Government procurement, “Growth Point” and a 3D printer for triple the price. Four years later

Disclaimer. This story began at the height of the pandemic, in September 2020. Over the past years, I have managed to tell some of its episodes on my personal blog, on one specialized website for 3D printers, and even made a video for my Youtube channel with 3 subscribers. However, quite recently (in March 2024) the story was continued, and I decided to put some of its fragments together and tell it to a wider audience, because… But about this – at the very end, for now…

…It all started in September 2020, when schools in our region (including my home school) opened Tochka Rosta centers. It's a good thing, in principle. But there is one big “but” – by the beginning of the 2020/21 academic year, the promised equipment was not delivered to the school. It was not delivered by the end of the year (calendar). Although the government contract (through the notorious State Procurement) was concluded back in June and the deadline for delivery of goods under it expired somewhere in mid-November (for those interested – Contract is still available online and can be studied). A certain company from a region neighboring ours won the contract (I won’t give the specific name here, for those who are interested – everything can be found in open sources). Judging by information from the Internet, this is a typical out-grower, selling everything. The contract, by the way, included everything in a row – furniture, chess, quadcopters, laptops, virtual reality helmets, 3D printers, mannequins for practicing artificial respiration, tools (such as jigsaws) and much more. It is clear that the chance of finding a good supplier for such a unique assortment was immediately slim (well, they usually don’t sell quadcopters and chairs in the same place!). In general, 3D printers are a special topic – they are, essentially, piece goods. Especially for those characteristics that were specified in the technical specifications for the purchase (I can immediately remember only a couple of models that fit these conditions). Plus, the contract was concluded for huge quantities of goods – for 46 schools within the region.

And without all these devices, classes are essentially meaningless. What's the point of modeling things for 3D printing if you don't have a 3D printer? What's the point of learning to fly quadcopters (aka UAVs) if you can't hold them in your hands? What's the point of learning to work with augmented reality if you don't have virtual reality glasses? That's right, it makes no sense!

And finally, in mid January 2021 year, the supplier was able to collect from the world all the necessary devices (and everything else), and the equipment went to schools (also not without incident, because the supplier could not organize a sane delivery; some of the equipment was literally unloaded on the street at the school porch and had to be brought into the building on your own). Of course, there was no talk of any commissioning of complex equipment (schools are full of specialists in 3D printing and drone assembly!).

