Electric highway testing in Germany

In theory, an electrified highway is the most efficient way to get rid of truck exhaust. Political problems hinder this.

Wires above the road provide the trucks with electricity on a five-kilometer stretch of road south of Frankfurt. This allows you to test the idea of electric highways in practice and real trucks.

On the highway south of Frankfurt, Thomas Schmeider rebuilt his paint-laden Scania truck in the far right lane. Then he flipped a switch that you won’t find on most truck dashboards.

On the roof of the truck, a device similar to a clothes dryer began to unfold, on top of which there was something like a sled. And while Schmeider continued to drive the truck, the monitor could see how the metal skids lifted and touched the wires running over the strip.

The cockpit became very quiet, the diesel engine stopped and the electric motors started up instead. The truck remained a truck, but switched to the same traction that trams and trains use.

There are controversies about how to get rid of harmful emissions during the transportation of goods. People calculate that batteries or hydrogen cells are more suitable for powering electric motors in large cars. Schmeider is involved in testing another alternative – a system that powers trucks in motion using wires stretched over the road and a pantograph located on the roof of the cab.

In a way, this is a great idea. The system is more efficient because it delivers energy directly from the grid to the motors. The technology saves money and weight as batteries are usually heavy and expensive. A truck powered by wires will only need a battery to drive it from the highway to its destination.

In addition, the system is relatively simple. The German company Siemens, which provided the test equipment, has adapted technologies that have been used for decades on railways and trams.

In a way, this is a crazy idea. Who will pay for the electrification of thousands of kilometers of highway?

Getting rid of truck exhaust is an important part of the fight against climate change and air pollution. Long-haul trucks disproportionately contribute to the emissions of greenhouse gases and other pollutants, as they spend a lot of time on the road.

However, the automakers were divided. The two largest truck manufacturers in the world, Daimler and Volvo, are converting to hydrogen fuel cells. They argue that heavy batteries that provide an acceptable range of travel do not make sense to put on trucks – they take away part of the payload.

Traton, which owns truck makers Scania, MAN and Navistar, argues that hydrogen is too expensive and inefficient fuel in terms of energy consumption. Traton, of which Volkswagen is a major shareholder, on the other hand, is betting on constantly improving batteries – and on electrified highways.

Traton is one of the companies that sponsored the eHighway project south of Frankfurt. In addition to her, Siemens and Autobahn GmbH, the state organization responsible for German highways, are participating in the project. There are also small sections of electric roads in the German states of Schleswig-Holstein and Baden-Württemberg. Also, this technology was tested in Sweden, and in 2017 – in USA near the port of Los Angeles…

So far, the choice of electrified highways in Germany is small – a section of about 5 km in length near Frankfurt, equipped with wires in both directions. The goal is to experience day-to-day use of the system with real shipments of real goods. By the end of the year, this system will be used by about 20 trucks.

Schmeider learned to drive a truck while in the army. He works for the transport company Schanz Spedition, located in the small town of Ober-Ramstadt, located in a hilly and wooded region about 55 km from Frankfurt.

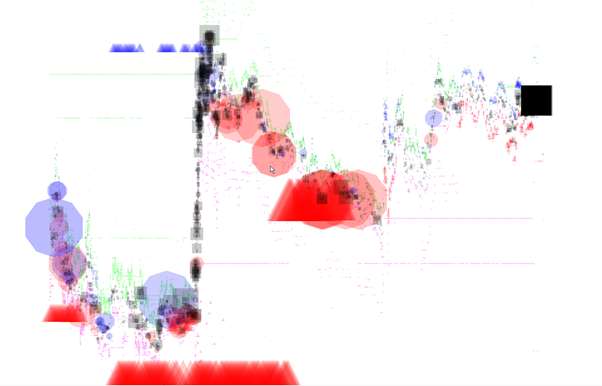

Wires over the road as seen from the truck cab

Video broadcast from the camera looking at the pantograph

If eHighway is ever to be rolled out on a large scale, it will have to be made so that companies like Schanz can work with it. It is a family business run by Kristin Hemmel and Kerstin Seibert, sisters and great-granddaughters of the company’s founder. Their father, Hans Adam Schanz, is technically retired, but was personally behind the wheel of a forklift loading pallets into a truck as Schmeider prepared to set off on his second trip of the day to transport paint to the Frankfurt distribution center.

