Hydrogen is the head of everything: how energy is generated from plastic debris for a Japanese hotel

Plastic garbage is transformed from a nightmare of any self-respecting environmentally conscious citizen into one of the resources for the transition to a hydrogen economy. Recently, a hotel was opened in the Japanese industrial city of Kawasaki, the energy for which comes from recycled bottles, bags and even toothbrushes used by guests. We tell how “Japanese Chelyabinsk” came to this practice and what role Toshiba played in this.

Different types of plastics were invented in the 19th century. In 1862, the British Alexander Parks tried to create a cheap substitute for ivory – the main material of billiard balls. Having mixed nitrocellulose, camphor and alcohol, he heated the resulting substance, and then cooled. So Parkesin appeared – the first semi-synthetic plastic. In subsequent years, other types of plastics were invented, but the era of their commercial success began much later – in the middle of the 20th century.

In 1967, the movie “Graduate” was released on the screens in the United States. In one scene, businessman McGuire calls for a confidential conversation with a college graduate Ben (played by young Dustin Hoffman) and says: “I want to tell you one word. Only one. Plastic. Plastic has a great future. Think about it”. The dialogue later entered the top 100 cinema quotes according to the American Film Institute. Source: wsinful / YouTube

Indeed, the era of plastic began in the second half of the 20th century – at the same time as the rapid growth of mass consumption. According to The Economist magazine, 6.3 billion tons of plastic have been produced on the planet since the 1950s, of which only 9% were recycled and 12% recycled. Where is the rest?

And the rest is either buried in the ground, or drifts in the oceans. And there is no improvement yet: in the 2010s, 300-400 million tons of plastic were produced annually. The UN Environment Program (UNEP) experts noted in 2014: “Unfortunately, the market economy has failed to take into account external environmental factors, including the social, environmental and economic impact of marine plastic. The current “plastic economy” is characterized as a linear model of production and consumption, in which an unpredictable amount of waste is generated, which leads to its complete inefficiency. ”

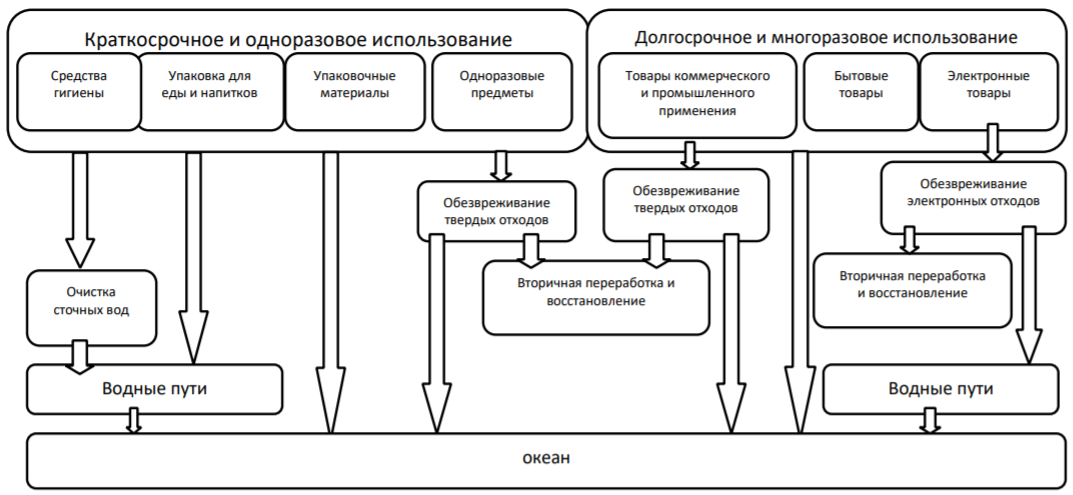

The main sources and ways of plastic pollution of the oceans. It is noteworthy that 40% of plastic waste is packaging. Source: “Plastic debris and microplastics in the oceans. Global warning and research, call to action and policy change guide. ” UNEP, 2016, Nairobi / UNEP (2016).

