Waste methane & amp; 3D printing and metal

Scientists have improved the technology of 3D printing from aluminum, having achieved an increase in the hardness of parts for aerospace by one and a half times. The nanocarbon additive to aluminum powder developed by them, obtained from the products of associated petroleum gas processing, will improve the quality of 3D printed aerospace composites. The research results are published in the international scientific Composites Communications Magazine

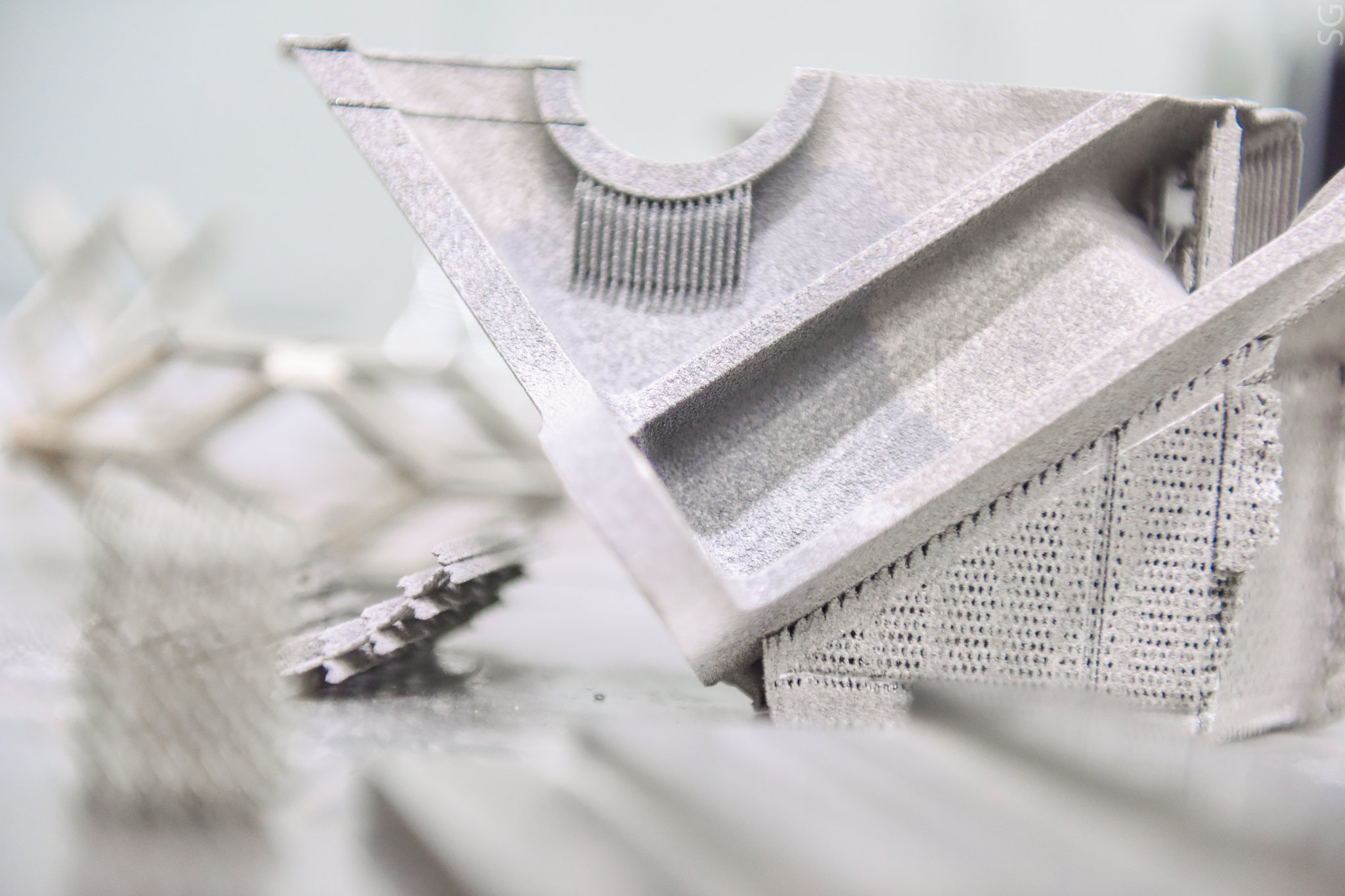

Today, the main field of application for aluminum 3D printing is the creation of high-tech parts for the aviation and space industries. The presence of even the slightest defects in printed structures is critical to the safety of the technology being created. According to NUST MISIS scientists, the main risk of such defects is high material porositycaused, inter alia, by the qualities of the original aluminum powder.

To ensure a uniform and dense microstructure of printed products, scientists from the MISIS Catalis Lab proposed adding carbon nanofibers to the aluminum powder. The use of this modifying additive allows to ensure low porosity of the material and increase its hardness. one and a half times

“Improving the properties of printing powder allows changing its chemical and phase composition by introducing additional components into the main matrix. In particular, carbon nanofibers have high thermal conductivity, which helps to minimize temperature gradients between printed layers during the synthesis of products, at the stage of selective laser melting. this microstructure of the material can be almost completely eliminated from inhomogeneities, “ – said the head of the laboratory, professor at NUST MISIS, Doctor of Technical Sciences. Alexander Gromov

The technology for the synthesis of nanocarbon additives developed by the research team includes the methods of chemical deposition, ultrasonic treatment and IR heat treatment.

It is important that the carbon nanofibers used are by-product of associated petroleum gas processing. During its catalytic decomposition, carbon accumulates in the form of nanofibers on dispersed metal particles of the catalyst. Usually, at present, associated gases are simply burnt in the fields, which harms the environment. Therefore, the application of the new method also has a serious ecological significance, – said Professor Gromov.

The study was carried out jointly with specialists from the Institute of Catalysis, SB RAS. In the future, the research team plans to determine the optimal conditions for selective laser melting of new composite powders, as well as to develop a technology for post-processing and industrial use of synthesized products.