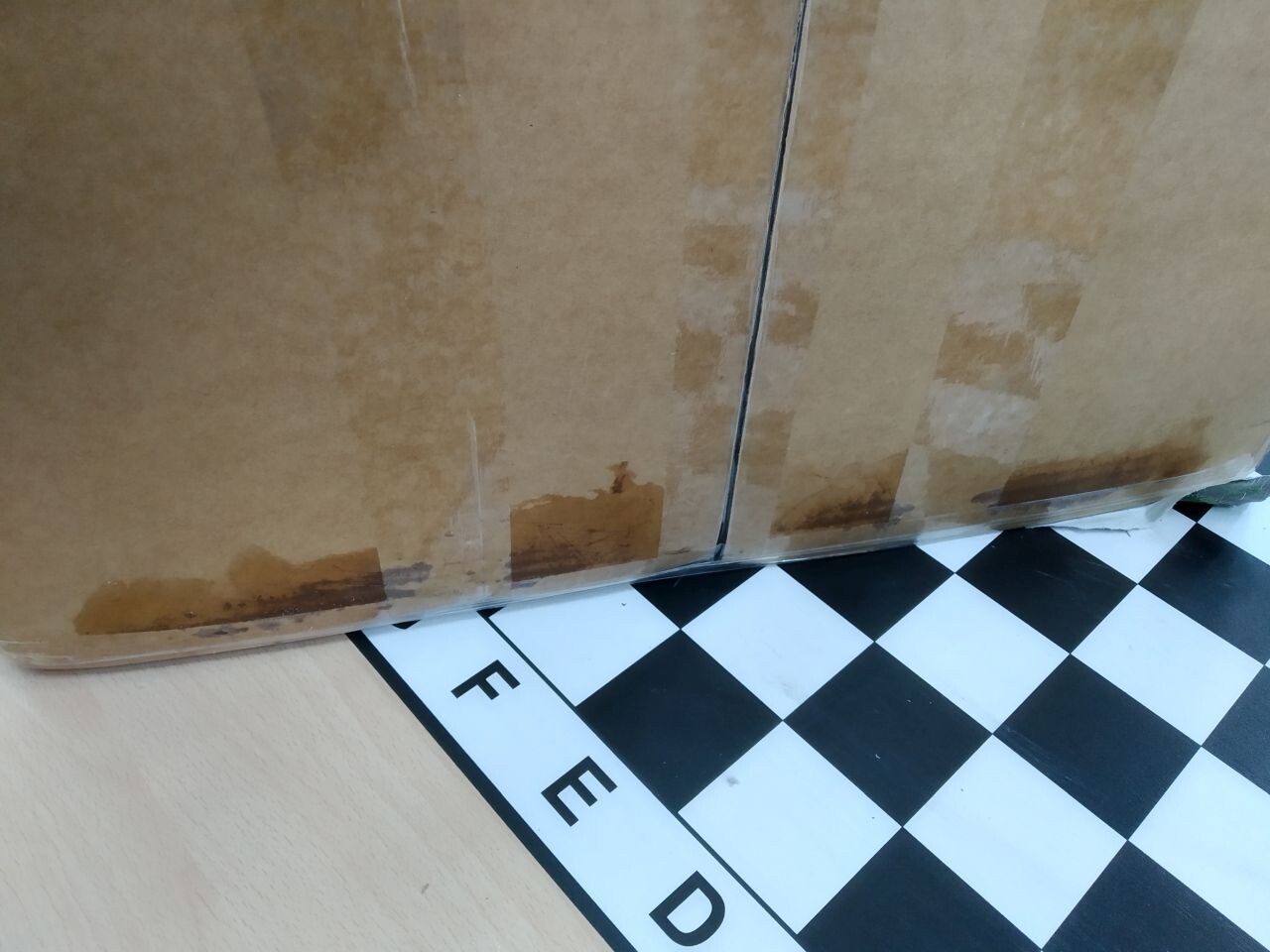

I’ll leave out the numerous jambs with other equipment. Although the chess table alone with an incorrectly drawn (sic!) chessboard is worthy of a separate story. I will dwell in detail on the most expensive part of the kit – the 3D printer. The first suspicions began to creep in when I saw the packaging. The printer was wrapped in gift paper with the inscription “Happy New Year” and tied with a bow. Moreover, the paper was attached to the box with a furniture stapler. After opening the package, the bad feelings only intensified – inside was an ordinary cardboard box without a single identification mark. Moreover, the bottom of the box was soaked – it obviously stood in a damp room right on the floor. I suspect that it was precisely to hide this problem that our “gifts” were packed extra.

Okay, let's look further. And then I opened the box (sealed with ordinary tape in several layers) and took out the contents. This:

Actually, in addition to the device itself, the box contained only a small box with accessories.

