s an amazing platform for research and for powerful builds, I don’t know of any controller with this level of power, with this quality and attention to detail, while the user can change the firmware at will.

Axiom is not yet qualified for aviation/aerospace applications.

And now you can watch a video about this project.

The project is open and all the necessary sources can be found on the Internet in the public domain.

https://github.com/vedderb/bldc

http://www.powerdesigns.ca/files/Datasheet-Axiom-control-board.pdf

https://endless-sphere.com/sphere/threads/axiom-a-100kw-motor-controller.89056/#p1458465

https://cdn.hackaday.io/files/1649327056450688/Axiom_Rev1_schematic.pdf