Motorcycle made using SLS 3D printing

Workshop in the basement of the AGH school building.

E-moto AGH, a team of students from the Polish Mining and Metallurgical Academy named after Stanislava Staszica (hereinafter referred to as AGH), designed and built an electric off-road motorcycle. Students not only wanted to prove the advantage of alternative energy sources, they also learned to apply the latest solutions, such as the Sinterit Lisa Pro desktop SLS 3D printer. Basically, the motorcycle was created in the laboratory of the academy.

“We spend most of our time in the workshop,” says team leader David Senko. – Our project is the creation of electric motorcycles. Two motorcycles are ready: eight and thirty kilowatts. ”

The E-moto AGH team builds its motorcycles from start to finish. Many parts are made by hand, for example, using vacuum molding or machining on machines. The remaining parts are printed on 3D printers. Students use several printers, mostly of the FDM type. But there was a special task for which the selective laser sintering technology SLS (Selective Laser Sintering) was applied.

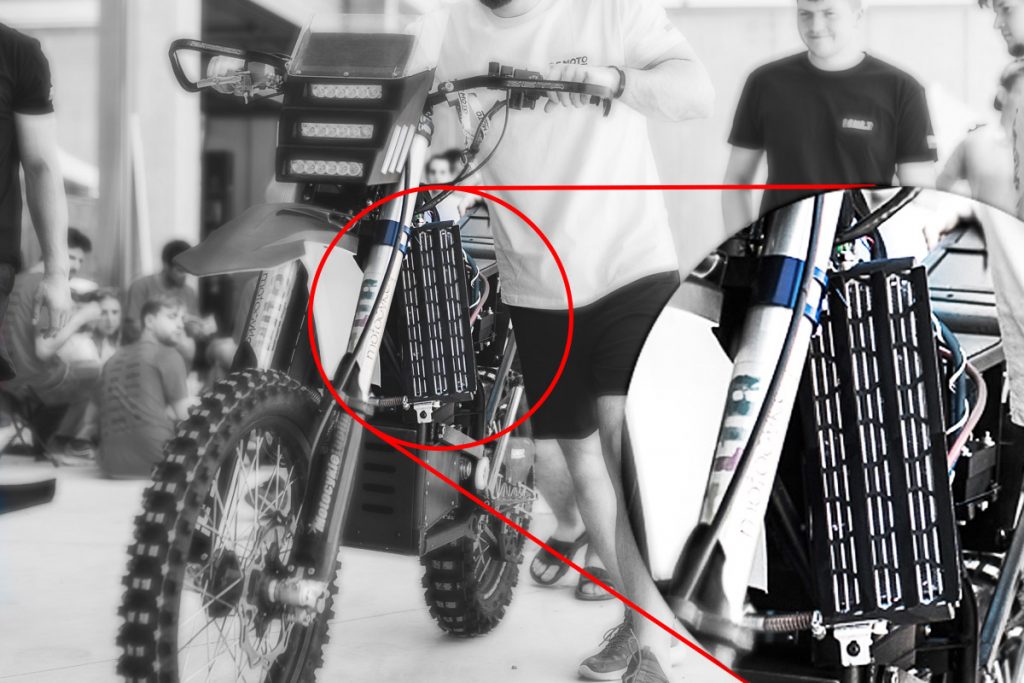

“We needed to print a radiator case, and SLS technology is best suited for this because printouts are durable and some parameters are more predictable compared to FDM technology,” says Jakub Sobanski. “It is also very important that a wide range of powders is used for SLS.”

Photo: Andrzej Rusinovsky / KSAF

The E-moto AGH team, as already mentioned, used the Sinterit Lisa Pro 3D desktop printer for printing the radiator case. One of the advantages of SLS technology is that it allows you to print very complex designs. Students printed details with a honeycomb structure. The air deflectors were designed so that the radiator does not become clogged with dirt and that gravel does not damage it.

“The printout came out so good and resilient that although the motorcycle fell several times, the part was not damaged,” says Yakub Sobansky.

How affordable is SLS 3D printing?

There are two types of 3D SLS printers on the market: industrial and desktop. They differ in the volume of the printing chamber, the degree of automation of the process and the range of materials.

Desktops are great for research, rapid prototyping, and even small batch production. The huge potential of SLS lies in new materials with individually selected properties, among which there can be conductivity, heat resistance, water-repellent properties – the list goes on and on.

And most importantly, desktop SLS-3D printers are several times cheaper than industrial printers.

AGH students learned how to use the most advanced 3D printing technology, such as selective laser sintering, as efficiently as possible and printed functional parts for motorcycles on the Sinterit Lisa Pro, with which they participated in the Smart Moto Challenge Championship in Spain.

“The choice of printer was also associated with the choice of print material. When choosing a Sinterit Lisa Pro 3D printer, we took into account the maximum temperature of the coolant, which is 60 degrees Celsius. PA12 powder, the main printing material for SLS 3D printers, came up very well for our project, ”added Jakub Sobanski.

SLS 3D printers are ideal for use in research and development. SLS technology goes far beyond prototyping, even functional ones. The quality and durability of printouts are so good that, under certain circumstances, with the help of SLS 3D printers, you can successfully print the final product.

Photo: Andrzej Rusinovsky / KSAF

Smart Moto Challenge Championship in Barcelona

The E-moto AGH team installed 3D-printed radiator cases on their motorcycles and went with them to the Smart Moto Challenge.

The international championship has been held for eight years in a row. Student teams from different countries come there. Each team, for a maximum of three years, designs and manufactures its own electric motorcycle. First, the commission evaluates the technical documentation and business plan of each project.

Then they check how the motorcycle tolerates rain, how the headlights and brakes work, etc.

In conclusion, dynamic tests are carried out: they evaluate the acceleration, energy consumption of the batteries. Motorcycles participate in slalom, cross-country, endurance race.

Both motorcycles built by the E-Moto AGH team passed all the tests. Students are now developing a new version for next year’s championship.

Prototyping for the automotive industry requires technologies that guarantee high fidelity and durability. That is why selective laser sintering is chosen by many research groups and manufacturing companies. This technology is reliable and is now available for small and medium-sized businesses, universities and schools.

This is especially important for technical universities that train future engineers and inventors. If the workshops of universities have the best-in-class tools and machines, students will be able to learn and master the latest and most advanced technologies.

Read more about 3D printing in blog post Top 3D Shop.