how to free the operator from manual labor without breaking anything

In everyday life, we often use automatic sequences (AS), but we don’t even think about it. Because it usually goes away quickly and without a wow effect. But it’s a completely different matter in production, or when launching rockets with a bunch of orbiting satellites on board, or in a movie.

But let’s get back to reality and consider the use of AP in production. My name is Konstantin Semakov, at Severstal I create and set up automatic sequences for units. I want to share my experience: how we create automatic sequences and configure them, find errors and speed up the operation of equipment.

A few words about automatic sequences

AP accelerate production processes, reduce the likelihood of human error, allow operators to get rid of routine and only control the process. In fact, this is a program that runs on industrial equipment controllers. She sends commands to the mechanisms, receives feedback from them and decides which step to take next.

In the article I will talk specifically about creating and configuring AP, but I will not focus on programming them. I understand that for the design of an AP, it is necessary to take into account the principles of operation of a particular equipment, its capabilities and limitations. But within the framework of this article, I will not dive deeply into this, because this is a topic for a separate post.

Creator Mode: How Automatic Sequences Appear

The creation of an AP is a complex and time-consuming process. To create an automatic sequence, you need to go through several steps.

Develop structure… Perhaps the most interesting stage, because during the development of the structure, you need to understand well the process to be automated. It is necessary to study the equipment, the stages of the process and talk with the operators who have been manually controlling this process for more than a year. You need to put the whole picture in your head, understand how this can be automated, and perhaps immediately look for bottlenecks for optimizations.

But it’s okay if the first time you get not the most optimal solution. Some APs take years to perfect. Others have to be constantly redone due to changes in the technological process.

