A brief history of road heating. Part two

We continue to talk about the history of heated roads. If in the previous part we talked about the chemical path, then in this part we will talk about the physical path.

This method moved from the category of fantasy to the category of solvable engineering and inventive problems with the advent of central heating networks. We are talking about district central heating networks, and not individual buildings, for which central heating has worked in various variations since ancient times, if not earlier. But the thawed patches in the snow along the heating mains from the district boiler house, which appeared in the cities of the Old and New Worlds in the 1880s and 90s and in St. Petersburg in 1902, themselves suggested what to do next.

The problem here was only of an engineering nature: distributing the coolant through pipes in the road surface. It is clear that there was no point in heating the cobblestone street from below. Asphalt, still natural (bitumen) mixed with sand, occasionally appeared as a road surface in European cities, including the capital of the Russian Empire, back in the first half of the 19th century. And in 1852, the construction of a highway from Paris to the city of Perignan on the border with Spain with a length of more than 700 km, completely filled with bitumen from the Swiss deposit in Val-de-Travers, was completed.

In 1870, Belgian engineer Edouard Desmedt received a US patent103581 on “Improvements in laying asphalt or concrete sidewalks or roads”, but essentially on the recipe for modern asphalt concrete, and on the procedure for its installation. Next came a stream of American and European patents to improve this top layer of “road pavement,” which has not dried up to this day. At the turn of the 19th and 20th centuries, the replacement of paving stones with asphalt on the road surface of city streets began at an accelerated pace, and when by the end of the 2000s the number of cars began to number in the tens of thousands and grew exponentially, shock asphalting of intercity roads and then local roads began .

In principle, the technical characteristics of a grid of pipes with coolant in the asphalt concrete layer of the road surface were also clear. The theory of heating houses, including in-floor pipes, was developed by Professor Arthur Barker of University College London and published in his famous 1912 book The Theory and Practice of Heating and Ventilation, a thick tome of 752 pages with tables, graphs and formulas for calculating the pressure of steam and water in heating system pipes depending on their diameter and the desired outlet temperature, as well as in his 1907 British patent No. 28477 for a “low-temperature radiant heating” system built into the floor of a room.

All that remained was to take this system out of the building, to begin with, at least under the sidewalk at its facade, adjusting the level of “radiant energy” optimal for melting ice and snow using formulas and tables, and using the same hot water from the central heating system of the building as a coolant . And add antifreeze to it for reliability, so that the pipes do not burst if there is a failure in the system or during a sudden cold snap. But no one did this. Why? Probably because such a heating structure made of steel pipes under the asphalt was rigid, and the asphalt under the flow of traffic, including heavy vehicles, is called breathing. No one would dare to guarantee its tightness for a long time.

A replacement for steel pipes only appeared in the 1930s in the form of so-called cross-linked polyethylene (PEX), with cross-links in its macromolecules. It had indicators of flexibility and dynamic strength that were quite suitable for this purpose, and is now widely used in pipeline engineering networks. Then other types of polymers and composite materials appeared, even more suitable for water heating of road surfaces. But that was later, in the last quarter of the last century. And before World War II, no one risked money and authority to introduce such road heating.

The first such system of a fairly large area appeared in 1948 in the town of Klamath Falls, Oregon. The town was small with a population of 15,000 people, which is called provincial, but on May 5, 1945 the whole world learned about it. A 15-kilogram high-explosive bomb from a Japanese balloon fell on him and killed a woman and five children. These were the only civilian casualties in the continental United States from the drone-balloon raids that the Japanese launched from the island of Honshu from November 1944 to the end of April 1945, three hundred of which made it to America. Everyone knows what bombs the Americans responded to this with exactly three months later. In 1948, steel pipes were laid into a cement concrete pavement along a 135 m long path leading to one of Klamath Falls' geothermal wells. Typically, cement concrete is used at airfields, and the local hot underground waters have been known since the beginning of the last century.

The system served faithfully without a single repair for almost half a century, and only after the 1993 earthquake, which destroyed several buildings in Klamath Falls, was it overhauled, replacing the old iron pipes with PEX pipes. By this time, geothermal waters had already become the main coolant for water-based road heating systems around the world, since free heat from the depths of the earth’s crust allows them to be operated “at or close to operating break-even.” Not counting capital investments for their construction, of course.