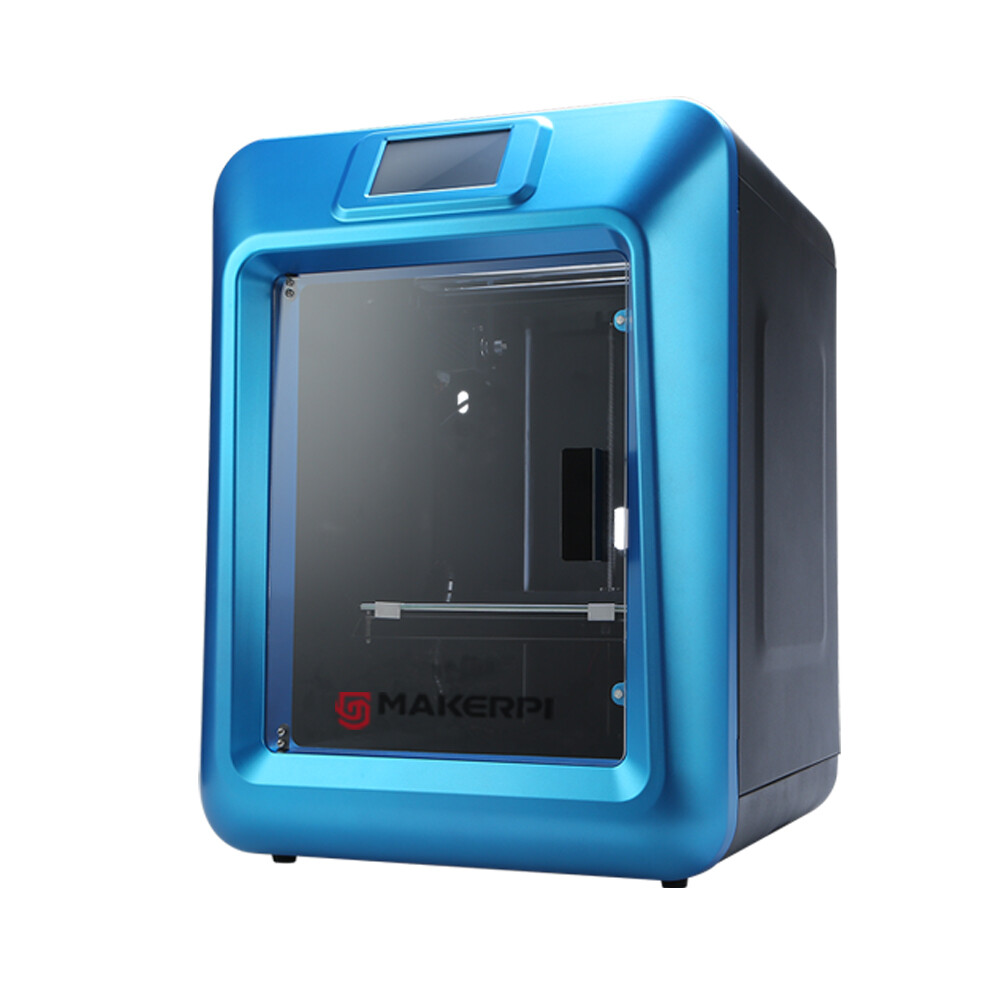

A quick inspection of this device will not allow you to determine even the exact model – the kit did not include instructions or a technical passport (which is mandatory for equipment supplied under the state contract). Using the name of the manufacturer, we were able to find the official website with some technical characteristics. The page on the site exists still, but the description has been slightly corrected over the past 4 years. In particular, they removed the price, which in January 2021 was 150 thousand rubles. Yes, yes, you heard right – 150 thousand! No, I understand that a high-quality 3D printer is not a cheap thing. But is the product that came to our school a quality printer? Looking ahead, I’ll say straight out – NO! As my simple investigation showed, the only thing that is domestic in this machine is the logo on the door and a dull box without identification marks (although even this is not a fact!). In fact, this printer is a purebred Chinese. Specifically – MakerPi 3D printer K5 Plus. Here he is:

As they say, find 10 differences. However, there are differences. Firstly, the Chinese in January 2021 cost only 48 thousand rubles on Aliexpress. (in April 2024 – a little more than 63 thousand (proof), but how much a “domestic” clone costs now is another question). Secondly, it comes with a laser engraver. Thirdly, it has a top cover made of plexiglass (well, or something similar), whereas the domestic version did not have one at the time of delivery.

In general, business is Russian. One “manufacturing company” buys inexpensive printers in China and sells them at three times the price in degraded configurations. The second company supplies these printers wholesale to schools throughout the region under a government contract. Everyone is happy. Except for teachers and schoolchildren who will have to work with this rubbish.

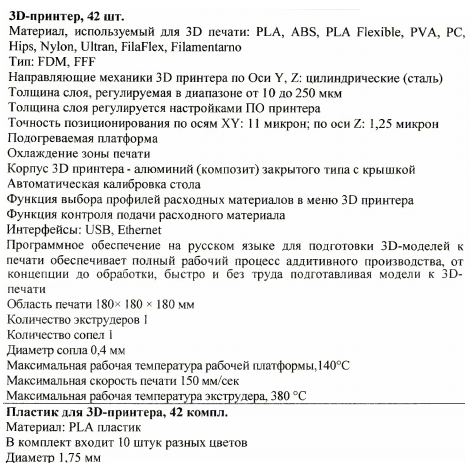

In the next week, I studied the resulting miracle of “domestic” electronics in more detail, and at the same time conducted a little investigation. To begin with, I propose to study the technical specifications according to which this printer was supplied to the school (the same printers were supplied to other schools in the region; this was later confirmed by colleagues).