The largest accumulations of plastic are found in coastal waters, especially in regions with a high population density, as well as in areas of intensive fishing and developed coastal tourism. One of them is Japan, and in this country the fight against plastic waste has been going on for a long time and not without result. According to the UN, in the country of the rising sun, the total utilization rate of plastic is 82%. But the Japanese did not achieve this right away.

Japanese Chelyabinsk: how Kawasaki turned into an eco-city

After World War II, large industrial zones formed in Japan, which ensured rapid economic growth. The flip side of the coin was the growing environmental problems that not only harmed nature, but also claimed lives. For example, in 1950-1960. Outbreaks of Minamata disease (fatal paralysis) caused by the discharge of inorganic mercury into rivers by the factories were repeatedly recorded.

The center of development of Japanese industry (and related environmental problems) was the coastal industrial zone of Kawasaki – about 50 enterprises in an area of 100 hectares. In the 1970-1980s. a powerful environmental movement was born here, which forced local authorities to act. In 1970, the city signed air pollution prevention agreements with 39 factories. In 1972, a center for monitoring harmful emissions was established. In 1978, automated nitrogen oxide output control was introduced at 32 of the largest plants.

At the same time, a waste management system was developed, involving the processing of most of the garbage.

It took more than 50 years to create and debug a waste management system in Kawasaki City. Source: Kawasaki Environmental Research Institute

In 1997, the city of Kawasaki was chosen by the Japanese government as a “training ground” for the implementation of the “Ecocities” project. The state program provided for subsidies of $ 600 million for 24 eco-cities, as well as direct investment in 60 projects in these cities for $ 1.6 billion.

Moreover, Kawasaki immediately received “specialization” in the reuse of waste. By 2004, an industrial park (Kawasaki Zero-Emission Industrial Park) was built here, with 15 enterprises included in waste processing. The enterprises of the local industrial zone are gradually merging into a single network of consumption and distribution of recyclables. Its part will be the urban hydrogen distribution network. How does she work?

Fire, water and pipe: how plastic turns into energy

In 2015, Kawasaki developed the Kawasaki Hydrogen Strategy Towards Achieving a Hydrogen Society. As part of it, it is planned to organize hydrogen supply chains (including from abroad) in Kawasaki, where this gas will be processed into energy using Toshiba systems.

In 2017, the Toshiba autonomous power station H2One already began to supply electricity and heat to the Musashi-Mizonokuchi railway station in Kawasaki, which we talked about earlier on Habré. The station generates hydrogen from water by electrolysis, and the built-in solar battery provides power for this process. Then, hydrogen is converted into energy for the station.

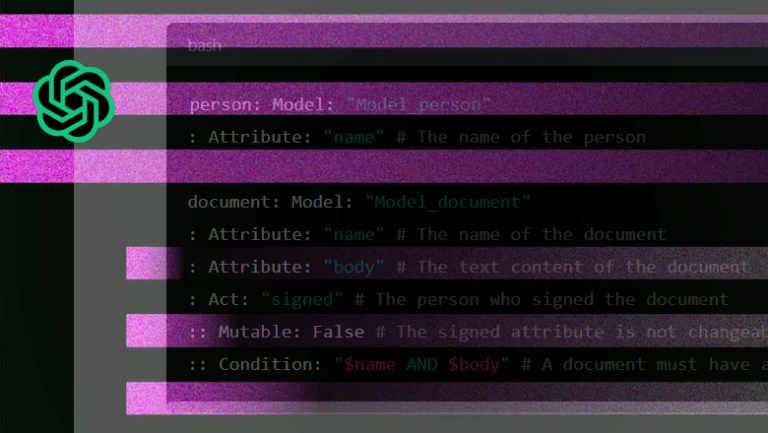

But hydrogen can be obtained not only from water, but also from recycled plastic. In 2018, Toshiba equipped the hotel KAWASAKI KING SKYFRONT Tokyu REI hotel installing H2Rex. Unlike H2One, it does not produce hydrogen, but receives it from an external source, then converting the gas into electricity and heat for the hotel.