The economic benefits of using thermal waters for road heating are somewhat spoiled by the fact that water with a temperature of 20 to 90 degrees Celsius comes out or is close to the surface of the earth in earthquake-prone areas at the junction of lithospheric plates; it, in fact, comes out when the plates move. In other places it is necessary to drill kilometer-long wells to access it. But since people live here, it would be a sin not to take advantage of the free warmth. Iceland is considered the standard for heating roads with thermal waters, with 32 volcanoes, 7 of which erupted in the last century, and 5 in the current one, one twice.

The drilling of wells for district heating in the capital of Iceland, Reykjavik, began in 1928. There are now more than 70 of them in the city and its environs, and since 1972, 97% of its residents have received water from hot springs. By the way, 55% of all Icelanders live here, in Reykjavik and its suburbs. Beginning in the 1980s, it became common for them to channel this water into pipes under sidewalks and garage driveways. And by the beginning of our century, on the two main shopping streets of the capital it was no longer possible to slip on trampled snow or ice, because there was none there, but there was very decent slush, which is not customary to talk about, so as not to offend the Icelanders. And the removal of liquid mud into the sewer system is another area of engineering and invention.

At the moment, the total area of the heated road network (road network) in Iceland is approximately 1.2 square meters. m, that is, if we take the average width of a street or highway as 12 m, we get about 100 km of heated roads. This is an absolute record; in other countries where there are heated roads, and such states can be counted on the fingers of two hands, their length is an order of magnitude or even two orders of magnitude less. Here's just one example. In Holland, Michigan (population 33,000 and 66 cm of snow during the winter months), the “largest heated floor in America” was built in the 8th Street business district in 1988. a road heating system, which, in the absence of geothermal sources within a radius of a couple of thousand kilometers, uses water from the cooling system of a local coal-fired thermal power plant.

In 2015, the German industrial giant Siemens received a contract from the city authorities of Holland to convert a local power plant from coal to combined cycle gas and “showed interest” in the local snow, they say, should they change the water heating of streets in the city to electric and expand its area, even to In Berlin's Kurfürstendamm (the Berlin analogue of the Parisian Champs Elysees), about 600 square meters of sidewalk are heated with electricity. But the cart, as they say, is still there. According to the German Federal Institute of Road Management, heating the asphalt on Kurfürstendamm to plus three degrees Celsius in winter requires about 3,000 kilowatt-hours of energy per square meter. As a result, “the largest heated floor in America” remained with water heating and the same area – 46,000 sq. m. m, that is, about 3 km on 8th Street and adjacent side streets in the city of Holland.

In the 1970-80s, there was a shift towards heat exchangers with closed circulation systems rather than flow ones. In 1982, Daimler-Benz engineers developed such a closed system for heating roads using underground heat, based on the fact that at a depth of 90 m the ground temperature never drops below +9 ° C. Their coolant was liquid sodium in sealed vertical pipes coated on the inside with porous absorption material. In the lower part of such a pipe, under the influence of geoheat, sodium rose upward, and under the cold roadway it gave up its heat to the asphalt concrete surface of the road and, condensing in the porous inner coating of the pipe, slowly flowed down. No adjustment was required here, such cycles followed one after another spontaneously and only when it was needed, and in the spring, when it got warmer, they stopped on their own. The system was not purely theoretical, it was built and tested in the town of Boxberg in Baden-Württemberg. In these parts, in those years, a lot of things were tested and as many as three nuclear power plants (now closed) were built. But this invention had no continuation. Perhaps the system did not work efficiently enough or its payback period seemed too long.

A more economical option was proposed by a team of road engineers from the Kuibyshev Civil Engineering Institute named after. Mikoyan and scientists from Kuibyshev State University in 1989. Their copyright certificate is now listed in patent databases under the name SU patent1482990 in Russian and English. The heat source here was not a sodium geothermal heat pump, but the heat of a domestic sewer. The coolant (which one is not specified, it could be the same sodium or cheaper options, for example, alcohol or ammonia) is located inside L-shaped pipes, coated on the inside with a porous material. The lower end of the vertical part of the pipes is immersed in waste water in the sewer pipe and is equipped with heat transfer intensifiers in the form of thickenings discretely located along the perimeter. The upper horizontal end of the pipes forms loops that transfer heat to the asphalt concrete of the road surface. There are also details like a trap valve for non-condensable gases, but in general it was the same autonomously operating system, which itself turns on in the winter and turns off in the warm seasons of the year. It is clear that it could only be used to heat the roadways of city streets, where sewerage pipes usually run. But it was much cheaper than the German one. But, like many other promising Soviet projects of the late 1980s, it was not implemented in practice either.