So, let's see what kind of printer was brought for this specification. The outside looks quite normal for a “cube” printer. The body is made of metal (possibly steel; in any case, metal is highly magnetic) with powder coating. The corners are curved to provide vertical rigidity. But with lateral rigidity everything is worse – the top cover of the frame is made of plastic (ABS) and does not look rigid.

Kinematics – ulti-like Cartesian. Everything moves on shafts (8 mm along the X and Y axes, 12 mm along the Z axis). The Z axis is on a screw and two shafts. The screw is connected to the stepper motor through a simple continuous coupling. When the table moves, there is a beating of the axis (either the screw is bent, or there is a misalignment somewhere).

The table itself is made according to the “sandwich” principle – there is a steel platform at the bottom, then there is a heater, a sheet of aluminum, finally – glass and a polymer film glued on top of it (at the time of the first acquaintance I thought it was PEI, but now I am sure that it is something cheaper and simpler – like the standard Kingroon KP3 coating works well, but the durability asymptotically tends to zero).

Since there are no proper instructions included with the printer (only 5 pages in PDF on a flash drive), I had to look for information on the Internet. And it turned out that there is practically no information on this printer. In principle, this was clear as soon as I saw its name – which I had never seen before to this day (and I have watched/read a lot of reviews of all kinds of printers over the previous couple of years). We were only able to find the official channel on Youtube, where there are as many as 5 videos. More than half of them are dedicated to a laser engraver, which we do not have. The remaining two videos are instructions for installing the firmware (does not make sense, since there is no new firmware) and instructions for the first launch and calibration. I suggest watching the video from the official source:

What's it like? Or what is it like? The “manufacturer” proudly calls this process “automatic calibration”. As for me, an ordinary piece of paper is easier. Pay special attention to the inscriptions on the screen. They completely betray the origin of the printer (obviously not Russian).

In the process of calibrating our particular specimen, it turned out that the left front corner of the table was strongly curved and the length of the standard screw was not enough to compensate for this curvature. But the right front adjusting screw was not secured to the table and turning it did absolutely nothing. I had to use narrow pliers to complete the calibration.

In general, as it turned out later, this original calibration method in the future creates huge problems in the further operation of the printer (all the colleagues with whom I had the opportunity to communicate encountered this). The problem is the almost complete impossibility of replacing the nozzle (and even more so the thermal barrier!) on this machine without dancing with a tambourine. Yes, formally, you can easily put an E3Dv6 cube here and rejoice. But calibration after this will become a pain. One colleague and I, after reassembling the hotend, got out of the situation by putting an overlay on the standard calibration “sensor” with a thickness equal to the difference in the height of the hotend (damn, it even sounds like a perversion; in fact, it is).

After calibration, we will study the printer menu. The settings are the bare minimum; there is a “choice of plastic type” from two options – PLA and ABS. But these are all minor details; printing parameters can be configured in the slicer. And here is the most interesting section of the menu:

And here everything finally falls into place. “Production company Robokinetics” was too lazy (or did not manage) to modify the firmware, and the real model of this printer is reflected there – K5/K5 Plus. Google very quickly found the original of this device – the Chinese MakerPi K5 Plus printer. As I said above, find 10 differences (hint – the Chinese have a price 3 times less, have a laser engraver and a completely closed case).

Actually, the review could be completed here, because… I couldn't get this printer to print. Due to a firmware bug, the printer incorrectly “knocked off” the origin of coordinates and tried to hit its head against its own body. Also, loading and unloading filament worked the same way (i.e., the extruder motor rotated in one direction), and it was not possible to unload the filament at all.

But even with a non-working printer, you can find several more shortcomings. The first is a very original cable through which the print head is connected. Usually they try to protect this cable in every possible way, because… he works on a hot table and is subjected to intense loads from the accelerating head. But the Chinese who made this printer (and we can confidently say that this is a purely Chinese model, to which the “Russian manufacturer” added only its logo) decided to do without these conventions and make this cable:

Considering that the technical specifications stipulate a table temperature of 130 degrees, the inscription “withstands temperatures of 105 degrees” on this cable looks like a mockery of common sense. I’m willing to bet that with average intensity of use, this cable will not last long (at the beginning of 2024, some colleagues have a cable in terrible condition, but it still works; however, these printers work very rarely for most).