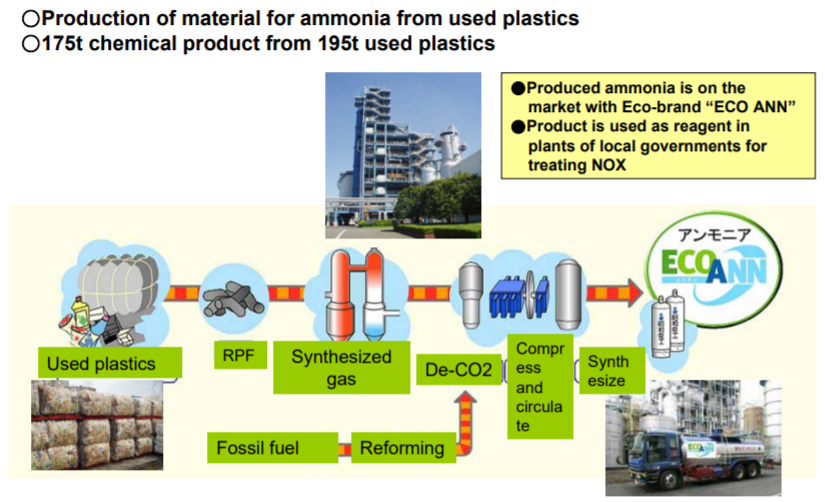

How does plastic turn into hydrogen? This happens at the factory of our hydrogen strategy partner company Showa Denko K.K.. Plastic waste comes here from the city’s garbage collection system, including from the coastal area of Kawasaki, through an open bidding process. Here, the plastic used is decomposed by thermal gasification. In this case, the organic part of the waste is converted to hydrogen, and carbon monoxide is also released. Carbon monoxide from this process is used to produce carbon-based products, such as dry ice. Hydrogen is used to produce ammonia, goes to hydrogen gas stations, and is also used to generate electricity in a hotel.

From 195 tons of plastic waste, 175 tons of ammonia can be produced. Source: Showa Denko

From Showa Denko’s plant, hydrogen flows into a pipeline that leads to a hotel located 5km from the plant. The pipeline provides a stable gas supply and does not emit CO2 during transportation, such as, for example, cars with internal combustion engines. Using a network of such pipelines, it is possible to reduce the total carbon dioxide emissions by about 80% in the entire chain compared to the existing method.

Gas flows from the pipeline to H2Rex, Toshiba’s hydrogen generator. Its fuel cells generate electricity through electrochemical reactions between the produced hydrogen and oxygen from the atmosphere. The result is electricity and heat.

H2Rex is harmless to nature. The only by-product of production is water, which is used in the operation of the generator. By the way, the hotel’s plastic waste (toothbrushes, packaging, disposable tableware) is delivered directly to the Showa Denko factory. Source: Toshiba Energy

The hydrogen utilization ratio in this case reaches 96%. In addition, the heat generated by fuel cells can be used to heat water or heat.

H2Rex, unlike conventional power plants (for example, turbine generators that turn heat into steam, which drives a turbine), does not convert thermal energy into kinetic energy, but generates it using an electrochemical reaction of hydrogen and atmospheric oxygen. Source: Toshiba Energy

In addition, the Toshiba fuel cell structure eliminates the need for an external humidifier – the water generated by the generator is used for this.

Another feature is the low starting temperature (60-70 degrees) of solid polymer fuel cells that are used in H2Rex. Due to this, they do not need to be heated very much to generate energy, which means that the installation can be quickly started and stopped during the day. Also, these elements are easy to adjust to a given load, which makes them convenient to use in industries with unstable energy consumption (for example, in the service sector, where there are daytime peak loads and nightly “calm”).

How much energy does H2Rex give? For one year, one installation can provide electricity to 100 households (700.8 thousand kW⋅h) or heat water for 12.1 thousand bathtubs (24.2 million liters of warm water).

Further everywhere: where else will hydrogen energy be produced and used?

By 2050, 20% of electricity in Japan will be generated from hydrogen. Also, the Land of the Rising Sun will need about 80 tankers – they will transport hydrogen in liquid form. Japanese corporations have already begun building a global network for the production and supply of hydrogen as an energy source. In 2019, a Japanese company established a hydrogen terminal at Hastings (Victoria, Australia). In addition to meeting local fuel needs, hydrogen will be converted into liquid, poured into tankers and sent to various countries, including Japan.

I wonder what will happen to oil prices in 2050?