As for electric road heating, a laboratory model of such a system has been known since 1859 and is described in the patent application of a certain Mr. Simpson of Washington for the invention of “an improved electric heating apparatus producing heat sufficient for heating rooms, boiling water, cooking food, etc. ”, that is, simply put, an electric stove. Simpson filed an application with the patent office on December 16, 1857, and the U.S. patent25532 received for a kitchen electric stove in September 1859. By the way, his stove had a closed spiral. In the drawing in the patent it is open, but the author of the invention warns that he did this intentionally, for clarity.

The spiral lies in grooves cut in talc slate (soapstone or pottery stone, from which pottery was made in prehistoric times), and can be covered on top with tiles of the same soapstone. Let anyone argue that Simpson's electric heating system lacks at least one of the three main components of modern electric snow melting systems: a heating cable, a control unit and an activation device, as they now write in textbooks for road engineering students, then they themselves write in their dissertations, when they become engineers, and in technical reference books and popular encyclopedias.

The only thing holding this design back from scaling up to a road-based snow and ice melting system was that it was powered by a galvanic battery. And its tightness did not guarantee against melt or condensate water getting on the spiral and causing a short circuit. As for nutrition, this problem was solved at the end of the same 19th century. But a suitable heating element braid did not exist until the 1930s, when, as already mentioned, cross-linked polyethylene (PEX) was synthesized, and a little later other polymers with even more suitable properties for cable laid in asphalt.

In the second half of the 1950s, experimental sections of asphalt concrete pavement appeared, heated by low-voltage electric current. On one of them, the heating cable was even laid in an armored steel pipe. And ten years later in Western European countries there were already about 172,000 square meters. m of heated roads, which corresponds to a section of the highway about 11 km long.

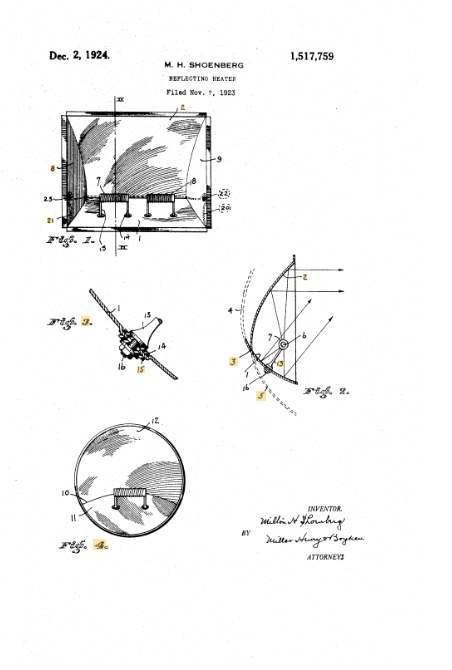

But a little earlier, in 1954, in the French city of Lille, on its main shopping street, the Neuve, electric heaters with reflectors were screwed to the facades of houses at the level of street lamps. Such electric heaters with parabolic “radiant energy” reflectors appeared in the early 1920s (see, for example, US patent1517759). Actually, they were designed to heat rooms, but then they were hung outside. Photos of men in shirts with rolled-up hands, drinking beer in the middle of winter on the street terraces of cafes, and a lady in shorts sitting on the street in a longchair, have circulated throughout the world's media, and videos shown on television news in many countries are still circulating in social networks.

Nev Street is actually quite narrow and only 170 m long, and with the wind, of course, it was blown through by the winter cold, so the reflectors did not hang on it for a long time. But this funny incident in the history of road heating, started by the municipality of Lille with the explicit goal of attracting tourists to the city during the low season, was a harbinger of new technologies for contactless heating of roads using electromagnetic waves of different frequencies.

