In Russia, they began to build a factory for the production of 28-nm chips. But it’s not that easy

The other day it became known that in Zelenograd they started building a factory, which, according to the plan, will produce processors according to the 28 nm process technology. This project has been developed for a long time, but its implementation has only just begun. In general, the project is interesting, but many problems may arise during its implementation. About all this – under the cut.

What is this project

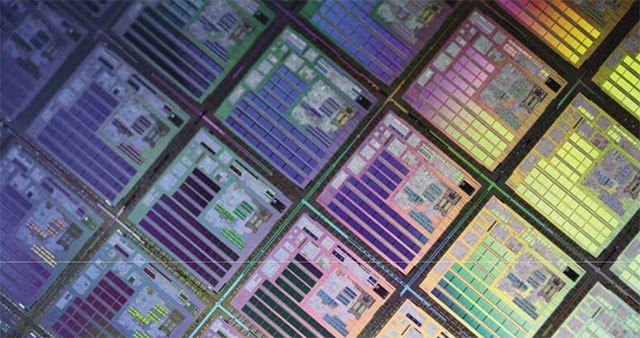

There is a construction site in Zelenograd where work on the construction of the factory has started. She, according to the plan, will produce processors using 28-nm technology, which will be used to assemble domestic electronic devices of various types. The construction is planned to be completed at the end of 2024, but, of course, this does not mean that the factory will immediately start producing chips.

The factory is being built as part of a large-scale plan for the development of the domestic electronics industry, the plan was approved two years ago, in 2020. The national project is designed until 2030. Its author is the Ministry of Industry and Trade of Russia, 22 working groups participated in the preparation of the document. According to the plan, the state plans to invest 3.19 trillion rubles in the project. The funds will be distributed in four main areas – for the development of infrastructure, domestic electronic products, increasing demand for it and the personnel component.

At the same time, the plan states that by 2024 it is planned to provide “100% import substitution in all areas”, and by 2030 “complete the formation of a product portfolio of Russian technologies”. 1.14 trillion rubles are allocated for the implementation of this area. True, another document says that by 2030, about 30% of Russian households will start using, for the most part, domestic electronics. As for the mentioned 100%, this figure is relevant for public procurement of equipment.

In addition to the 28-nm factory, it is planned to establish the development and production of microcircuits using the 90-nm process technology in Russia. In general, the technology is in line with what Intel used to release its own chips in 2003.

Construction is being carried out on the site of two demolished old Angstrem buildings. The total construction area is 50 thousand square meters. The buildings will house the research and educational infrastructure of the Moscow Institute of Electronic Technology.

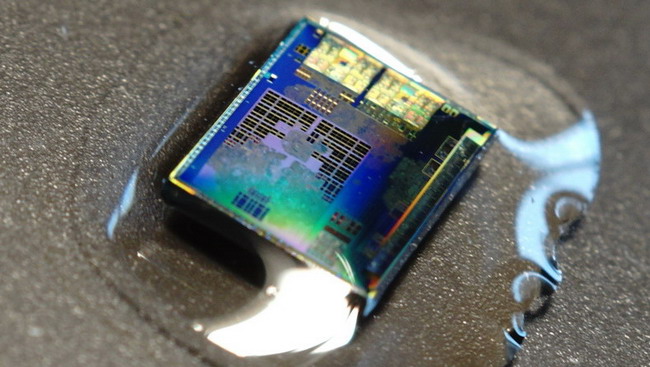

As for the developer, this is the International Science and Technology Center (ISTC) MIET, which was created on the basis of the university in 2020. By the way, it was planned to purchase a 28-nm laboratory-research line with an immersion photolithography section from the Dutch company ASML for the factory. But in the current conditions, it is not entirely clear how this purchase will be carried out.

If you are reading our blog, you may be interested in these texts:

→ How to optimize spending on infrastructure rental

→ Ready-made container registry – who needs it and how to use it

→ How we launched a remote cloud region in Uzbekistan

Some more details

Several low-rise buildings will be erected on the site – from two to four floors. Previously, the construction site housed two two-story buildings, which were built back in the 70s of the last century. A couple of years ago they were demolished, now they decided to use the empty site for the construction of new buildings.

At the same time, it is planned to upgrade the entire territory of the Angstrem plant, the entire site belongs to the Technopolis Moscow special economic zone. The renovation consists in the reconstruction of some old buildings, as well as the demolition of many unnecessary buildings. The total area of buildings that are currently on the site is about 153 thousand square meters. m. After reconstruction, this figure will increase to 500 thousand square meters. m.

The authorities plan to switch to 28-nm technology by 2030. It is worth noting that foreign manufacturers have mastered the 4nm process technology and are gradually implementing plans to develop chips using the 3nm and 2nm process technologies.

As for the domestic project, its drafters declare that by 2030 at least 400 prototypes of new types of electronics will be developed and at least 2,000 research projects will be carried out.

What are the problems?

A lot of them. For example, according to the same plan, by 2030 the number of design centers should increase to 300. At the same time, it is planned to create a team of specialists of at least 100 people in each of them. It turns out that the total number of specialized specialists will be about 30,000 people. But in Russia, there is already a fairly large-scale shortage of IT professionals, and if it is planned to invite 30 thousand people to work in 8 years, then, in fact, they should already enter universities with a specialized specialty.

The second problem, even more serious, is equipment, including lithographic machines. Now it is said that they need to be developed in Russia. But the components for such systems are all completely imported. Perhaps most of the components can be obtained in China. But if at least something is missing, then the production of lithographic machines will not begin.

Next – resources for the production of chips. For example, photomasks, the production of which seems to be set up in Zelenograd. But they need imported glasses for them, a similar situation is with the resist. Silicon wafers are produced in the Russian Federation, but the ingots from which they are cut are imported, the cutting equipment is also imported, as well as consumables for it. At the moment, there are supplies for several months, but what to do next is not yet clear.

Another problem is that the chip manufacturing plant requires support of hundreds of millions of rubles a year, and it does not matter whether something is produced there or not. Accordingly, the cost of production can be very high if small volumes of chips are produced. The higher the volume of production, the lower the prices. And if the domestic market can and will buy millions of Chinese chips (processors and GPUs) from China, then in the Russian Federation the market is smaller, so the cost of chips will be high in any case.

In general, the fact that Russia is starting to work on expanding its own semiconductor industry is very good. But in the course of this work, many problems will have to be overcome, many of which are critical to the ambitious plans developed in 2020. If all these problems can be solved, then Russia will be able to get its own chips and use them in the domestic industry, plus, perhaps, sell something abroad. How things will be in reality is still unknown, but in a couple of years it will be clear.