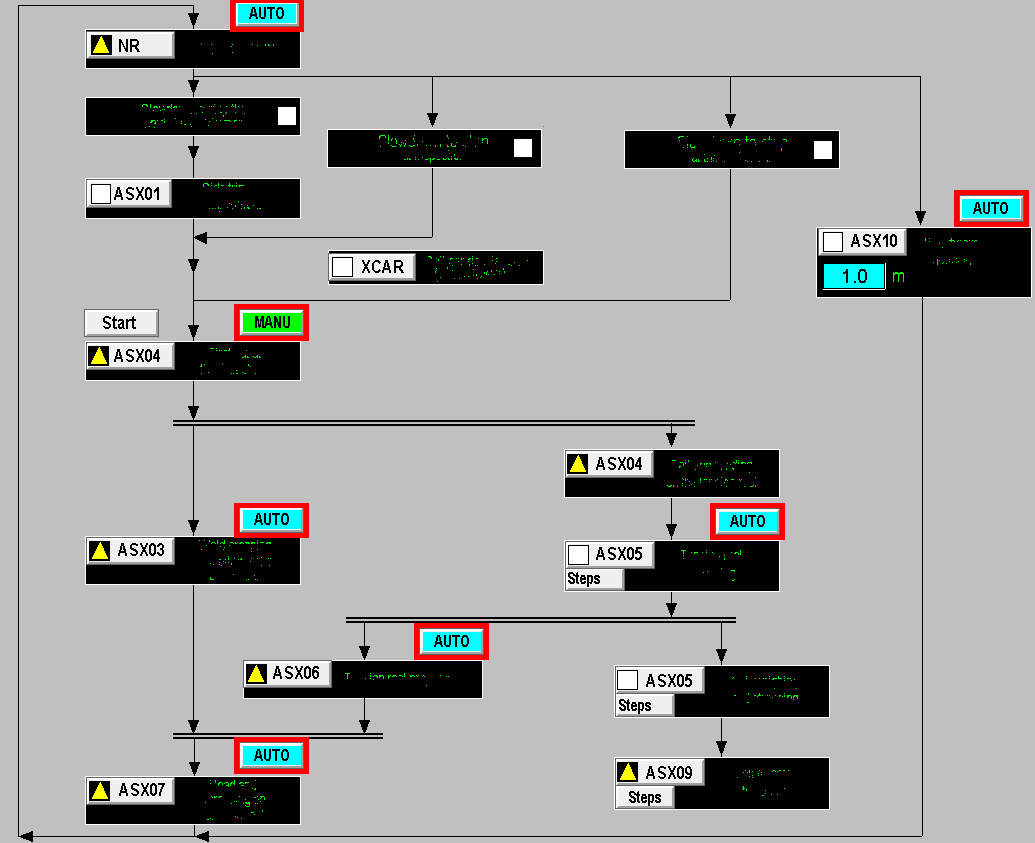

For example, this is how the structure of the AP might look like. We cannot show specific labels and node names, but this is sufficient for a general understanding of the possible structure.

Choose a controller… You need to choose the right controller so that it has the necessary capabilities and sufficient power. Usually, when choosing, several criteria are taken into account:

-

quality and reliability;

-

equipment manufacturer preferences;

-

the total amount of input and output information (network exchanges with other controllers, sensors, actuators);

-

the estimated scope of the program;

-

allowable cycle time, when controlling transient processes.

Consider equipment feedback… All mechanisms involved in the accident must be equipped with sensors. This will allow you to receive information about the condition of the equipment, the position of individual mechanisms, etc. Without this, the AP will act like a blind kitten: perform the specified actions, regardless of the current situation.

I also recommend saving error logs for each mechanism and setting up the visualization system for these logs. Subsequently, this will help to quickly understand the problems that will surely be.

Define launch conditions… It is necessary to define a list of initial conditions, without which the UA will not start. This is necessary in order for the AP to work taking into account the current situation. Here are some examples of such conditions:

-

the product is at the starting point;

-

all mechanisms are in the right position;

-

the technologist’s task is correctly formed;

-

other UAs are not executed, which should not work in parallel.

Define persistent conditions… These are conditions that must remain unchanged throughout the entire work of the AP. For example, you need to make sure that neighboring objects or mechanisms do not interfere with the operation. We check the readiness of automation equipment and mechanisms.

Think over an emergency stop… This stage must be taken into account in every process. The main task of an emergency stop is to preserve the health and life of people. The secondary task is to preserve the equipment and the product. You can endlessly work on the emergency stop logic.

As a rule, during an emergency stop, the equipment is completely immobilized so as not to cause further damage. At the same time, all subsequent accidents must know that an emergency stop has occurred and not start, otherwise the scale of the accident may increase significantly.

Create steps… The sequence consists of steps, each step sends appropriate commands to the mechanisms. Steps can be managerial and structural.

-

Control steps perform direct actions: open a valve, move a product, or turn off a pump.

-

Structural steps split the sequence into parallel branches or merge them into one. When creating parallel branches, it is necessary to take into account the power of the power plants from which the equipment is powered so that there is no overload of the power plant (for example, a compressor, a hydroelectric station or an electrical installation).

A step is considered completed when feedback is received from the sensors. There are APs in which steps are considered completed simply after a certain amount of time. I do not recommend doing this, because in the end it will fail: the workpiece will not have time to be transported to the equipment, or the previous process will simply take longer than usual.

At the same time, you need to set timeouts for waiting for feedback. If the step is not completed within a reasonable time, you need to stop the accident and notify the operator of the abnormal situation.

Create two launch modes… There are two options for starting the AP: automatic and manual. In automatic mode, the trigger is initiated by events or commands from other AP; in manual – operator’s command. But in any case, before starting, you need to check the initial and constant conditions, which I mentioned above.

Also, regardless of the starting option, it is necessary to provide for switching to manual operation. This will allow the process to continue if errors are detected during the operation of the AP.

Determine how to stop… There are several ways to shutdown the UA:

-

The command “STOP” is created, all steps of the sequence are reset, and the mechanisms remain in the same position. This is generally how the emergency stop works.