If we return to the origins of electric road heating, then in 1959 in Liverpool, an electric cable was laid directly on top of the paving stones on a hundred-meter section of one of the main streets in the city center and filled with a 15-centimeter layer of asphalt. They could have done this a year earlier, but, as road engineers later reported to the city Committee on Roads and Improvement, they had a problem. It was urgently necessary to look for and test a special heat-resistant cable so that it would not be damaged when poured with hot asphalt and pedestrians would not be electrocuted. In addition, electricity was quite expensive. But the electric road heating system was attractive due to its ease of installation and maintenance, and the main trend in the theory and practice of road electric heating now lay in the direction of improving the heating cable. At the same time, the development of special asphalt paving equipment was underway, which could immediately form grooves for heating elements during the filling of the road surface with asphalt concrete, rather than making them separately, virtually manually.

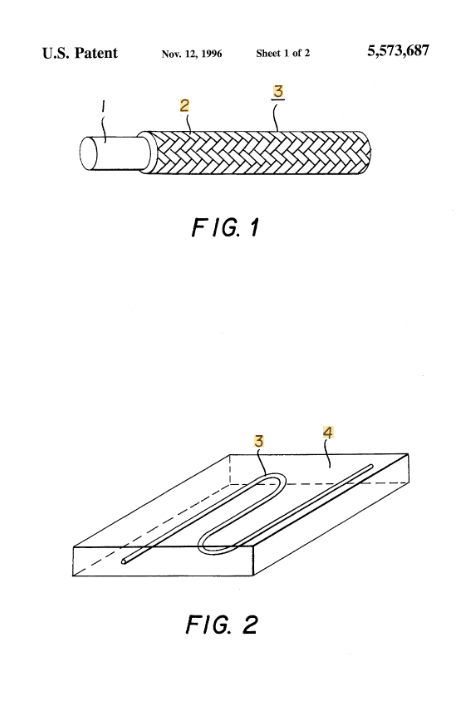

In the late 1980s, Japanese companies joined the electric road heating race, and in the 1990s, Chinese and South Korean companies, and now most patents for electric road heating are written in hieroglyphic writing in the original. Here, for example, is a relatively early patent of the Japanese chemical giant Teijin Ltd in 1994 (its American version is US5573687 1996) for “a fiber electric cable road heater that has a compressive yield strength (Lc) of not less than 1000 kg; and the outer textile structure is made of thermoplastic synthetic fiber having a melting point of at least 200°C and a fineness of one fiber of at least 1000 denier, which allows, when laying the roadway after laying road heaters, to use any type of asphalt concrete composition and any pavement laying procedure, including including at high temperatures, which in turn allows the installation of the coating to be completed within a short time.”

This is probably the end of the history of road heating technologies; then their present begins. New technologies have been added to heating roads using cables or electric mats. Experiments have shown that a coating of a thin layer of concrete mixed with graphite and steel fibers, connected to electricity, can generate heat to prevent ice formation. In practice, this technology was first implemented in China on two parking ramps, each 41 m long. Their electricity consumption was 200-300 W/sq.m. m, that is, an order of magnitude less than on the Berlin Kurfürstendamm.

Microwave heating does little to melt snow and ice. In its range (from 100 MHz to 100 GHz), energy will be absorbed by liquid water molecules (at microwave frequencies – GHz), but not by ice crystals (they react at kHz frequencies – long radio waves). But microwave heating can dramatically increase the efficiency of sand-salt mixtures, or rather their modern analogues. Induction heating was tested on asphalt concrete with steel wool fibers. We tried adding steel shavings to asphalt concrete. All of these, by the way, are Chinese developments, but so far with unclear prospects.

Nowadays “sunny roads” are popular. The top layer of their “road pavement” is an insulating layer on which lie solar panels embedded in transparent concrete. About a kilometer of such roads, which in the future, as their creators plan, will not only melt snow and ice, but also illuminate roads at night and even charge electric cars racing along them, have already been built in America, France and China. Time will tell whether they will become another Lille Rue Neuve. But if they do, then for engineering and inventive thought this is in the order of things, the main path is marked, and new breakthrough ideas will not be slow to appear on it.

Useful from Online Patent:

How to get government support for an IT company?

What benefits can you get from registering a computer program?

More content about the field of intellectual property in our Telegram channel