How to get a thermoelectric 7 times faster

Thermoelectrics – a special class of materials with which you can directly convert heat into electricity, bypassing the stage of conversion of thermal energy into mechanical energy, as in conventional thermal power plants. On the basis of thermoelectric materials, it is possible to create devices of a new generation of energy. For example, it may be a recuperator, allowing the use of waste heat from the exhaust system of the car to reduce fuel consumption.

The key problem is to find the optimal composition and to obtain thermoelectrics themselves, which would be effective and resistant to high temperatures of the order of 600 – 900 ° C, would not degrade or oxidize during severe operating conditions.

Scientists of NUST “MISiS” have developed an ultrafast method for producing thermoelectric material that can directly convert heat into electricity. The compound based on complex metal oxide was obtained 7 times faster than in all previously presented world experiments. The method used in this work opens up prospects for the industrial production of powders of thermoelectric materials and the creation of devices based on them, which, for example, can simultaneously charge gadgets and heat rooms.

The staff of the REC of energy efficiency of NUST “MISiS” actively explores thermoelectric materials based on complex metal oxides, in particular, compounds based on bismuth, copper and selenium. It shows good performance characteristics as an energy converter, while being stable to high temperatures and not subject to oxidation, which means it can operate reliably and for a long time.

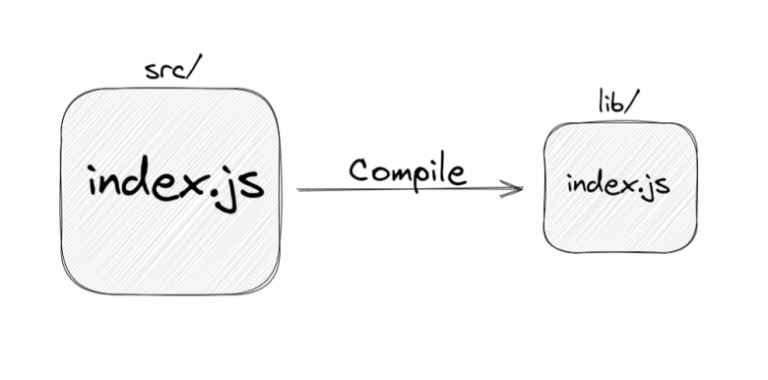

Of course, there is a significant minus – the material is difficult to obtain by the classical method, the so-called solid-phase synthesis. The mixture of the necessary starting components is sealed in a sealed quartz ampoule and placed in an oven, where the components are sintered for several days at temperatures of 300 – 700 ° C until a finished thermoelectric material is obtained. However, the resources expended in such a procedure make the method unprofitable for industrial use.

In a series of experiments, scientists of NUST “MISiS” found an alternative – this is mechanical fusion in a high-energy planetary mill, a common device for fine grinding of materials, analogues of which are found in modern plants.

During the experiments, powders of the starting materials — bismuth oxide, pure bismuth, copper, and selenium — were loaded into a planetary mill and intensive mechanical action was applied without high temperatures. The result was a homogeneous powder of the chemical composition BiCuSeO, that is, a fully synthesized material with the desired characteristics.

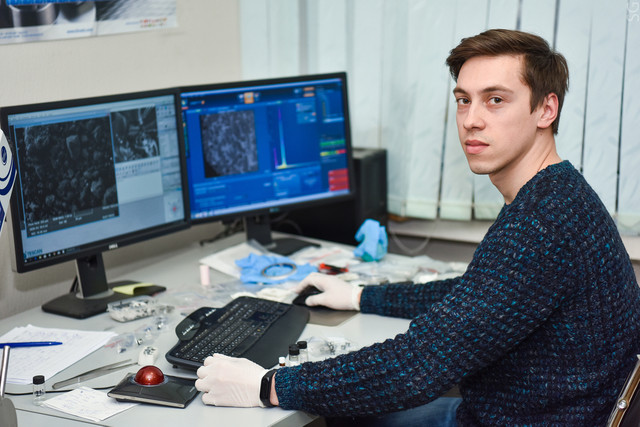

“In the finale of a whole series of experiments, we were able to find the optimal combination of the modes of speed and time of mechanical alloying, which allowed us to obtain BiCuSeO powder in record time – about 60 minutes, despite the fact that all the world analogues of such experiments in the best case allowed us to carry out synthesis in 7- 13 hours, ”says one of the authors of the work, an engineer at the REC of energy efficiency, Ph.D. Andrey Novitsky.

The simplicity of the method and the achieved speed of obtaining the material, according to scientists, will allow to scale the technology in modern chemical industries.

One of the possible devices that can be created on the basis of the obtained thermoelectric material is a universal 3-in-1 compact furnace for use in the country, in the forest, in the taiga, and other places where access to electricity and heat is difficult. This is a small stove that can be heated with wood, heat the room, serve as a stove for cooking and at the same time generate electricity with a capacity of about 50 watts – enough to charge all personal gadgets.

Currently, the team is working on adapting technology for specific production.

This work was supported by a grant from the Russian Science Foundation and published in an international scientific journal. Material letters.