-

The command “STOP” is created, all steps of the sequence are reset, after which a new automatic program is started, which returns all mechanisms to the initial position.

-

The sequence ends when all steps have been completed and the goal has been achieved. This is a standard shutdown of the AP.

But after the creation of the AP, the work on it does not end. First, the production process may change, and the AP will have to be modernized or completely rewritten. Secondly, errors and shortcomings may emerge that could not be foreseen at the very beginning. Thirdly, there is always a wide field for process optimization. I’ll tell you about each case in more detail using examples from my experience.

Manufacturing process change

The customer decided to replace the old roller welding machine with a new laser one. To integrate the new installation into the process, it was necessary to teach it to “be friends” with the rest of the equipment: to coordinate seven internal APs with five external ones and provide for about a hundred interlocks.

We were engaged in this work together with the specialists of the manufacturing company. They knew the specifics of their equipment, and we knew ours.

The setup process was not without surprises. For example, the AP of the unit was waiting for permission to form a loop on the event “Front clamp closed”. But the event was formed due to the absence of signals from the sensors of the open position of the clamp. As a result, the metal strip began to move in the not yet fully closed clamp. We did not immediately find the reason.

Another problem is that the first seam welded in the automatic cycle broke while trying to transport for inspection. The new welding machine required twice as much strip stock in the loops for welding. And the sampling of these loops in the process of transport led to a rupture in the seam area. As a result, we created a new step of the AP “Seam transport”, in which the hinges were removed.

Find and fix bugs

In our production there is a technological operation “Removing a roll from a reel”. For its implementation, the table is pressed against the roll with a certain force and duration, depending on the weight of the roll. This is necessary so that the table fixes the load and does not leave from under the reel without a roll. In manual mode, this operation is difficult to perform without mistakes and “loud conversations with oneself”, but under the control of the AP it becomes like a dance.

Only this AP itself did not measure the weight of the roll, but received it as input from another sequence, and the other sequence did not store it due to an error in the code. In the end, it turned out that only heavy rolls were automatically removed, because they were pressed with the correct strength and duration. Lighter rolls had to be removed manually, and this greatly slowed down the process.

It would seem a simple mistake, but we spent several months looking for the reason. Therefore, once again I want to focus on the fact that all the necessary parameters and signals must be recorded in the log. Then it will greatly simplify your life.

Optimization and acceleration

Even when the AP is working as intended, there is plenty of room for optimization. For example, if you understand what steps can be performed in parallel, you can cut a few seconds in the processing of each item. It seems that this is not enough, but even within one working day, it allows us to produce more products. Here’s an example.

A welding machine is installed in the workshop, which welds two rolls of metal into one for continuous operation of the sheet galvanizing unit. During welding, the ends of the rolls are fixed by the pressure rollers of the unit and the clamps of the welding machine. When the welding machine completes the operation, it returns to its original position and releases the strip. It then sends a command to the aggregate, which allows the lane to be transported. The pressure rollers are lifted, and only then the metal strip begins to move into the central section of the galvanizing unit.

We have paralleled these processes. That is, now the pressure rollers and clamps of the welding machine are spread simultaneously, and after checking the performance of these operations, the AP issues a command to transport the metal. As a result, the strip began to loosen faster, we shortened the welding cycle by 2.5 seconds.

And sometimes, to search for optimizations, you can simply talk to operators who have been working with equipment for a long time. Their attentiveness is amazing – they can notice a delay of 0.3 seconds, while the whole process takes about 9 seconds.

In conclusion, I will not say again that automatic sequences simplify the work of operators, speed up production and reduce waste. It’s obvious. I want to focus on something else. Creating automatic sequences is not just aggregate work as it might seem. In addition to knowing the equipment, you also need to be able to understand production processes, communicate with people and find bottlenecks for possible optimizations.

Do you have experience in creating and configuring automatic sequences? Share your stories.