Overview of Solutionix D500 and D700 3D Scanners

Hello! In today’s review, we will introduce you to the Solutionix D-Series Dental 3D Scanners: Models D500 and D700.

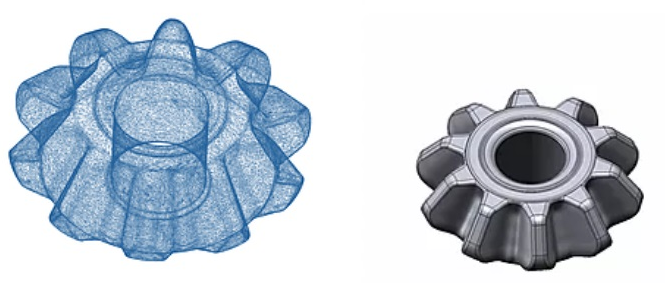

These professional devices are designed for scanning medium-sized objects with complex geometry, accurate recognition of small parts. The resulting models are highly detailed. D500 and D700 differ only in the resolution of working cameras. The letter D in the name of the series means Dental – they are primarily intended for dentists, but not only.

Specifications and detailed information on the Solutionix 3D scanner line are presented below.

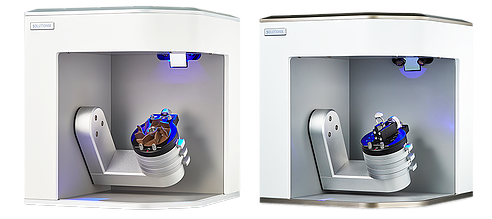

Solutionix D500 Solutionix D700

Source: solutionix.com

Content

- general information

- Specifications

- Description

- Workspace

- Color rendering and texture capture

- Software package

- Calibration

- Scanning

- Data processing

- Advantages and disadvantages

- Scan Examples

- Areas of use

- Quality control

- Reverse engineering

- 3D Scanning

- Total

general information

Designed for scanning small objects with high accuracy, Solutionix D-Series are known and in demand in many areas:

- jewelry making;

- Dentistry

- design

- in museums and research centers for the study and restoration of cultural property.

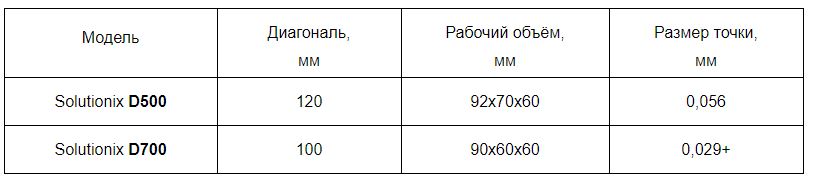

Specifications

As can be seen from the table, the only difference between the models of the line among themselves is in the parameters of the working chambers.

Description

Source: solutionix.com

Solutionix D500 and D700 3D scanners are compact in size and can easily be placed on the table in the laboratory, dentist’s office or any place convenient for the user.

The main structural elements of the scanners are the body, the turntable, 2 working cameras and the Blue LED backlight projector. The desktop rotates scanned objects from different angles. A ray of blue light bounces off objects and enters camera lenses. This technology provides high detail and accuracy of finished models.

All processes are automated, the control is simple and clear, which guarantees a quick and accurate result when using D-series scanners.

Workspace

Source: solutionix.com

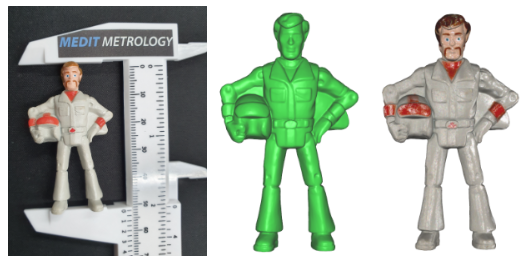

Color rendering and texture capture

Source: solutionix.com

Solutionix D500 and D700 accurately convey the shape and texture of objects. High resolution of the obtained data allows its use in many fields: for quality control, in reverse engineering, computer modeling and animation, and other fields. Of course, only when working with small objects (like the car model in the picture above), which is due to the small working volume.

Software package

Source: facebook.com

Solutionix D500 and D700 are powered by Solutionix ezScan. The program is used to calibrate devices, as well as process scan data: stitch images taken from different sides at different angles.

Calibration

Source: solutionix.com

Calibration is fully automatic, to start work you just need to run the program.

Scanning

Source: facebook.com

After installing the object on the desktop and selecting a program, scanning and model creation begin. The processes are fully automated and do not require user participation.

Source: solutionix.com

Depending on the features of the scanned objects, various algorithms can be used in the work. The software implies the ability for the user to select their own scan route.