Business is booming, according to Schmeider, as lockdowns have pushed everyone into home renovations, spurring demand for paint from a factory next door to Schanz’s headquarters.

Schmeider travels the same route up to five times a day. The sponsors of the eHighway project consider such trips to be ideal.

Hasso Grunies, who is in charge of the project from Siemens, said that the most logical thing would be to electrify the most popular routes first – for example, the road from the Dutch port of Rotterdam to Duisburg, a German industrial center. Or it could be a highway connecting the German ports of Hamburg and Lubeck.

Trucks are constantly plying back and forth between these points on the map, Grunies said. Transport companies could make significant savings on their main expense, fuel, which would easily justify the investment in installing pantographs on trucks. In the long term, Siemens estimates that 4,000 km of electrified highways will account for 60% of all freight traffic in Germany. Siemens recently announced that it will partner with parts manufacturer Continental to mass produce pantographs.

However, the task of laying all these wires will fall on the shoulders of the German government. This will cost about € 2.5 million per kilometer.

The German Ministry of the Environment, which has invested in three electrified highways, is comparing the results of their work with the results of driving trucks on hydrogen fuel cells and batteries. The ministry says that in three to four years a decision will be made to support this or that technology.

According to a ministry spokesman, many studies have found that, despite the high cost of building infrastructure, the most effective solution is with wires over the highway. However, this makes batteries cheaper and better and shorter charging times. As stated, “the final choice of technology will take into account the total cost of infrastructure, machinery and energy.”

The government is cautious about this, as there is a risk that taxpayers will pay for highway electrification, and then the trucking industry will abandon this technology, or it will become obsolete due to something new.

According to Gert de Kock, electrification specialist for the Brussels public movement Transport & Environment, “in theory, this is the best idea.” But, according to him, the political obstacles – for example, the harmonization of technological standards between all European governments – are still too great.

“The problem is more coordination than technology,” Kok said. “We do not support it, because we believe that it will not be implemented.”

Thomas Schmeider in a test truck

Schmeider, a truck driver, believes in technology. He got a job at Schanz in 2019, when this test project was just starting – specifically to participate in it.

“I have always been interested in electric transport and its direction of development,” he said as he drove his Scania through the narrow street leading from the Schanz headquarters onto the A5 motorway. A hybrid truck powered by a diesel engine, an electric motor and a small battery, passed a sign pointing to Frankenstein’s Castle – said to have inspired the author of the famous monster novel.

Soon, Schmeider was driving up the A5 overpass, and the poles supporting the eHighway cables above the road became visible. In the cockpit, the change in power was barely felt when Schmeider activated the pantograph reaching to the overhead wires.

The same cables also recharge the truck’s battery, which stores enough energy to travel a short distance in city traffic without harmful emissions. This is another advantage of the system – eHighway can eliminate the need for charging stations, which is very important for the trucking industry, where time is money.

“Infrastructure requires a lot of resources,” wrote Manfred Boltz, an analysis and consulting professor at Darmstadt University of Technology. “On the other hand, it is very energy efficient, and very small batteries are needed to travel outside the cables.”

Schmeider put his hands on the steering wheel while the autonomous driving system brought the truck right under the cables. He and other truck drivers underwent a one-day training course on how to operate the system and troubleshoot problems such as cars blocking the lane. Such cases have already happened to him. He simply taxied out from under the cables to another lane using a diesel engine.

Sometimes there were technical problems. The sensors failed a couple of times. “But there were no big problems,” Schmeider said.

Almost everyone agrees that the biggest obstacle to a global electric road network is not technology. “We have demonstrated that such roads can be built,” Grunyes said. “Now the question is how to build them on a large scale.”