The second point that I would like to draw attention to is the attachment of the PTFE tube through which the filament is supplied to the extruder. Most printers have a press fitting installed in this place, but in this case the Chinese again went their own way and installed… a rubber gasket. This was done, apparently, in order to reduce the weight of the direct extruder. But saving a few grams led to severe inconvenience when using the printer – the tube constantly falls out of its mount. However, it also has its advantages – since the extruder likes to chew on plastic, you still have to remove the tube regularly.

I also made a short video review of this printer. Just so that fellow sufferers get at least some idea of what they have to work with.

By the way, the printer came with PLA plastic, the name of which coincides with the name of the printer – Element 3D. In terms of quality, the plastic is normal; the FlyingBear Ghost 5 purchased for our school in the spring of 2021 ate 5 kg in a few months. But the quality of the winding is simply terrible. Already on the first layer the overlap is visible to the naked eye. And there is no production date on the boxes (not to mention the batch number). But there is a proud inscription – “Expiration date – 1 year from the date of manufacture.” And the coils are 500 grams each. And even this corresponds to the technical specification – after all, it says “10 reels of different colors.” They could have put 10 pieces of 100 grams each.

This story will continue in the summer of 2021. By this point, the regional Ministry of Education was inundated with complaints about the quality of the supplied equipment, and officials responded. True, in a very original way. All the schools involved were sent an “examination report” from the ministry, which details why the supplied equipment fully complies with the technical specifications.

Full version of this document I posted it on Google Drive so that anyone can familiarize themselves with this masterpiece.

The examination was carried out by the best 3D printer expert in our region (this is my value judgment, if anything):

Then, ideally, you need to read the document, looking at that same 3D printer and either cry or laugh. Since the dear readers of this publication do not have a would-be printer at hand (well, except for its suppliers from the city of Podolsk, who rest me on the already mentioned profile site, and, perhaps, my colleagues, if any are reading this article), I suggest reading what was written above, watch the video review, and then read the expert’s opinion.

To be honest, after reading this masterpiece, I began to doubt the acuity of my vision. Well, I don’t see either a transparent plastic cover (which the Chinese original, which costs three times less), or a technical passport. Selecting the filament type from the printer menu is also not available on our copy. As for the maximum extrusion temperature of 380 degrees… I wonder if the “experts” actually tried to heat the extruder to this temperature? There, the printed fasteners will most likely leak at this temperature. Let me remind you that the Chinese have lower temperatures (I'll remind you of the link for proof).

I won’t talk about the other “expert” devices at all – we absolutely definitely received a different camera, and the quadcopters formally most likely correspond to the technical specifications (but they arrived incomplete and with instructions from a different model).

But as for the 3D printer, I have two versions:

1. Another copy was provided for “examination”. Or even another printer with the “Element 3D Box” sticker (the report notes that the examination was carried out under video recording – it would be interesting to take a look).

2. The “expert” did not see this equipment, but signed the document without looking (and, most likely, it will later turn out that this person no longer works for the “Expert Corporation”).

And back in July 2021, an investigator from the Department of Economic Crimes (or whatever this department is called now) came to the school and examined the equipment of the “Growth Point”. Unfortunately, I myself was on vacation at that time, and they examined me without me. But I hope the investigator did not see a “transparent plastic cover” on the printer.

The next round of the story began in January 2022 (a year after the printer arrived at the school; the printer sat in the box all that year). By order of the regional Ministry of Education, the defective “domestic” printer was transferred to the school’s balance sheet. Shortly before this (after the miraculous examination), all schools that received such printers received “add-ons”: device passports and top covers. Just look at these formulations:

Well, like our printer can do 380 degrees (as required by the technical specifications), but for schools we have locked this thing to 240 degrees for safety reasons. Bring it to our service and we’ll unblock it. Of course, we will take printers from the Vyatka outback to the Moscow region…

And so that the printer fits the definition of “closed”, we were given the following caps:

It feels like PET molded on a vacuum press. The geometry is so bad that the cap arrived immediately cut (without this cut it simply does not fit on the printer). I don’t even want to check what temperature it will withstand. Pornography in its purest form.