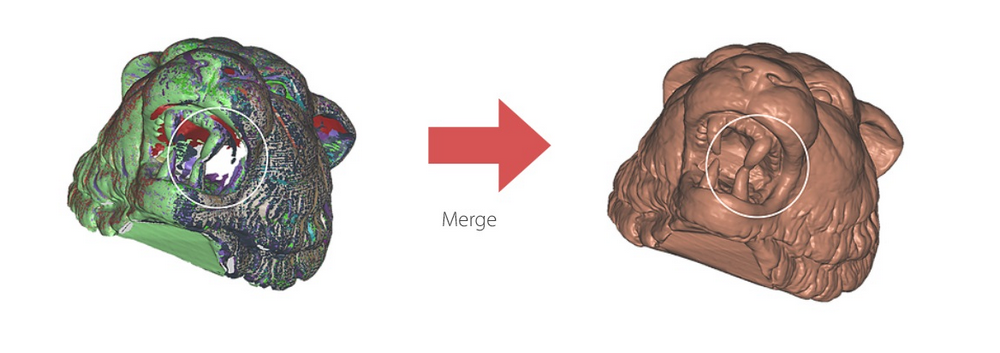

Data processing

Source: solutionix.com

When scanning objects with narrow, deep holes and indentations, difficulties often arise. The Data Connect feature solves this problem by filling in the voids during processing.

Advantages and disadvantages

Strengths of Solutionix D500 and D700:

- small size, the ability to place on any convenient surface;

- comfort when shooting small items;

- full automation of processes, increasing work productivity;

- full color scanning in high resolution.

Weaknesses:

- when working with transparent objects or objects with shiny and black surfaces, it is necessary to use matting agents;

- very small scan area.

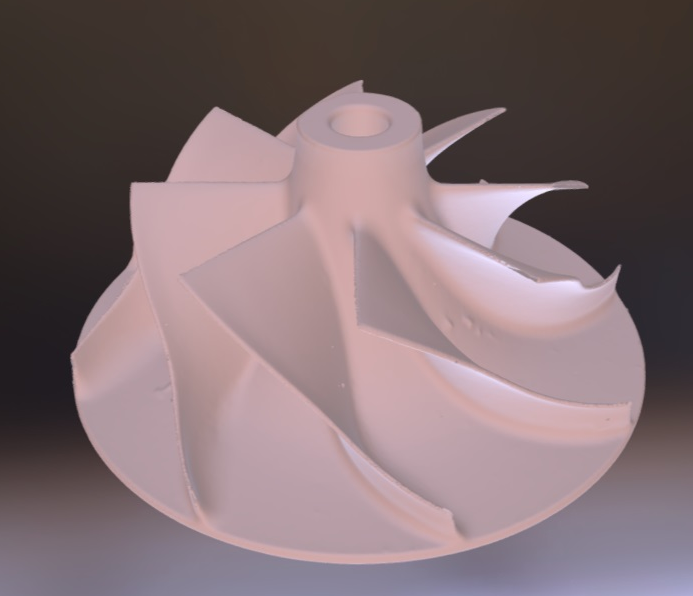

Scan Samples

Source: facebook.com

Source: sketchfab.com

Application

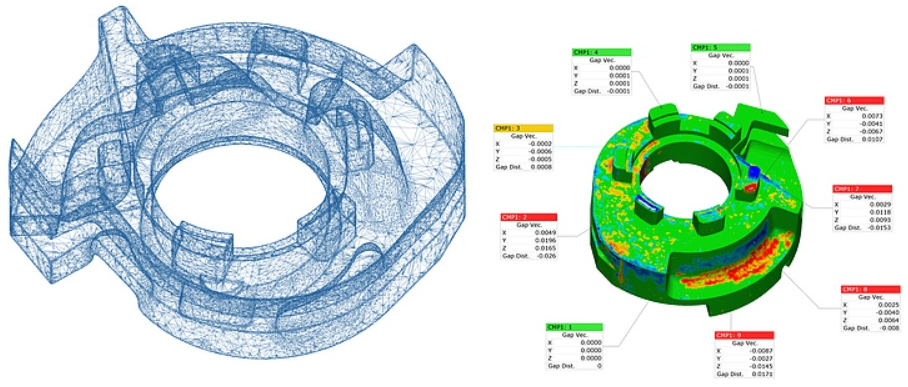

Quality checking

The software allows you to compare scan results with a basic CAD model. After comparing the data, a color deviation map is created.

Source: solutionix.com

Reverse engineering

Source: solutionix.com

It is used in 3D-modeling, designing, manufacturing equipment, restyling and other areas. D-500 and D-700 scan small objects of arbitrary geometry with data transformation into computer-aided design systems formats.

3D Scanning

Source: facebook.com

Creating seamless patterns for subsequent three-dimensional printing in the entertainment industry, medicine, rapid prototyping, manufacturing and other fields.

Total

Solutionix D500 and D700 3D scanners are an excellent solution for creating models of small-sized objects with complex geometric shapes. Modern illumination technologies provide high accuracy in transmitting the shape, color and texture of objects. Full automation of scanning and data processing increases productivity in any field of use of devices.

Buy Solutionix D500 or D700 at Top 3D Shop, from the official representative of the manufacturer in Russia, and you will receive professional equipment with an official guarantee, after-sales service and information support.