Okay, I’m not going to print with ABS at school, and, in general, I don’t need the lid (except to cover it from dust at night). But I hope the supplier of these items will have a problem. He will be remembered for a long time in 42 schools in the Kirov region.

Since the printer is already ours, I’ll open the basement to study it. The picture is not very encouraging.

We have an unknown board based on the STM32F407 controller. Manufacturer – Soongon (this is the printer manufacturer, if anything). Moreover, the layout of the board is very interesting – the controller itself is installed on a removable board (in the center of the photo), which is installed in Arduino-type combs (PLS, I think they are called).

The board itself with the controller looks like this:

In the lower left corner of the main board, a WiFi adapter is connected through a creepy 2-story adapter. The adapter itself is hidden in the depths of a plastic case nearby. And it looks a lot like an ESP32 installed in another adapter (in total, I counted 4 connections on the way to the main board – Wi-Fi adapter).

The power supply (according to the labeling) is Mean Well at 200 W. Hmmm… But initially this printer can burn with a laser. I doubt that 200 W is enough for this.

Motors and axle limit switches are connected as standard. The screen is the same (only the cable is very long, since the screen is installed in the upper part of the case). I didn’t get to the screen itself; its underside is hidden under the plastic housing casing. But something tells me that there may also be a non-standard solution here.

But the connection to the head is completely non-standard. In the corner of the main board there is a connector with a lock (same for all leads to the head). A prefabricated multi-colored wire leaves from it, coming under the “floor” of the printer to the adapter board. And from this board a thin cable goes to the head. You give more adapters and extra connections!

Another interesting aspect of the electronics of this printer is the drivers. Quite ordinary TMC2208 are installed on all axes, but the extruder is equipped with a certain A4982. No, I was not mistaken in one number:

In general, the picture is as follows. It has a printer with good mechanics, but very non-standard Chinese (in the worst sense of this concept) electronics, stuffed with non-standard solutions.

There is no firmware for this, as I already said. In any case, I didn’t find “Robokinetics” on the website (what happened was removed from the website back in 2021; I wonder why?). I tried to request the firmware from the Chinese (I found an email on the website), but they politely sent me to Robokinetics. Like, you didn’t buy from us, it could be a “custom” version – we won’t give anything.

After that, I gave up, put the printer in a corner, and forgot about it for another year. And so, early 2023 The Ministry sent letters to all schools asking them to report any problems with the equipment, because they are planning to file a claim with the supplier before the warranty period has expired. (by that time, the governor in our region had changed, by the way). Of course, I immediately described in vivid colors all the real problems for which you can ask the supplier (problems with the origin of coordinates and loading/unloading plastic; at the same time, we decided to return the incomplete quadcopter). Spring 2023 the faulty equipment was taken to the ministry…

And now, after about a year (!), at the beginning of 2024 our long-suffering 3D printer returned to school (the copter has not been returned at the moment). Everything is in the same stained box. To be honest, I don’t even want to check this product yet. Firstly, the warranty has already expired in any case, and any mistakes will now be purely my headache. But at the end of the school year there is no energy or time for this at all. Secondly, our old Ghost5 has been coping quite well with the school’s 3D printing needs all these years (and this is mainly printing student projects). And what the school “Bear” can’t handle, I print on my personal Reborn2 (it has a larger print area, sometimes this is irreplaceable).

Actually, why did I suddenly decide to remember this whole story? In 2024, Russian schools will begin to implement a new project – BASS (“Unmanned Aircraft Systems”). Within its framework, it is planned to supply a large batch of equipment (including 3D printers and a huge number of copters). Some time ago, schools were sent an approximate list of equipment, on the basis of which regional ministries should (or have already announced) announce purchases. And now I have a bad feeling that history may repeat itself, because in the “approximate list of equipment” there were again very vague formulations, which, being thoughtlessly turned into terms of reference for the purchase, will lead to the supply of equipment of terrible quality to schools. I really hope that some responsible people will see my article and draw adequate conclusions from this story without stepping on the same rake again. And schools will receive normal equipment with which they can actually work and teach children something useful (and not Russian obscene language).